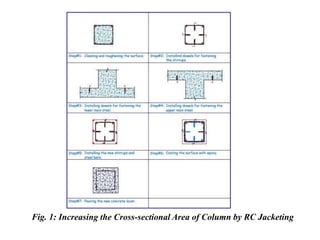

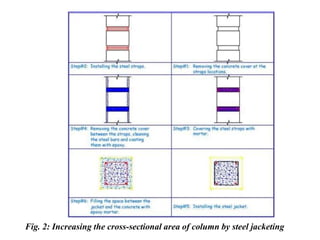

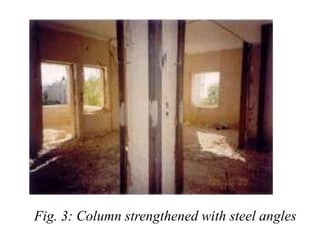

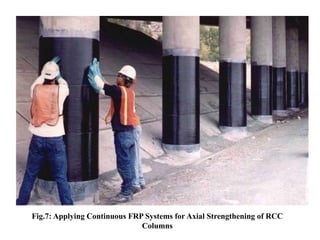

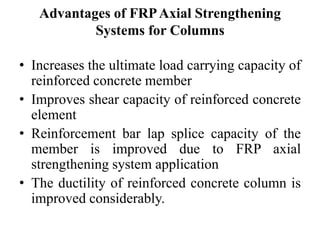

The document discusses concrete jacketing techniques to enhance the load-bearing capacity of structural elements, focusing on reinforced concrete columns. It outlines methods including reinforced concrete jacketing, steel jacketing, and FRP confining, detailing procedures for each technique, such as preparing the substrate and installing reinforcement. The purpose of these techniques is to address design modifications, repair damage, or restore integrity in structural components, particularly due to increased loads or failures.