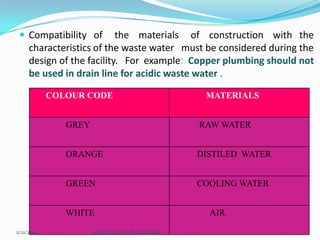

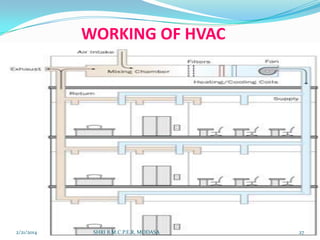

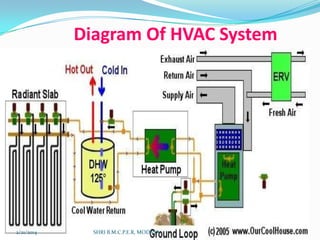

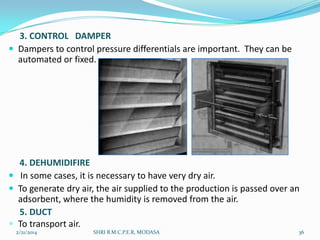

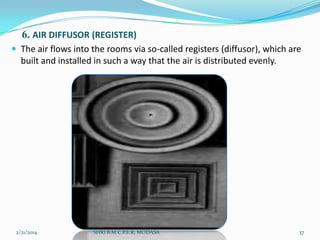

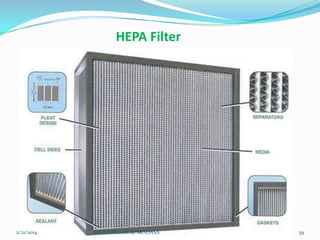

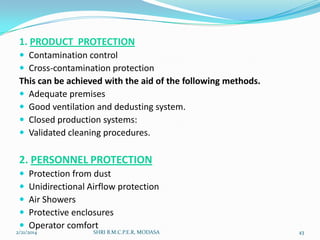

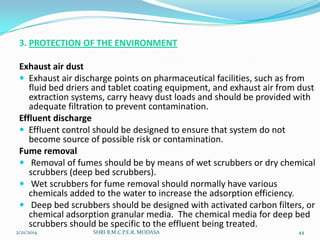

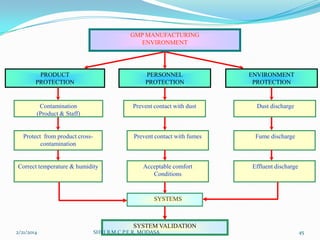

This document discusses utilities and HVAC systems used in pharmaceutical manufacturing facilities. It provides details on various utility services including HVAC, plumbing, drainage, gas, sanitation, water, and fire protection systems. It describes the functions of heating, ventilation, air conditioning, temperature and humidity control, air filtration and flow, and other components of HVAC systems. It emphasizes the critical roles of utilities and HVAC in maintaining environmental controls for sterile and contamination-sensitive areas in pharmaceutical facilities.