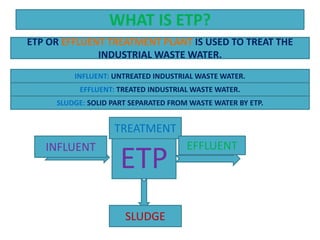

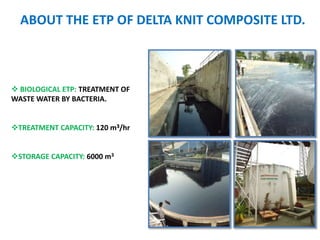

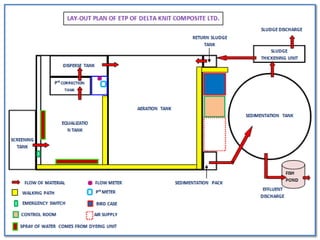

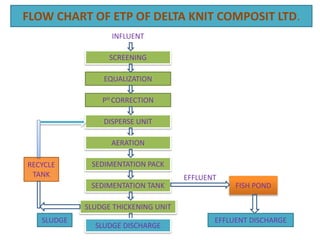

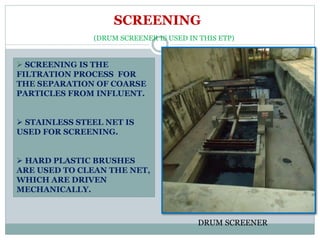

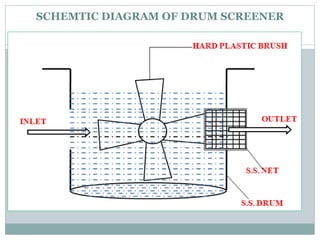

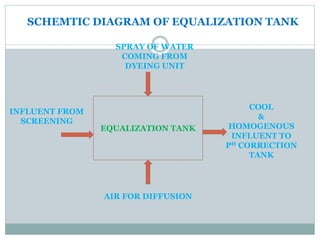

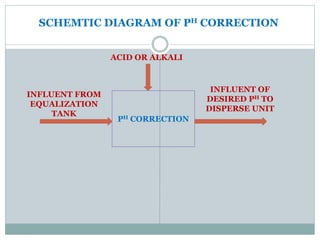

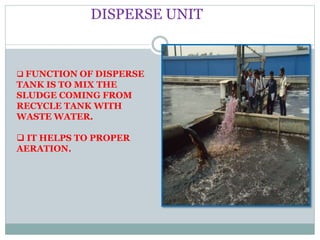

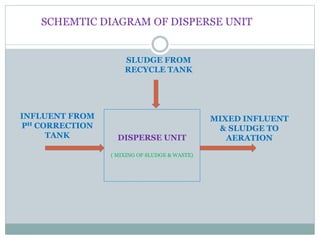

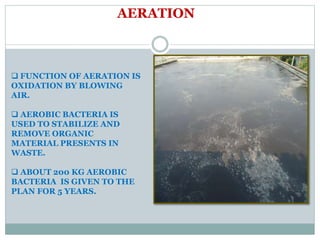

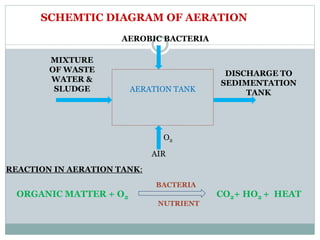

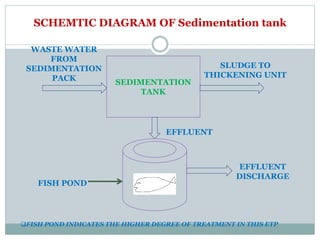

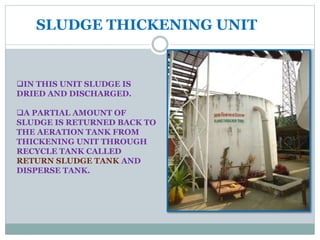

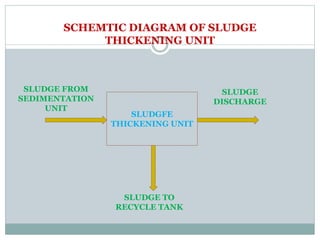

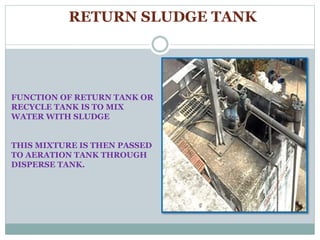

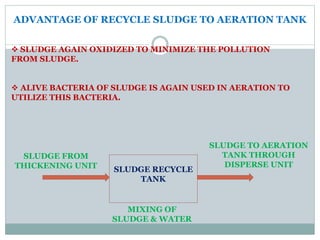

This document provides an overview of the effluent treatment process at Delta Knit Composite Ltd. It describes the various stages of ETP including screening, equalization, pH correction, aeration, sedimentation, sludge thickening, and effluent discharge. The key stages involve using bacteria to biologically treat 120 m3/hr of wastewater over 8 hours in an aeration tank, sedimentation to separate solids from treated water, and sludge thickening before partial recycled is returned to the aeration tank and the remainder is discharged. The multi-stage biological and physical separation process aims to treat industrial wastewater before discharge.