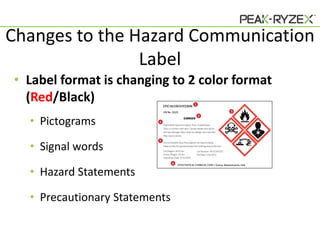

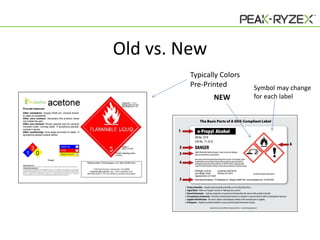

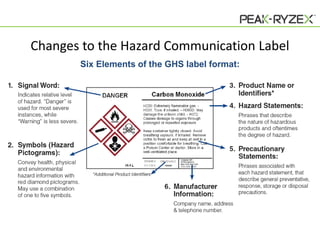

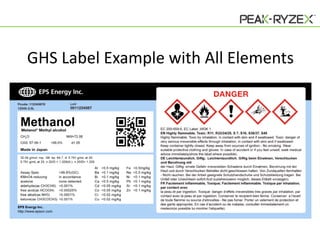

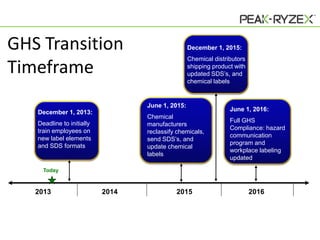

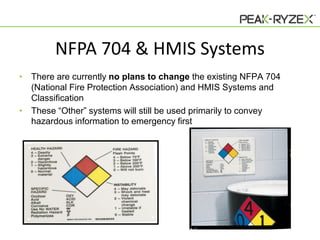

The Globally Harmonized System (GHS) is a standard for labeling hazardous materials, requiring compliance from manufacturers, suppliers, and users of chemicals. It aims to enhance safety, ensure international consistency, and protect workers, potentially preventing numerous injuries and saving lives annually. Transition deadlines for compliance, including new labeling formats and procedures, are set from 2013 to 2016.