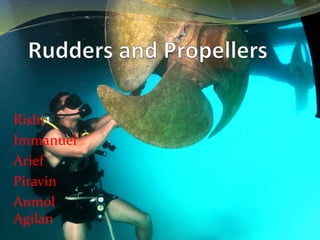

Rudders and propellers

- 5. Spectacle Frames and Bossing. The shaped frames and plating forming the bossing terminate in a casting known as the spectacle frame which provides the aftermost for the shaft. This system totally encloses the shaft withing bossing. Thus the wetted surface area of the hull is increased resulting in greater frictional resistance, however no struts in open water thus total resistance is smaller.

- 6. Advantages 1) No struts to be damaged 2) Greater protection of the shaft 3) Access to shafts and bearings for a greater proportion of the length

- 8. May be cast or fabricated, particular attention being paid to the strut section to avoid increase in resistance and cavitation. The connections to the main hull are of particular important since considerable rigidity of the structure is required.

- 9. Disadvantages 1. Larger resistance than bossing due to the various strut each causing eddies thus increasing resistance. 2. The struts are liable to damage if hit by floating objects. 3. The propeller shafts themselves are more liable to damage. 4. Access to the bearings is limited to dry-docking.

- 10. Rudders

- 11. Types of rudder The main purpose of balancing rudder is to achieve the reduction in the torque required of the steering gear. • there are 3 types of rudders: balanced: a portion of the blade area is disposed symmetrically through the rudder height and fwd of stock unbalanced: blade is entirely aft of stock semi-balanced: area fwd of stock does not extend to the full height of the blade aft of the stock – upper portion may be considered unbalanced and the lower portion, balanced

- 12. Balanced Rudder Axle fitted at its turning axis with large area forward of the axis (25% to 30 %). Upper and lower bearings are fitted in the rudder. The bearing consists of a stainless steel bush in the rudder and a stainless steel liner on the axle. The stainless steel bush is spirally grooved to permit lubrication. Other materials are in use, such as gun metal for liner and lignum vitae or tufnol for the bush.

- 13. UPPER BEARING LOWER BEARING BOLTED PALM RUDDER STOCK LIFTING TUBE VERTICAL WEB HORIZONTAL WEB DRAIN PLUG RUDDER AXLE BALANCED RUDDER13

- 14. Unbalanced Rudder Full area aft of the axis. Fitted with upper, mid and lower arms rested on gudgeons. At the bearing pintle fitted with hard steel disc and locking nut. The ordinary pintle arranged with bush and locking nut and the locking pintle at the top part of the rudder secured by locking nut.

- 15. Turn on pintles and have a small portion of their lateral area forward of the turning axis (less than 20%). Commonly fitted on twin screw vessels where most of it hinged on a body post by pintles and gudgeons.

- 16. RUDDER STOCK HORIZONTAL WEB VERTICAL WEB LIFTING TUBE DRAIN PLUG RUDDER POST GUDGEON LOCKING PINTLE BEARING PINTLE UNBALANCED RUDDER

- 17. Semi-Balanced Rudder Which are very common today. Have less than 20% of the lateral area forward of the axis. Modern ships’s use this design of ruder.

- 18. Rudder Pintles Pintles are found on all 3 types of rudders. Pintles on which the rudder turns in the ‘gudgeons’ have a taper on the radius, and a bearing length which exceeds the diameter. They not only act as ‘hinges’ but also take lateral loads and transfer them to the frame, thus reducing the stresses on the stock and coupling.

- 19. Locking pintles are designed to prevent the rudder lifting. Bearing pintles take part of the rudder’s weight

- 20. Bearing Pintle

- 21. Locking Pintle

- 22. Ordinary Pintle

- 23. The Propeller

- 24. Propellers Propellers may have from 3 to 6 similar blades depending on the design requirements. It is important that the propeller is adequately immersed at service drafts and that there are good clearance between its working diameter and the surrounding hull structure.

- 25. Types of Propellers: Fixed Pitch Propeller Controllable Pitch Propeller

- 26. Fixed Pitch Propeller The blades in fixed pitch propeller are permanently attached to the hub. The fixed pitch type propellers are casted and the position of the blades and hence the position of the pitch is permanently fixed and cannot be changed during the operation.

- 28. Controllable Pitch Propeller In Controlled Pitch type propeller, it is possible to alter the pitch by rotating the blade about its vertical axis by means of mechanical and hydraulic arrangement. This helps in driving the propulsion machinery at constant load with no reversing mechanism required as the pitch can be altered to match the required operating condition.

- 30. Shaft revolutions. Apart from the direct influence on propeller efficiency the choice of shaft RPM depends upon the gearing available, critical whirling speeds of shafts and avoidance of the fundamental frequencies of hull vibrations. Number of blades which influence vibration and cavitations. The wake in which the propeller is to operate. Factors to be considered when designing a propeller

- 31. Propeller diameter and hence clearance between propeller tips and the hull which has a marked effect on vibration. Blade area. The greater the blade area for a given thrust the less likely is cavitation. Boss diameter. Dictated mainly by strength considerations Geometry of the blades, e.g. pitch, camber

- 32. Propeller cavitation Cavitation occurs on propellers (or rudders) that are heavily loaded, or are experiencing a high thrust loading coefficient.

- 34. Stern Tube Fitted to provide a bearing for the Tail End Shaft and so to enable a watertight gland to be fitted at its an accessible position. Withdrawal of the tail end shaft is necessary every three years(four years for ships with two or more screws) if fitted wit continuous liners or oil glands, in all other case every two years.

- 36. Titanic now and then

- 37. Thank you and have a good day!