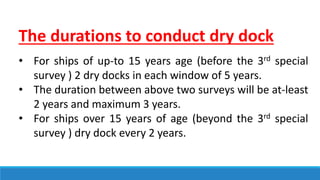

Dry docking involves docking a vessel to expose its entire wetted area for inspection, maintenance, and repair work. It is required by classification societies on a periodic basis to conduct docking surveys and maintain the vessel's class. The key areas inspected during dry docking include the ship's hull plating, sea suctions, propeller, rudder, and anchor system. Careful consideration of the vessel's stability is also important when positioning it on keel blocks in the dry dock and refloating it.

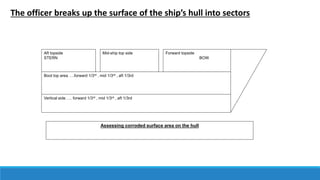

![When asking for quotations for hull fabric maintenance it is necessary to make an accurate

assessment of corrosion on the side shell and also the area of various sectors as follows:-

Formulae for Accessing area

underwater area = [ (2X Keel to waterline + Breadth ] X LBP X block co.eff

also :- Wetted area = 2.58 X displacement X LOA

Underwater Vertical sides area = (2 X Keel to waterline) X LCB X (Breadth / 2)

Dry vertical side area = 2 X Freeboard X { LOA +( Breadth/2)}

Boot top strip = 2 X Bw X {LBP + (breadth /2)}

Flat bottom = u/w area – wetted vertical sides (as calculated above)](https://image.slidesharecdn.com/shipdrydocking-160223160328/85/Ship-dry-docking-13-320.jpg)