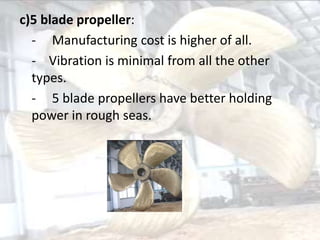

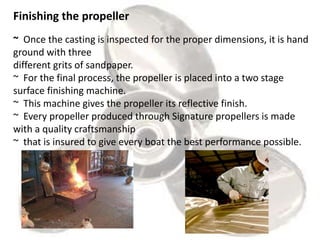

This document discusses the production process of propellers. It begins by describing what a propeller is and its main functions. It then outlines the different types of propellers based on the number of blades and materials used. The production process is then summarized in 3 steps: 1) the tooling is made using CNC milling to create a wax mold, 2) the lost wax process is used to create a ceramic shell around the wax mold which is then melted and replaced with molten metal, 3) the casting is finished through grinding and polishing. Finally, the suitable heat treatment process is described which involves heating the wax mold to create a pattern, dipping it in ceramic to strengthen the mold, then using high heat