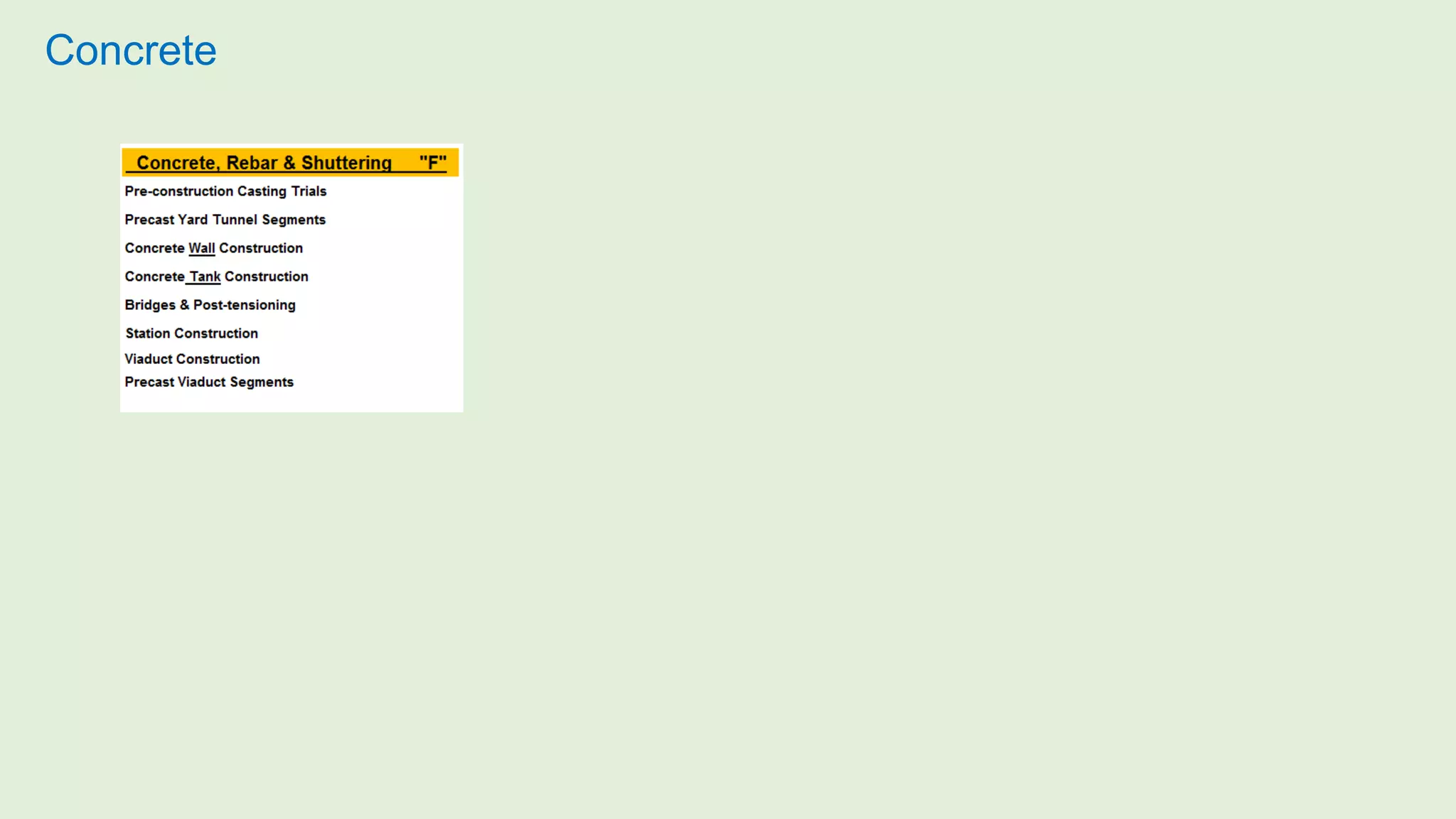

The document provides details on the construction of the Metro Route 2020 project in Dubai, which has a budget of $2.9 billion. It includes key project facts such as a route length of 10.5km for viaducts and 4km for tunnels. There will be 7 underground and elevated stations serving a capacity of 46,000 passengers per hour. Construction will involve tunnelling, precast segment erection, bridge and viaduct construction using methods such as diaphragm walls, secant piles and slipforming. The project execution plan outlines the construction process and measures to ensure safety, quality and environmental protection.