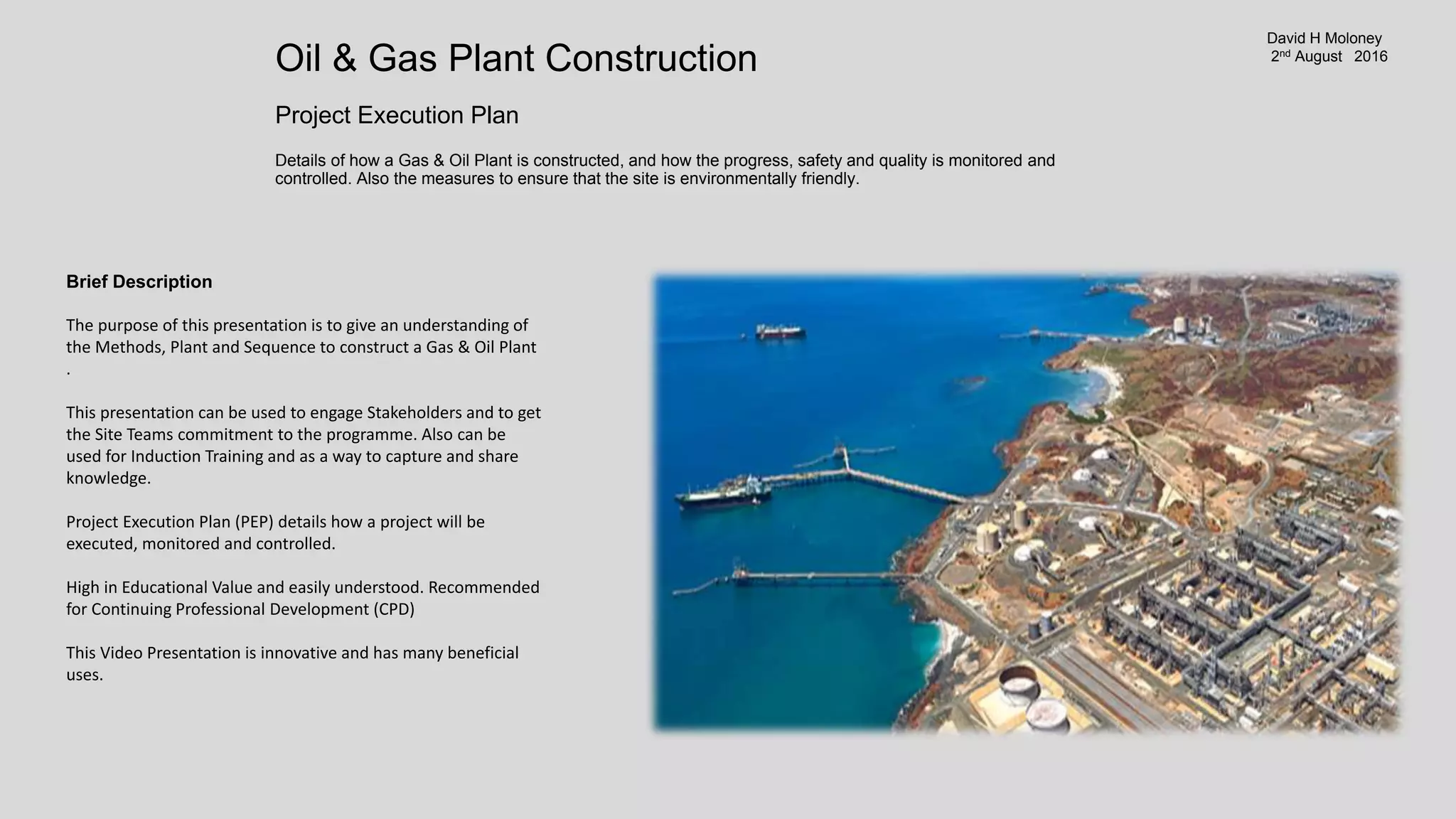

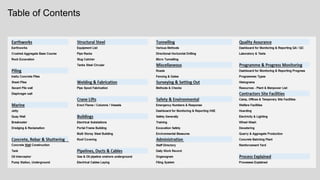

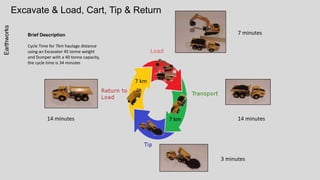

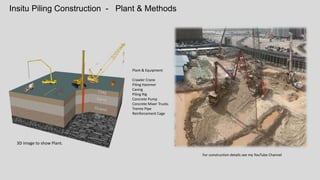

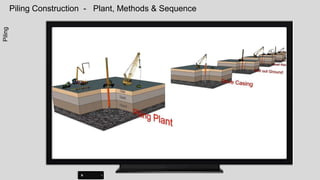

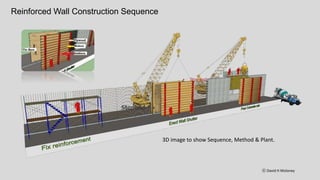

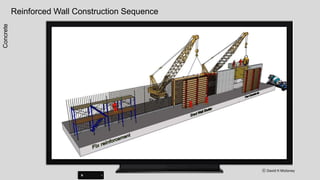

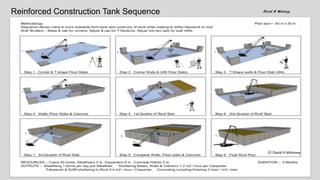

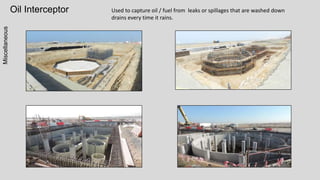

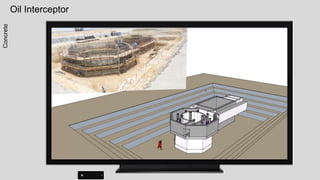

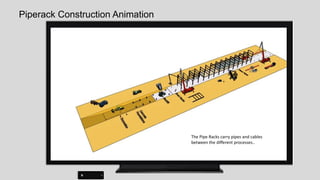

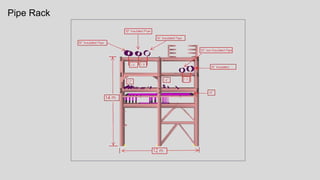

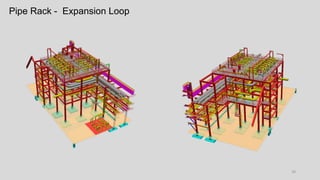

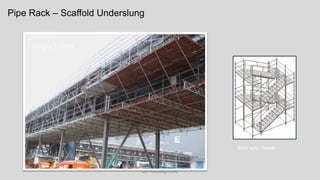

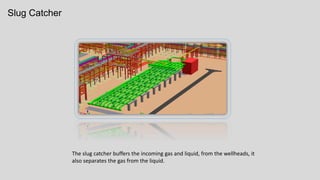

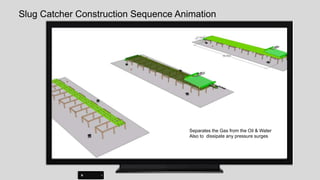

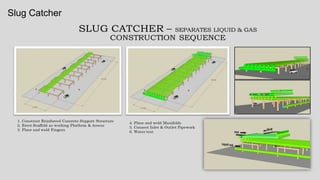

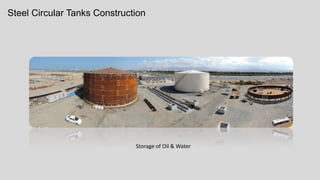

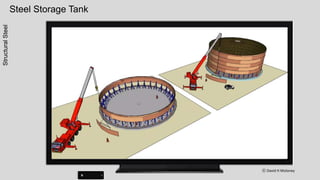

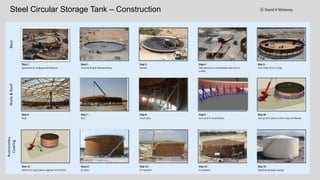

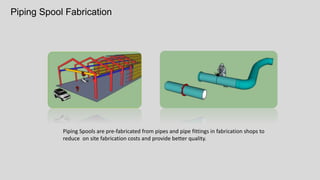

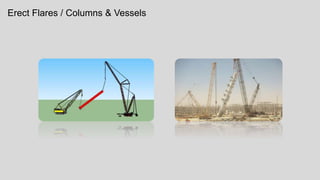

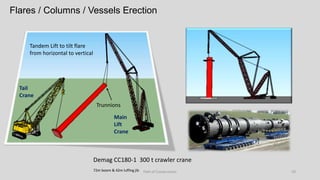

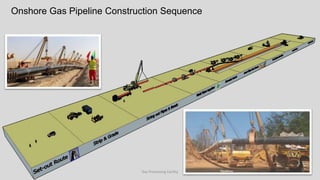

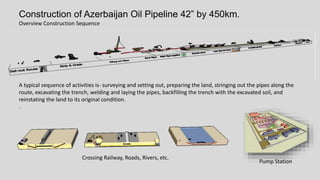

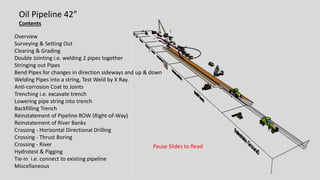

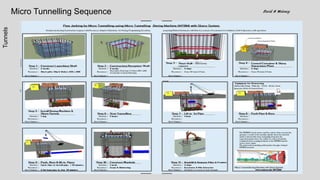

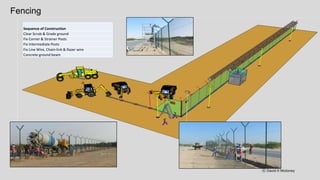

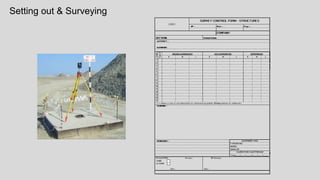

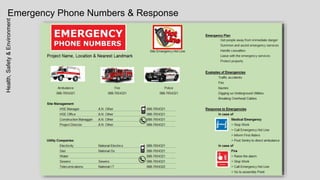

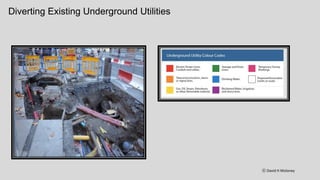

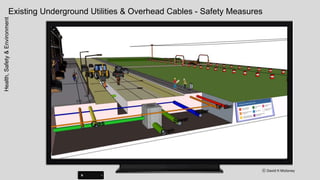

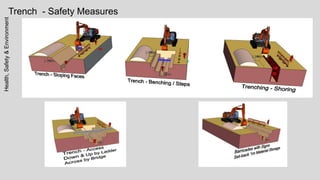

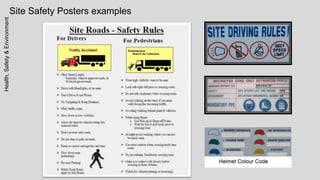

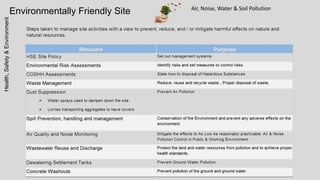

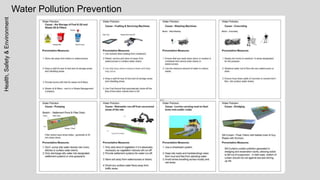

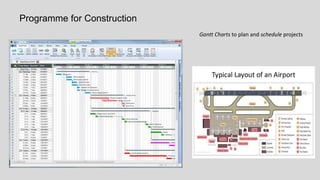

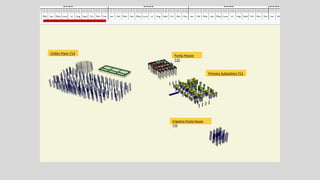

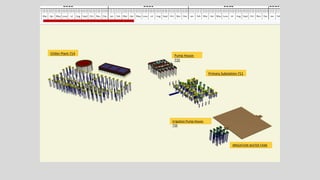

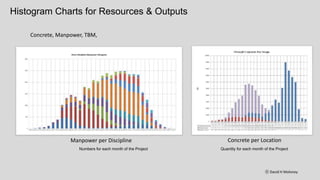

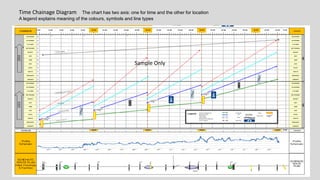

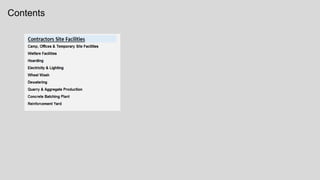

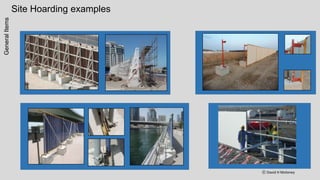

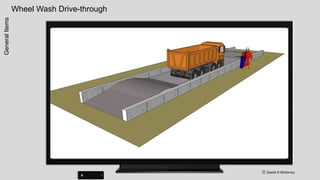

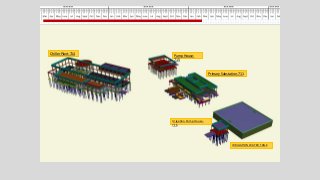

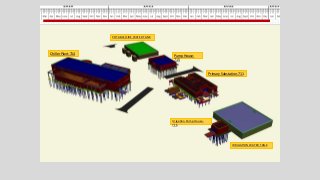

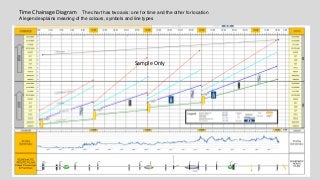

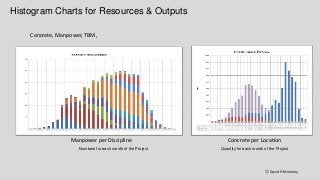

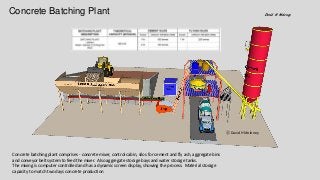

The document outlines the construction execution plan for an oil and gas plant, detailing methods, monitoring procedures, safety measures, and environmental considerations throughout the project. It serves as an educational tool for stakeholder engagement, commitment from site teams, and induction training. Various construction processes, equipment used, and safety guidelines are highlighted, providing a comprehensive overview of project management and execution in the oil and gas sector.