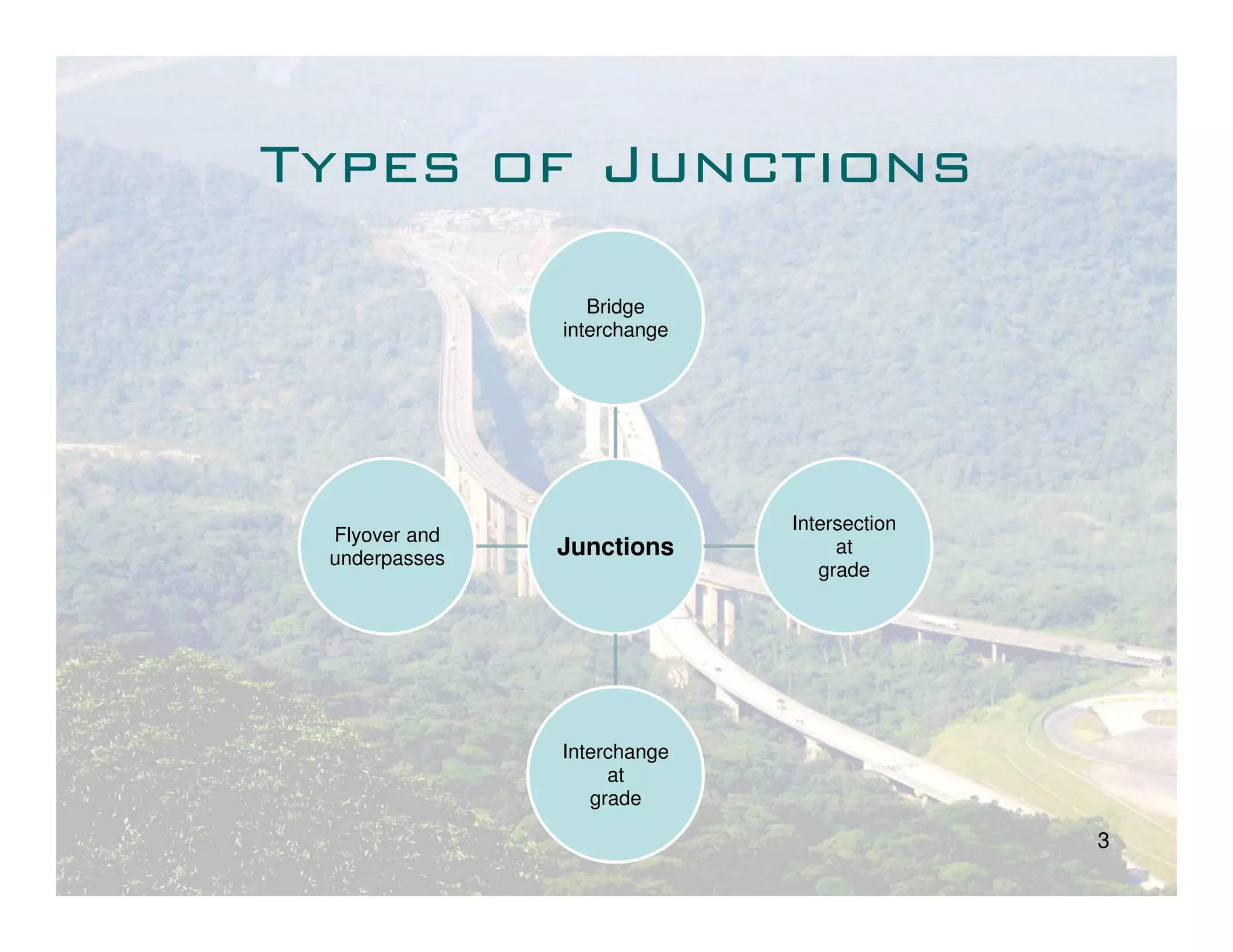

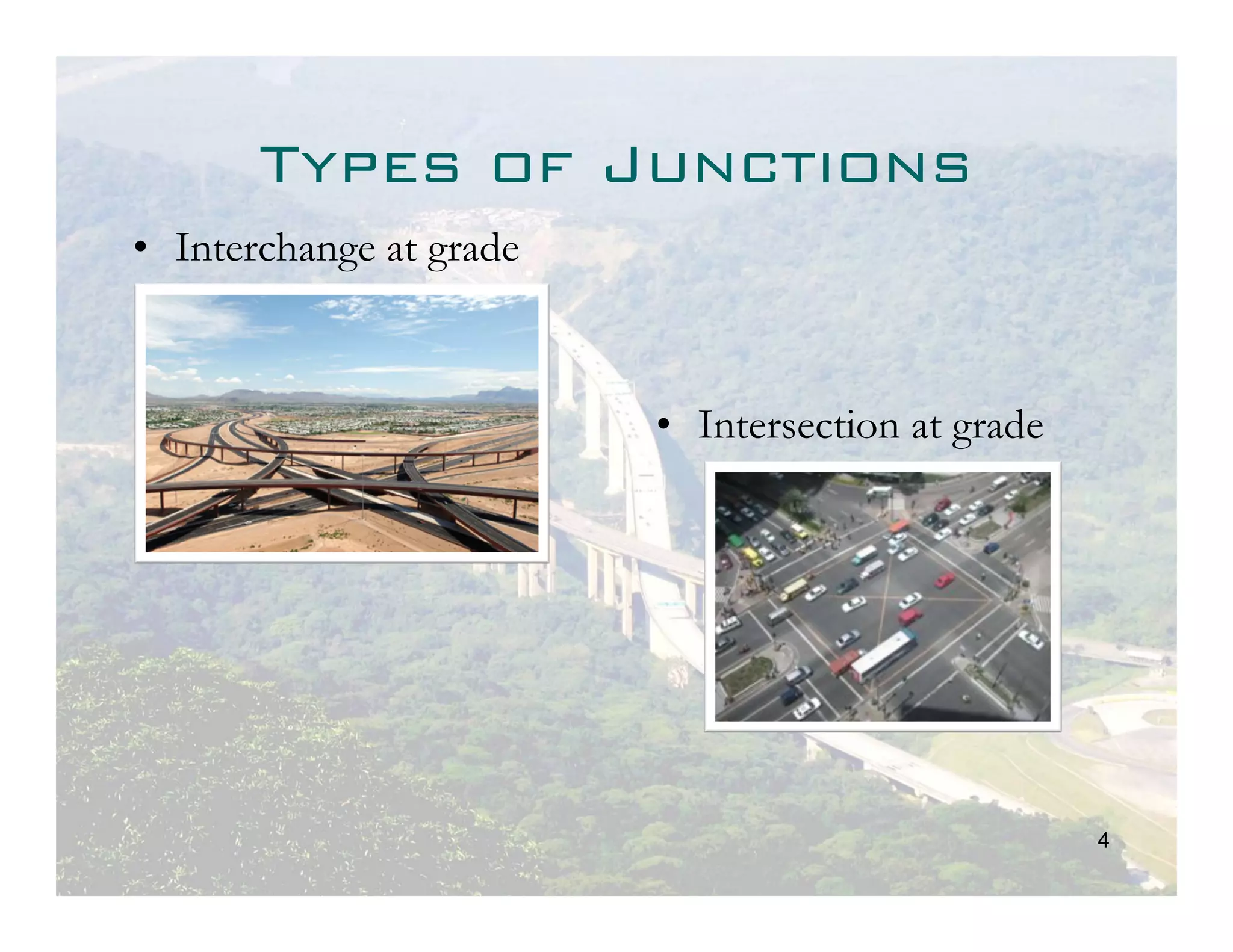

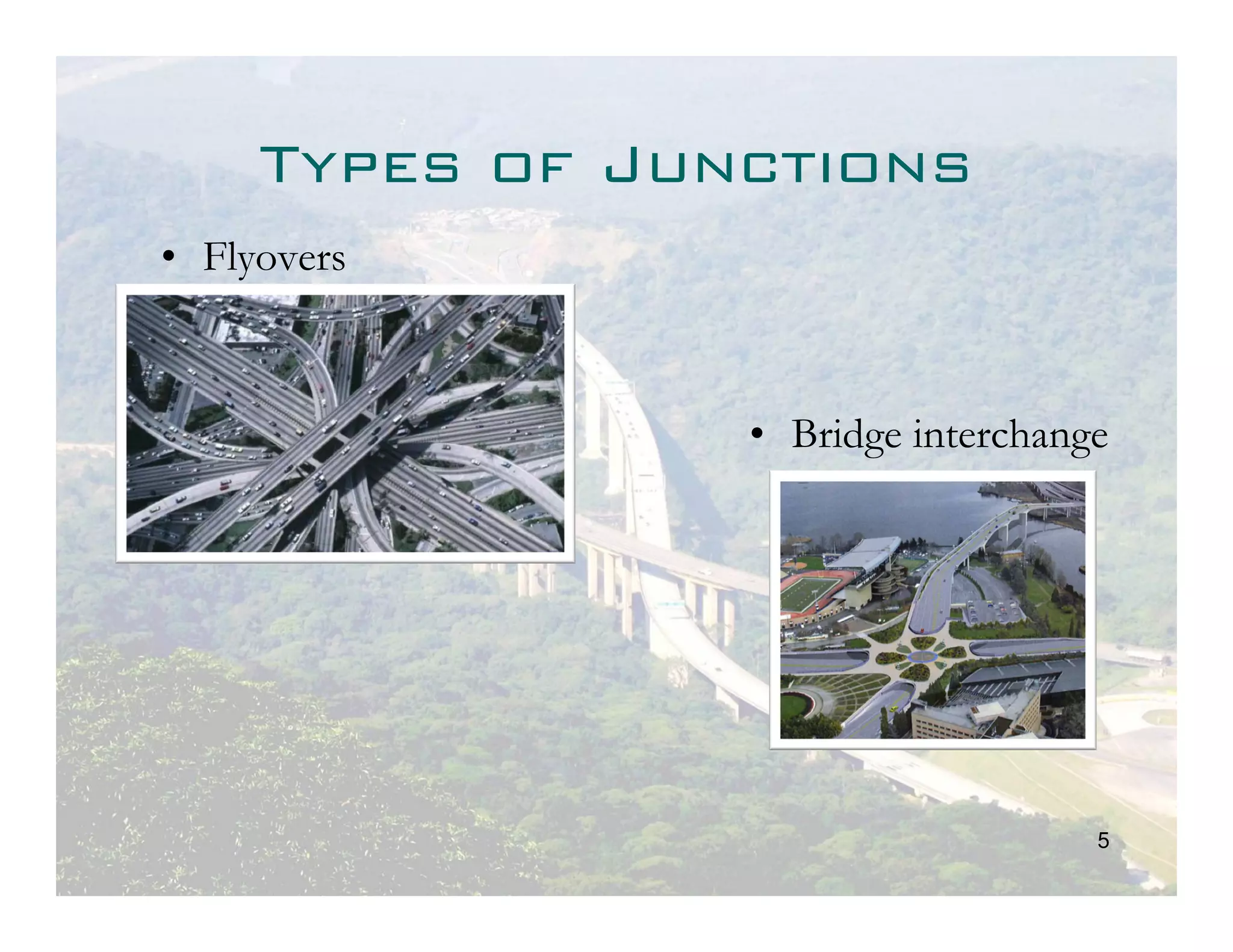

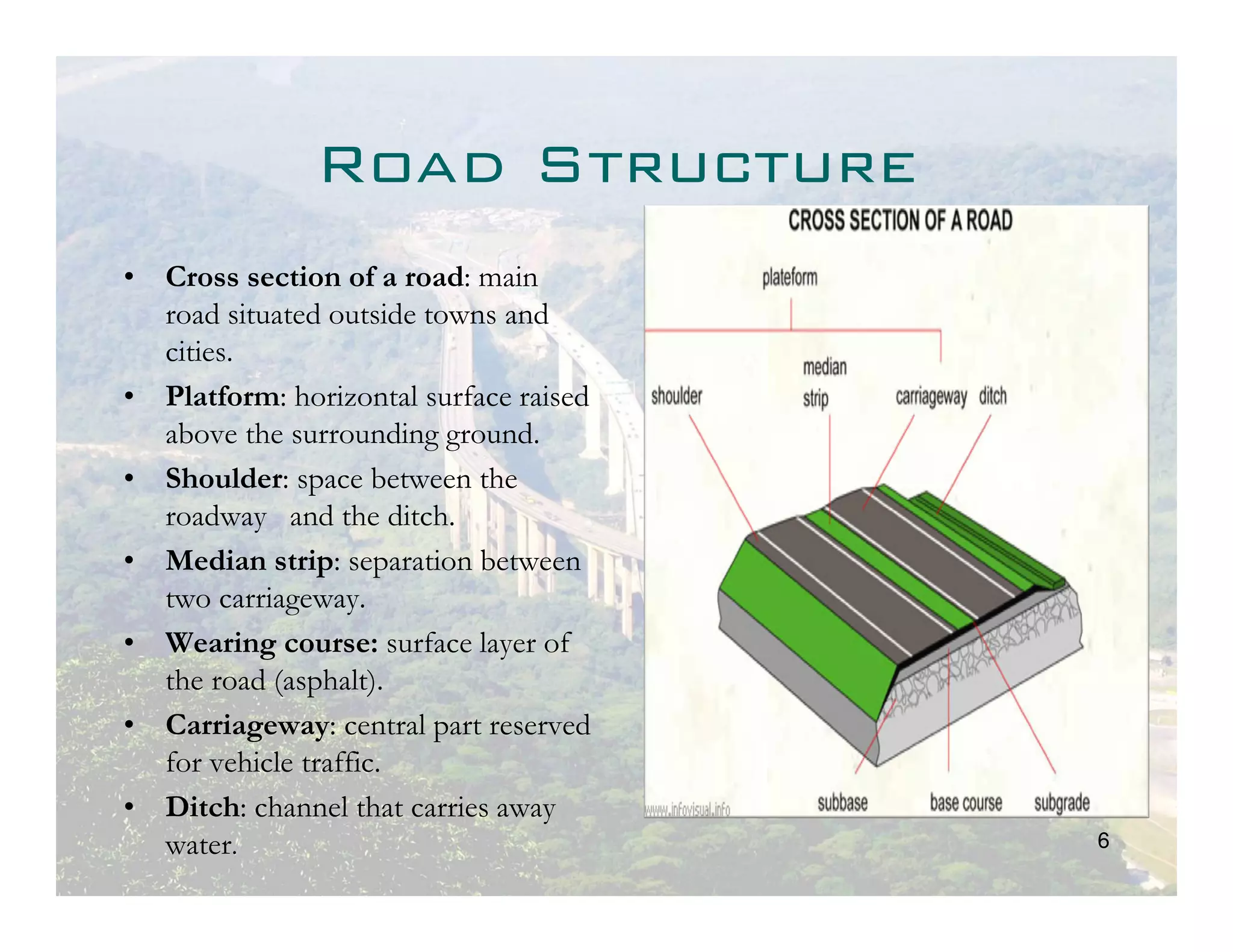

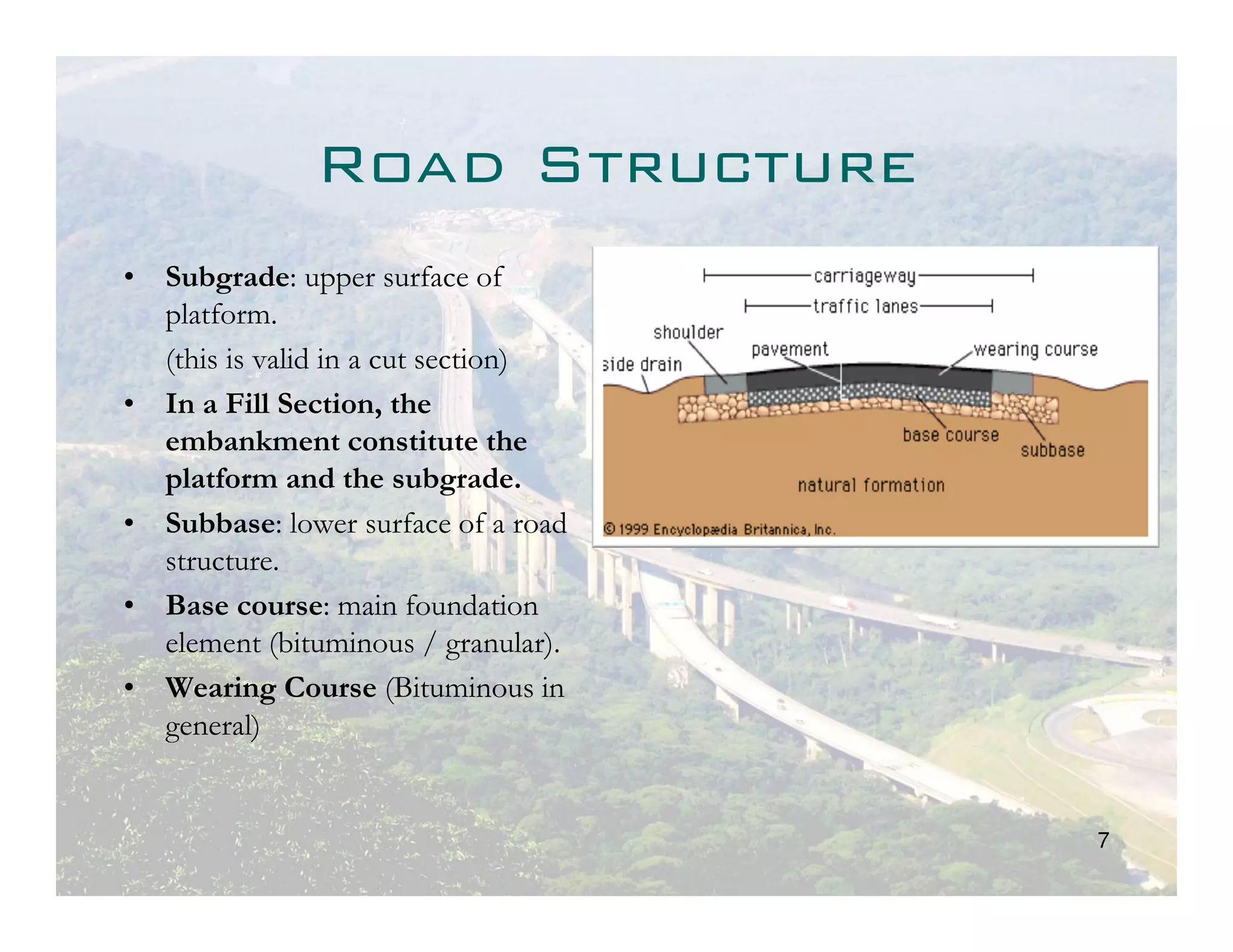

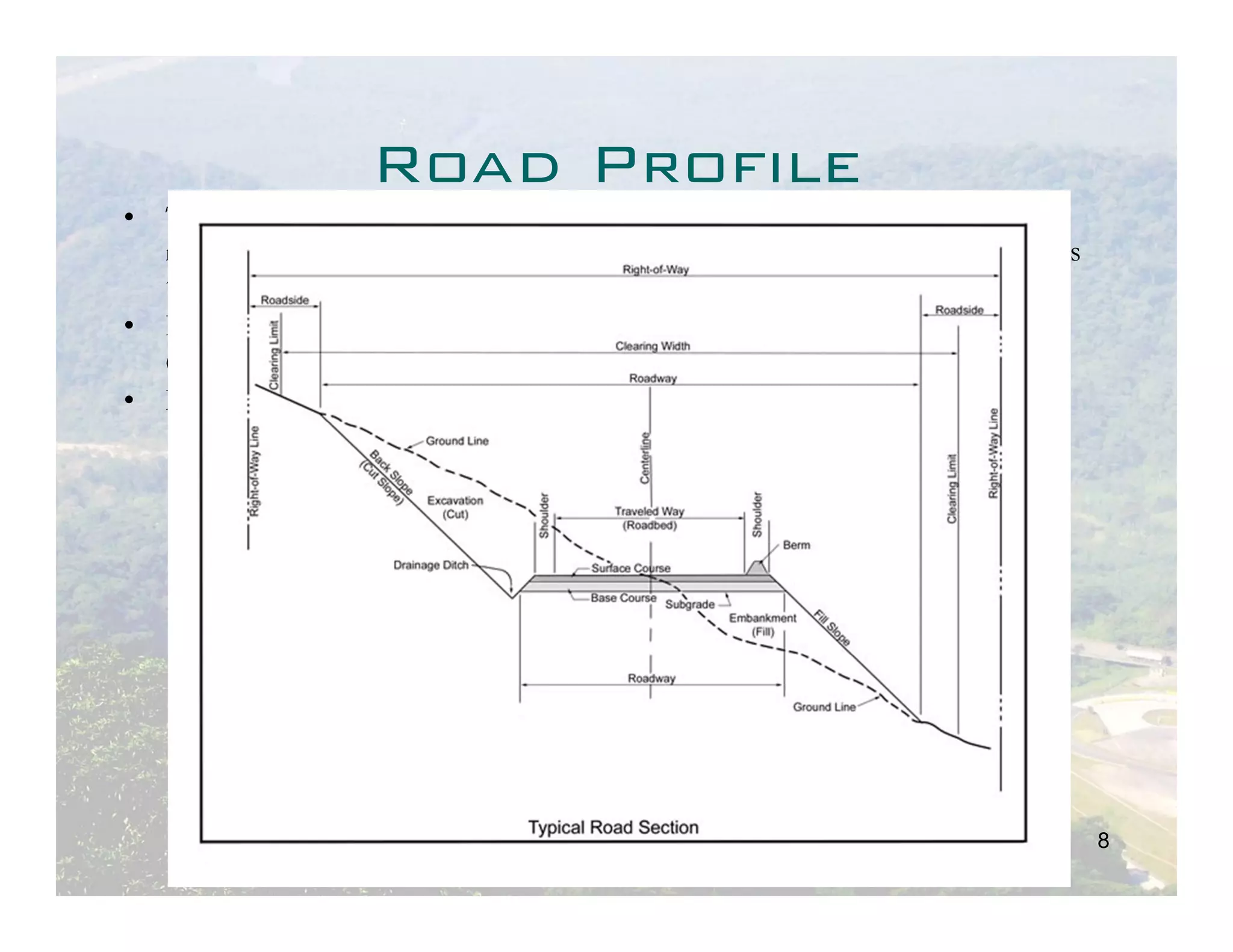

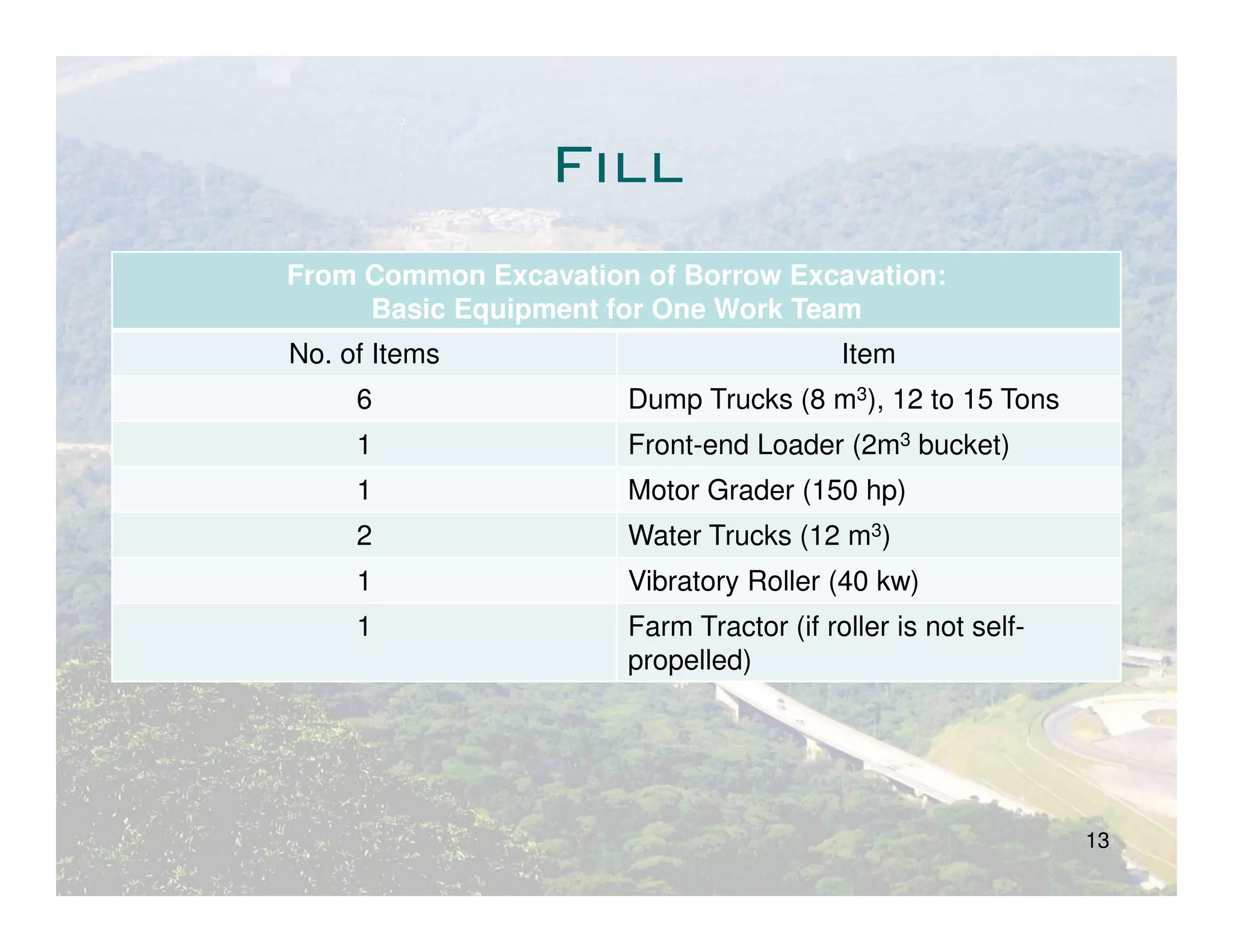

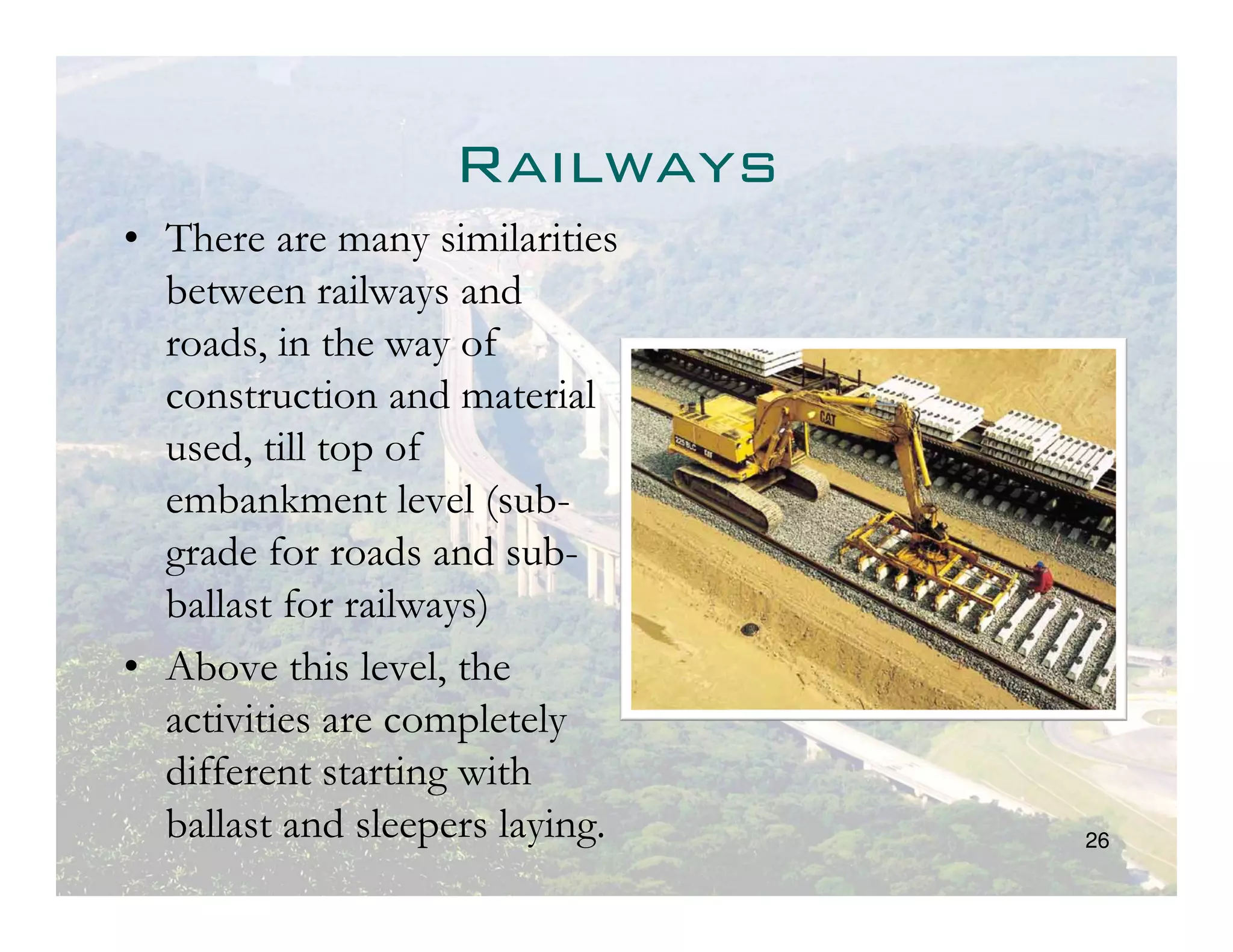

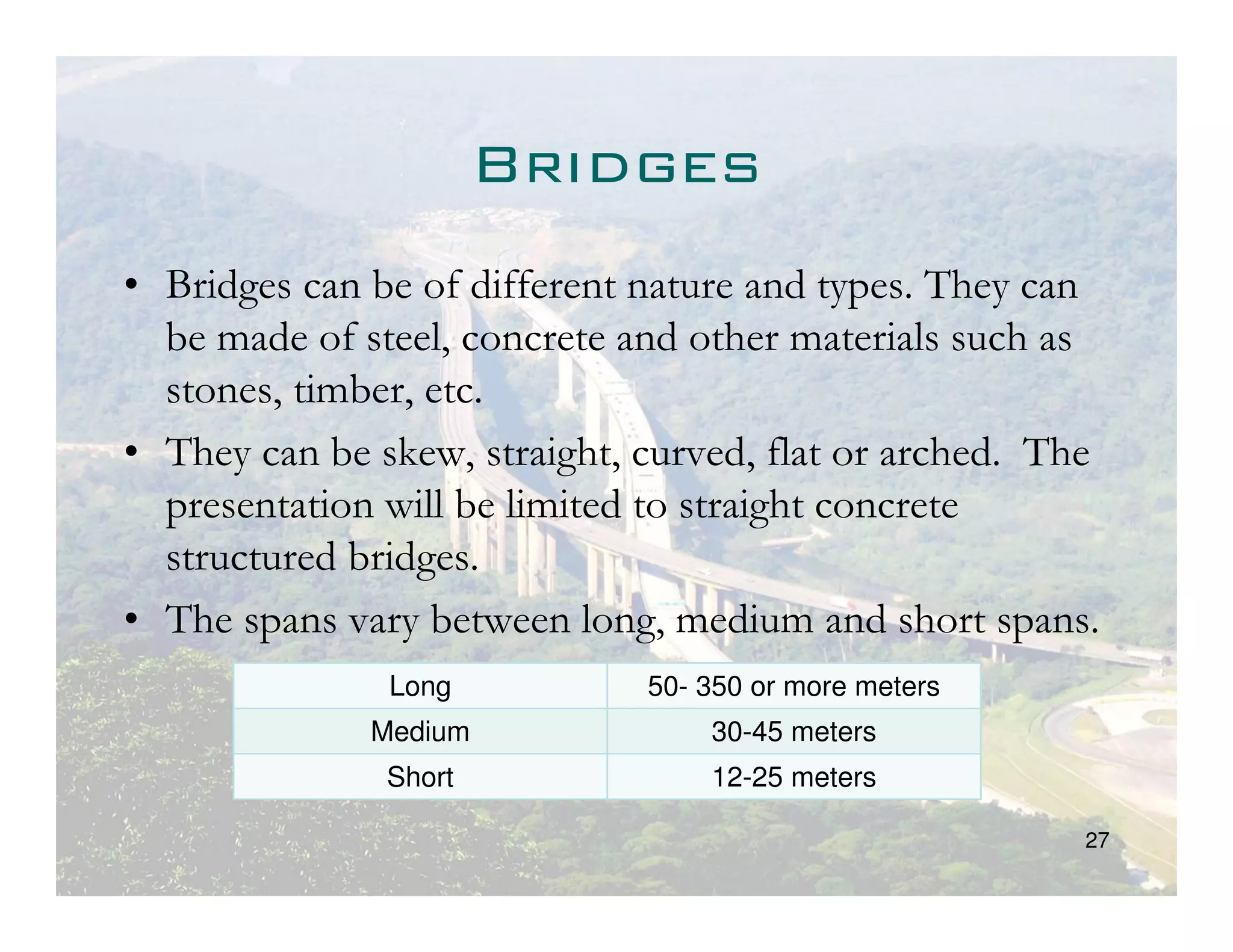

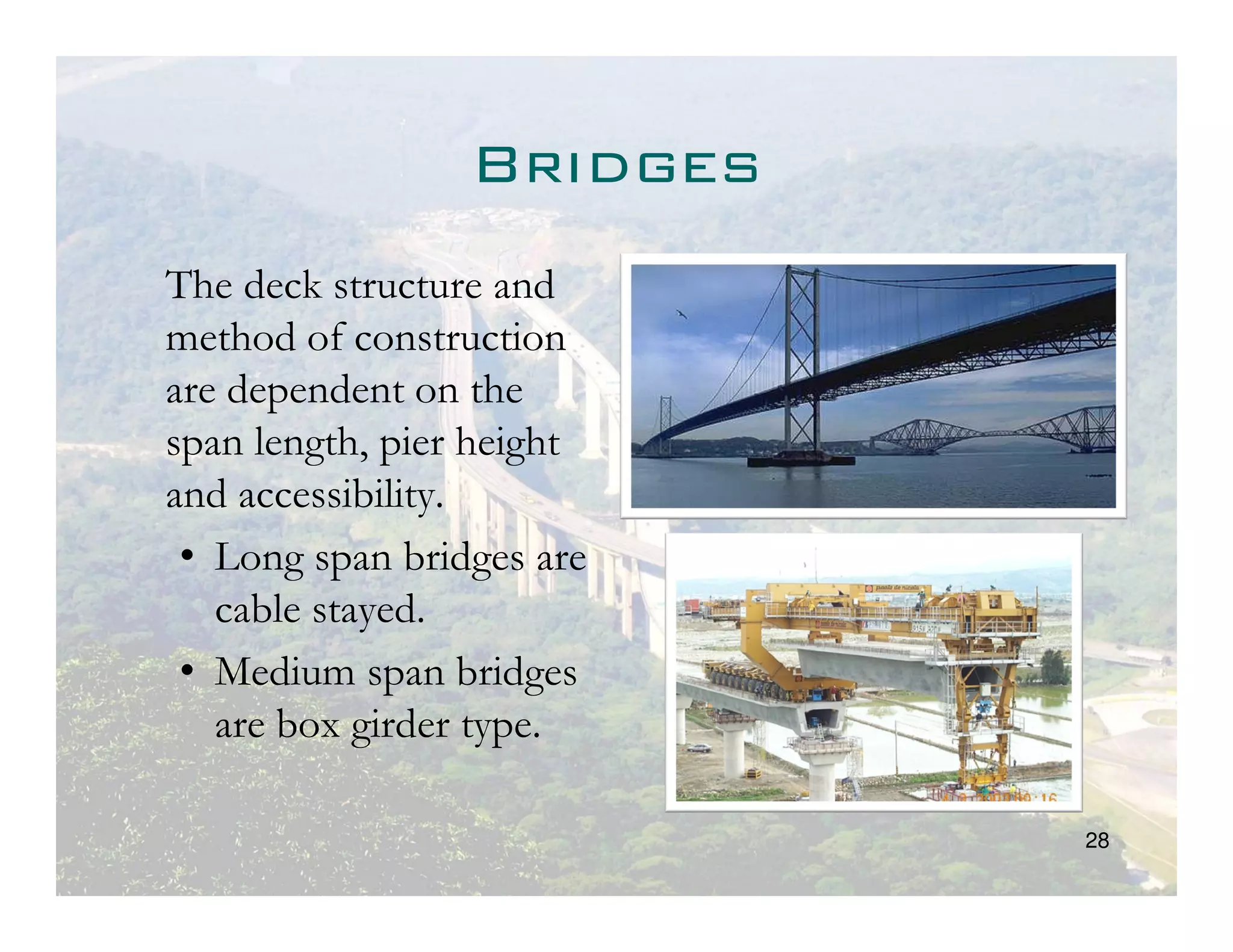

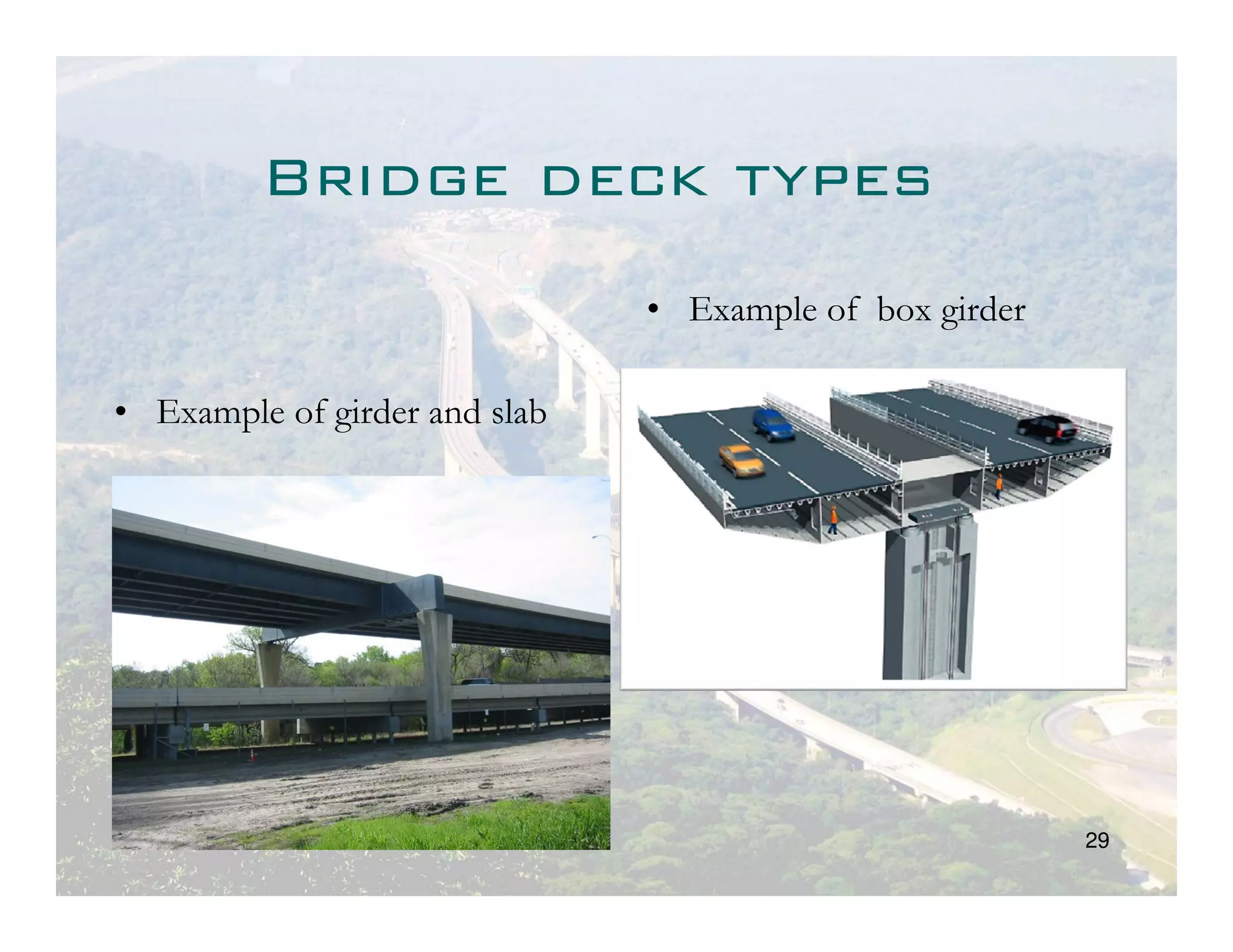

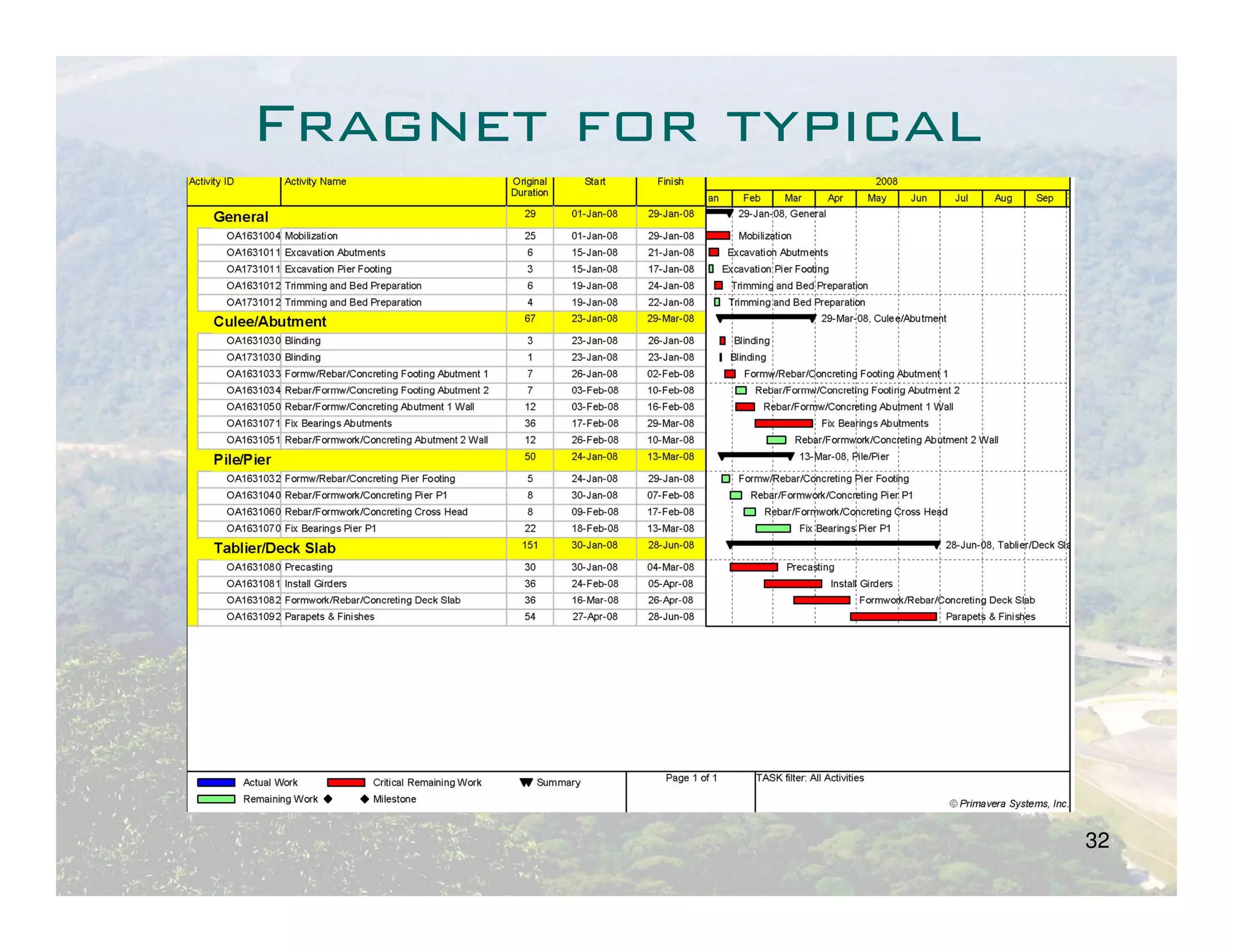

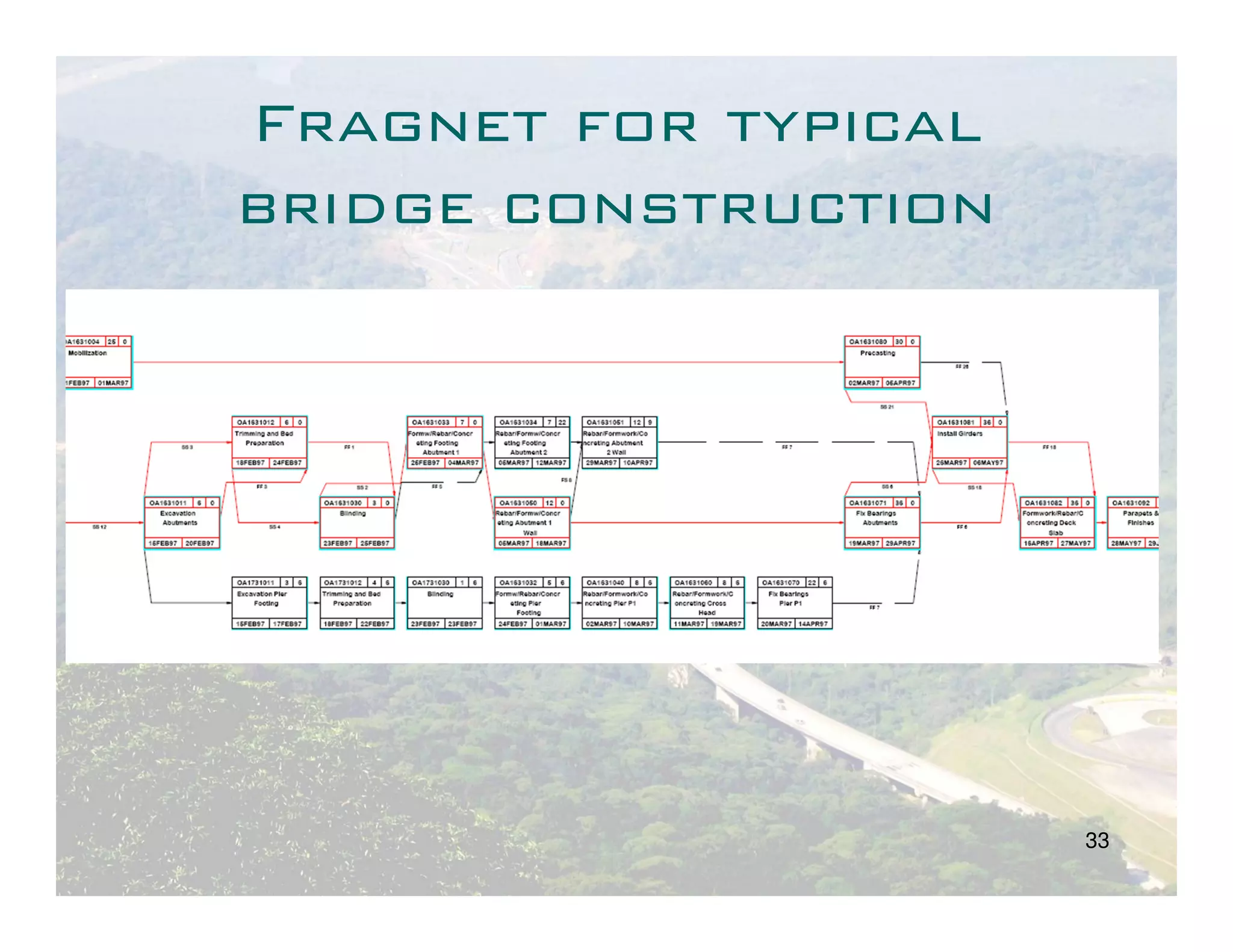

The document discusses various types of roads, bridges, and construction methods. It describes different types of roads including highways, freeways, and motorways. It also discusses different types of junctions like interchanges, intersections, flyovers, and underpasses. The document then describes the typical structure of a road including components like the platform, shoulder, median strip, carriageway, and ditch. It also discusses road profiles, materials used in construction, and road furniture. Finally, it provides information on bridge types, construction methods, and a sample schedule for a typical bridge construction project.