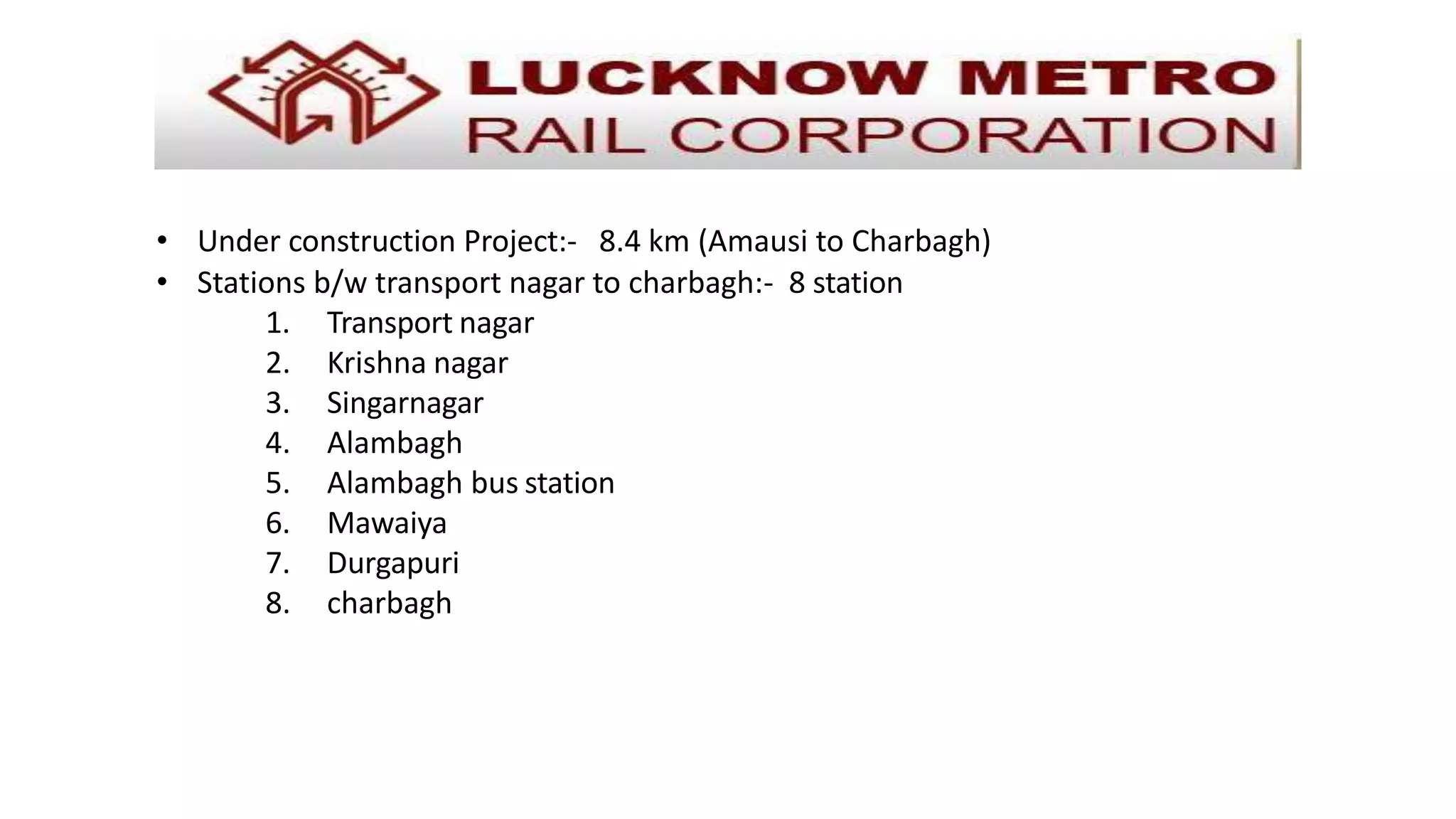

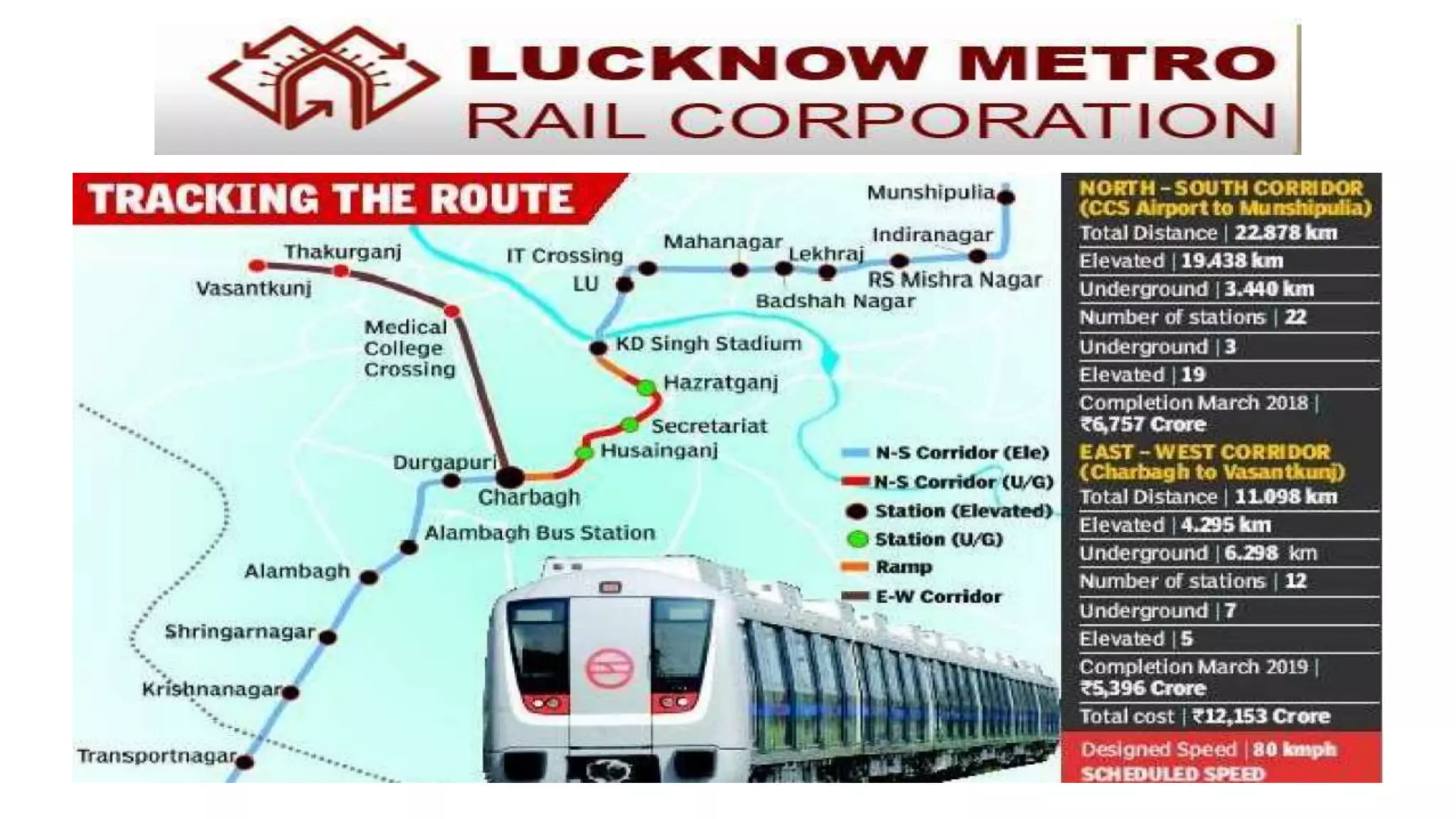

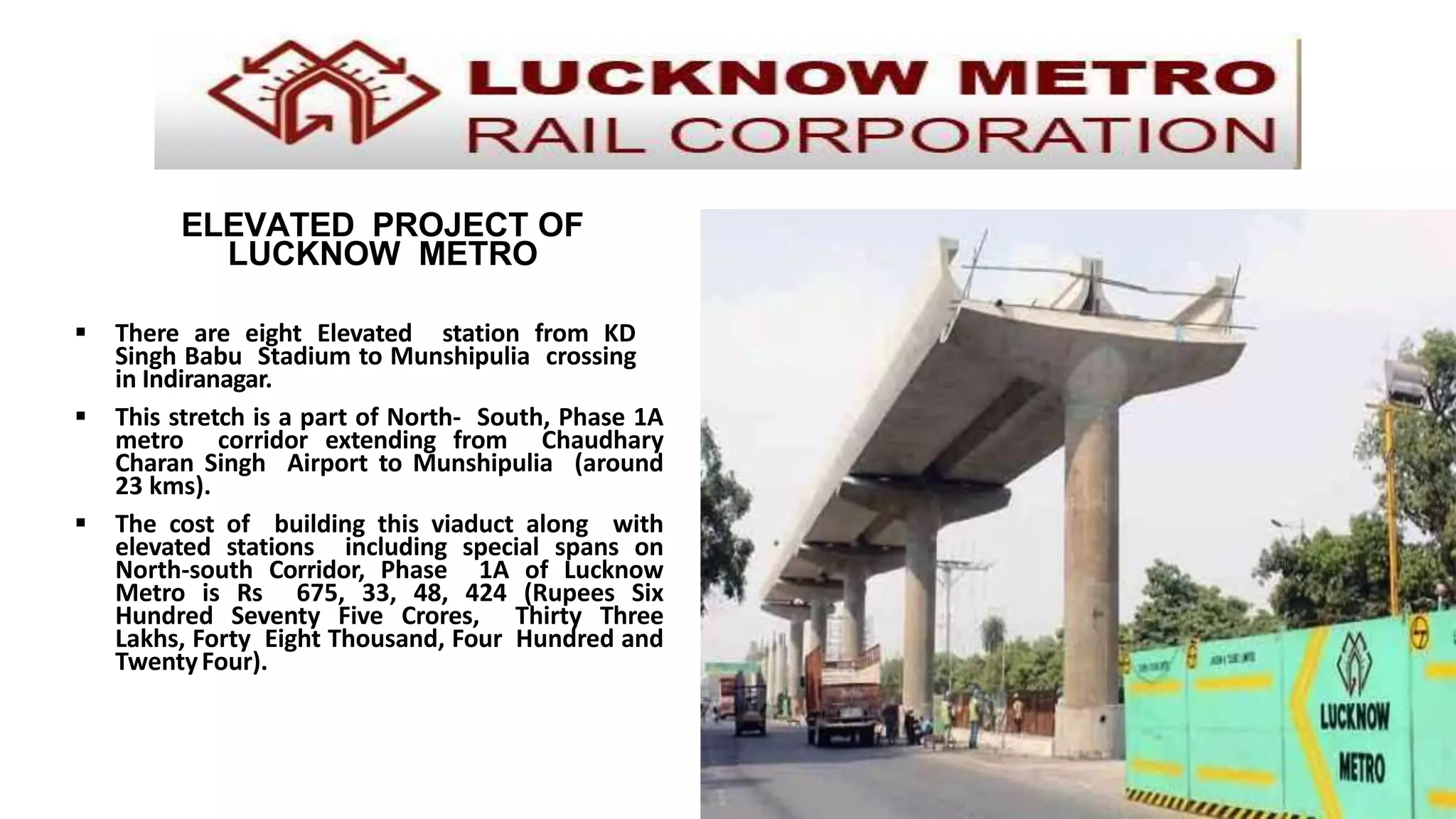

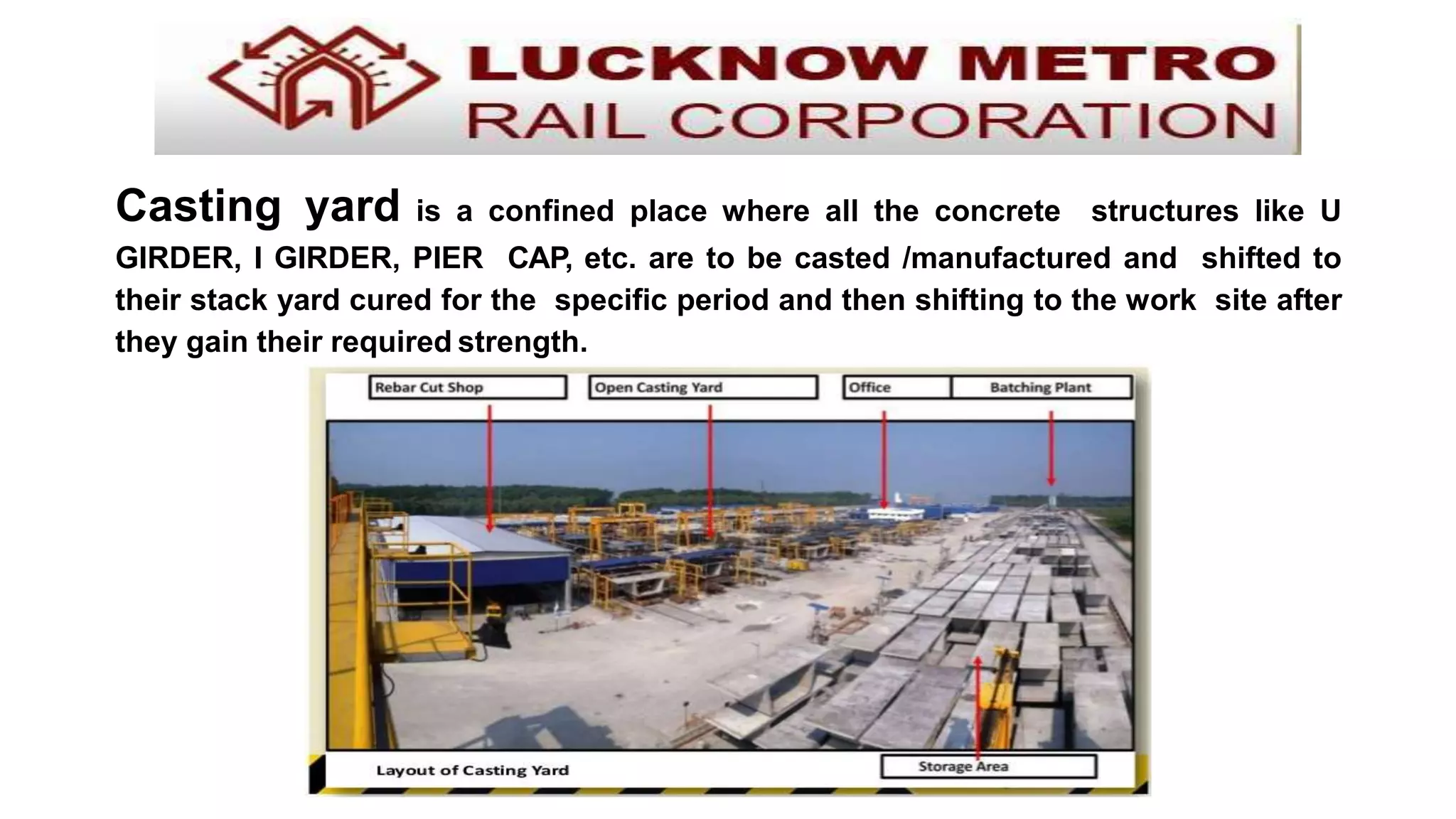

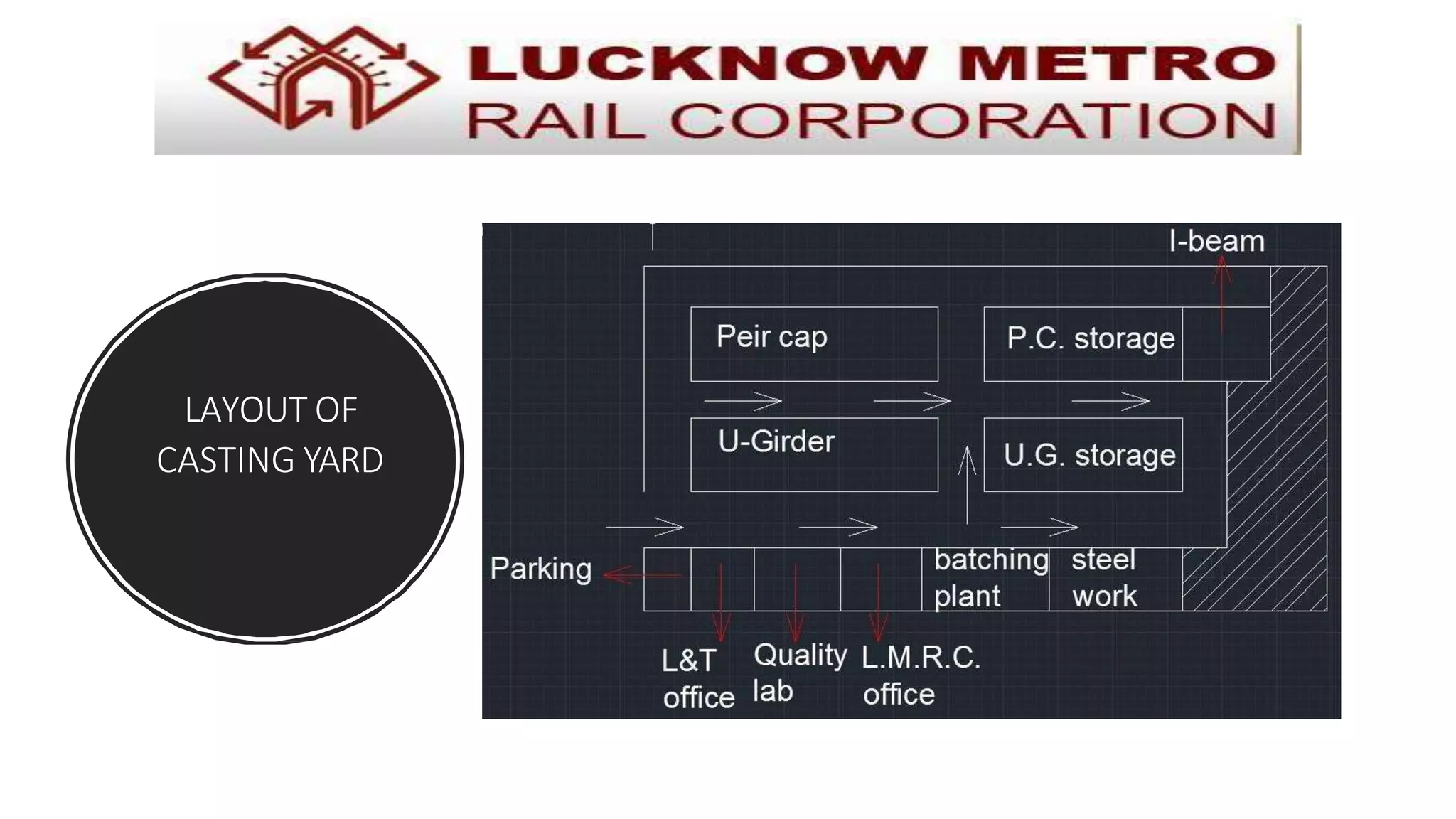

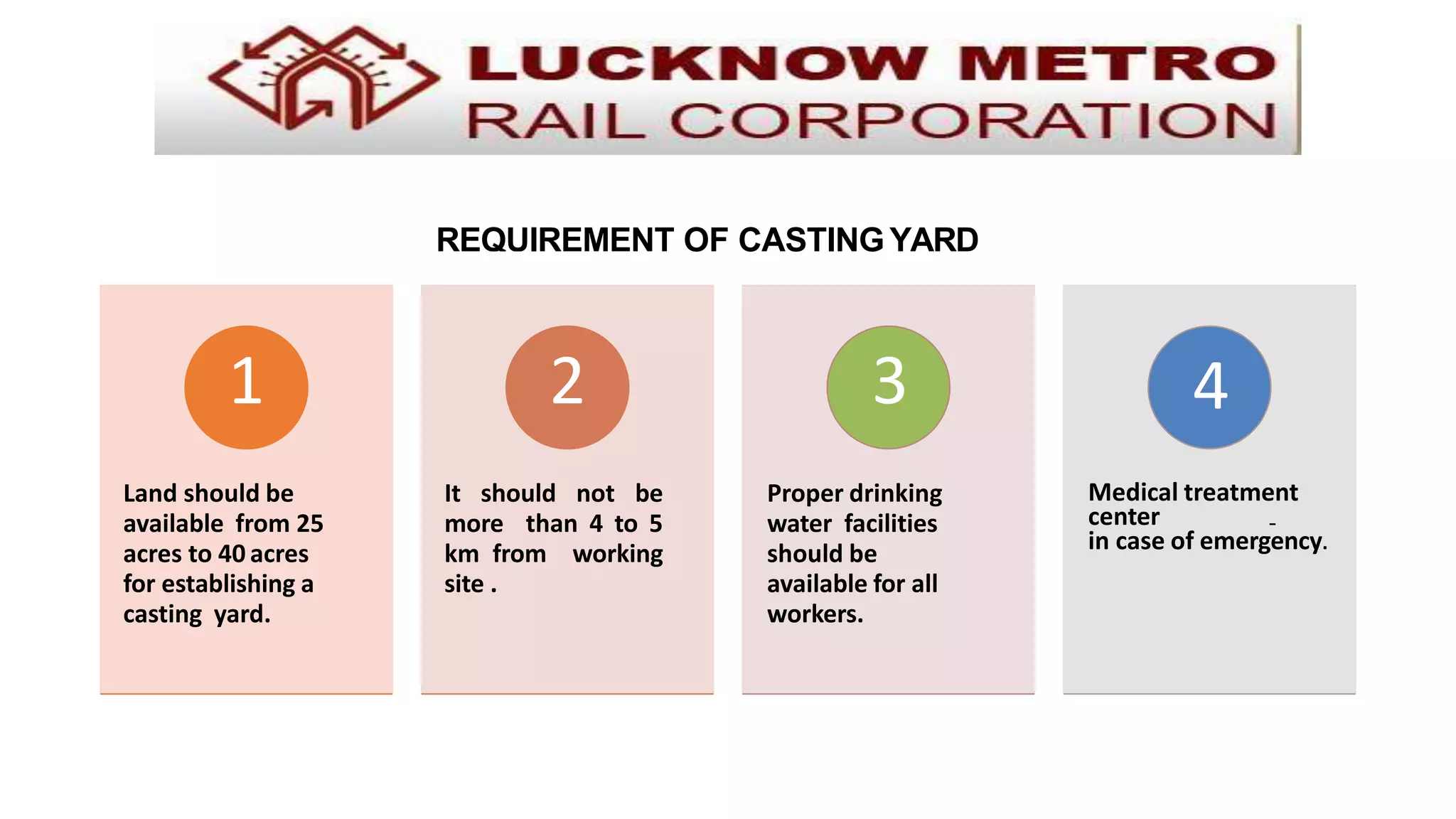

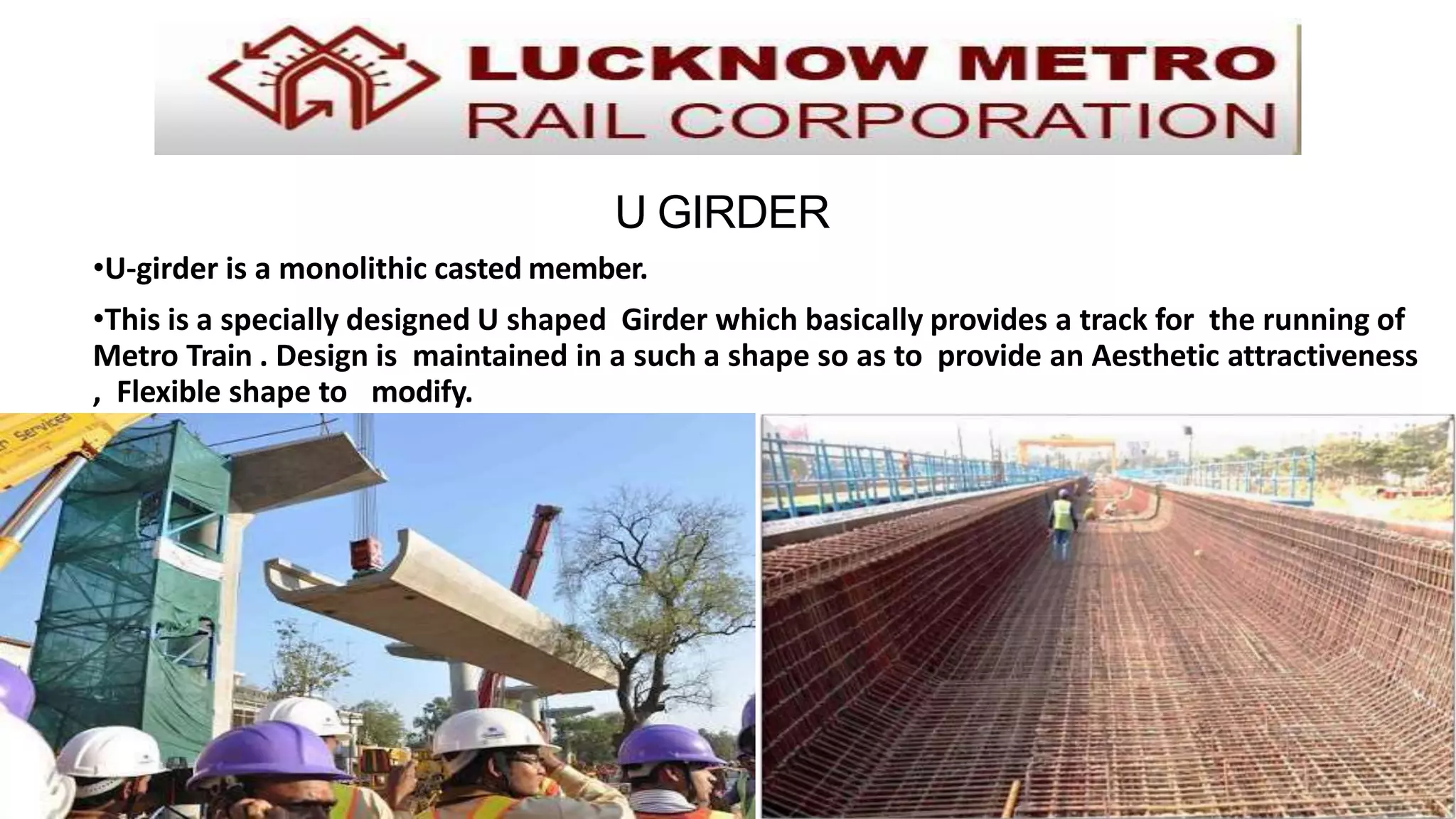

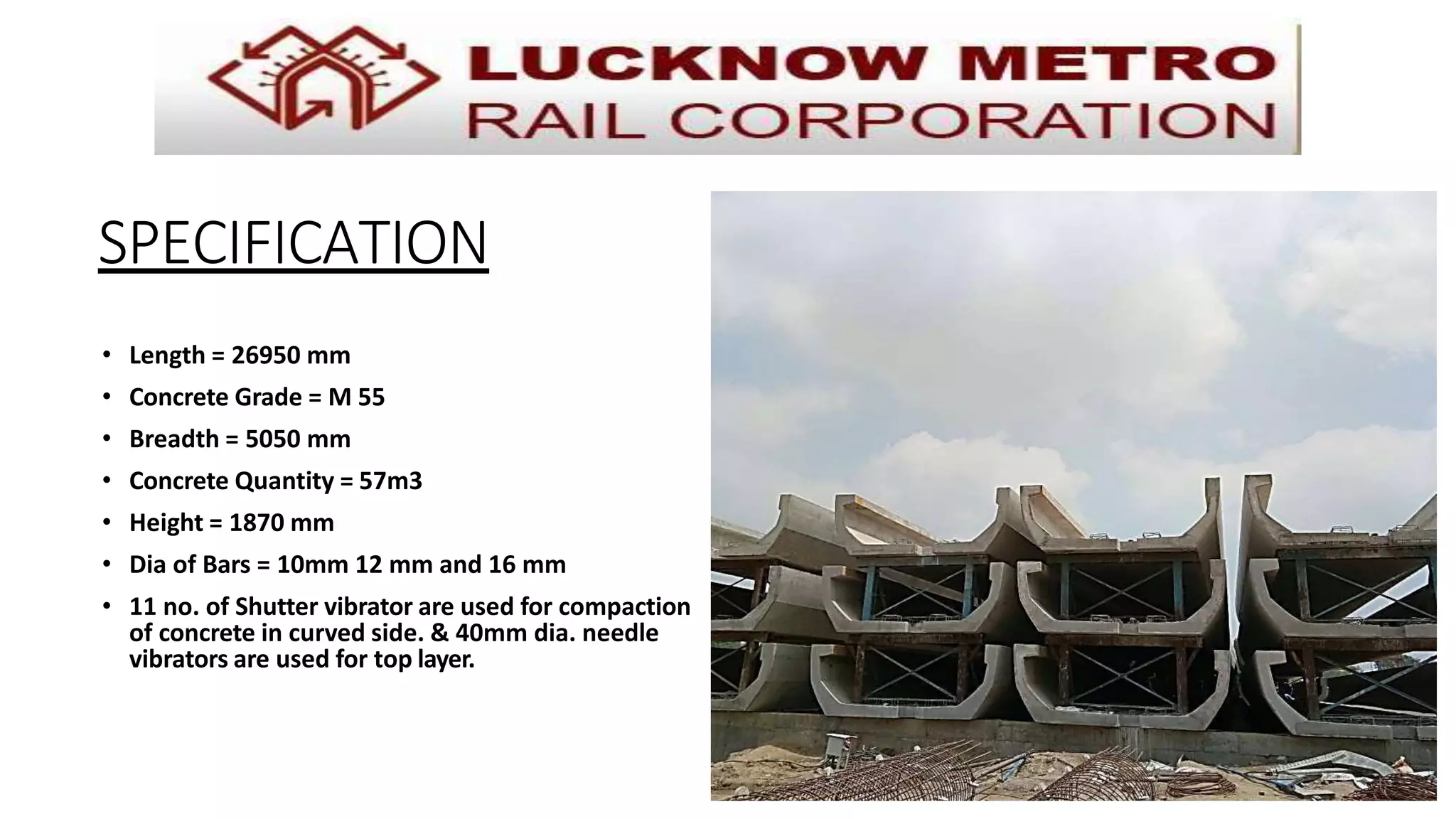

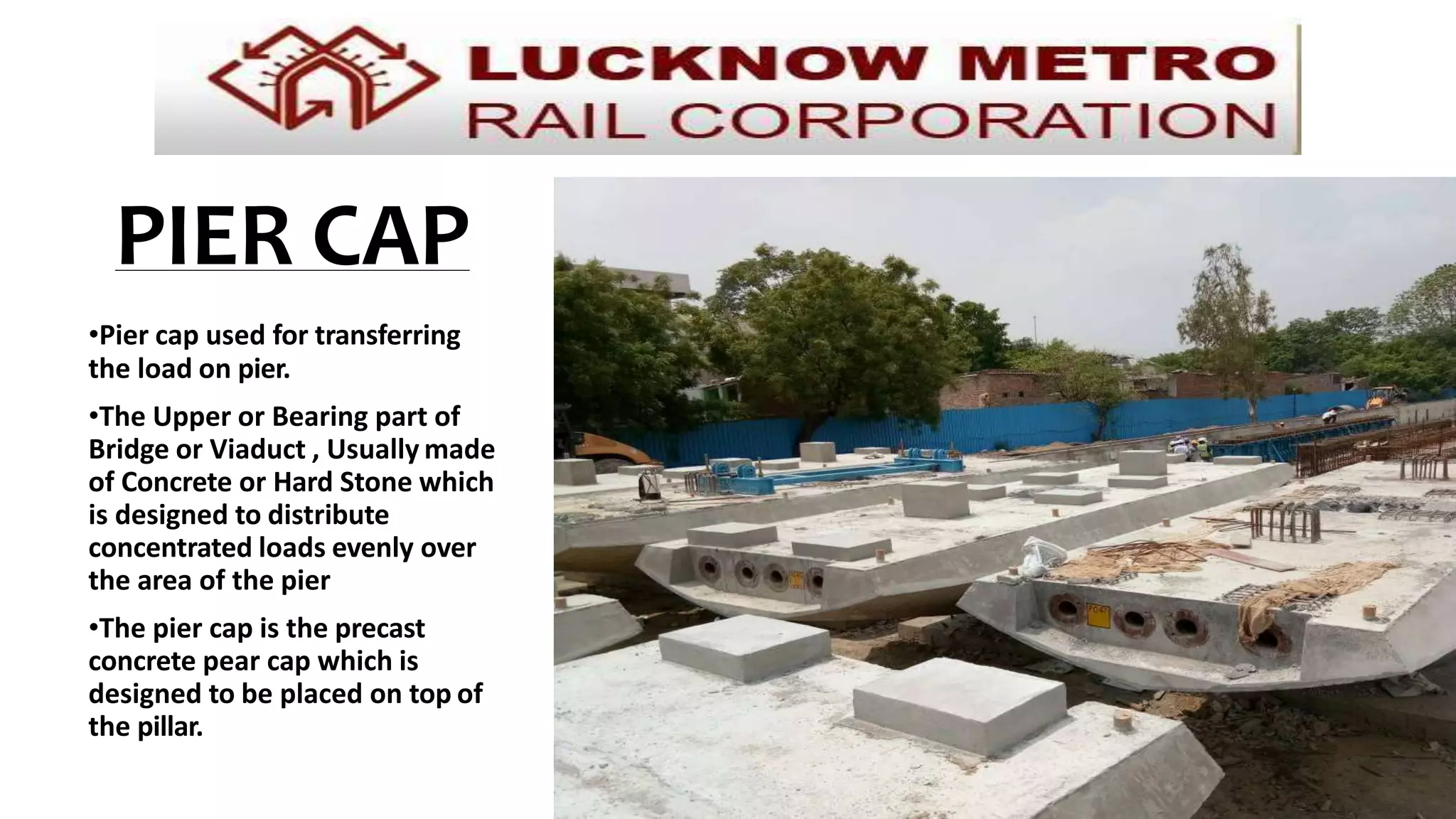

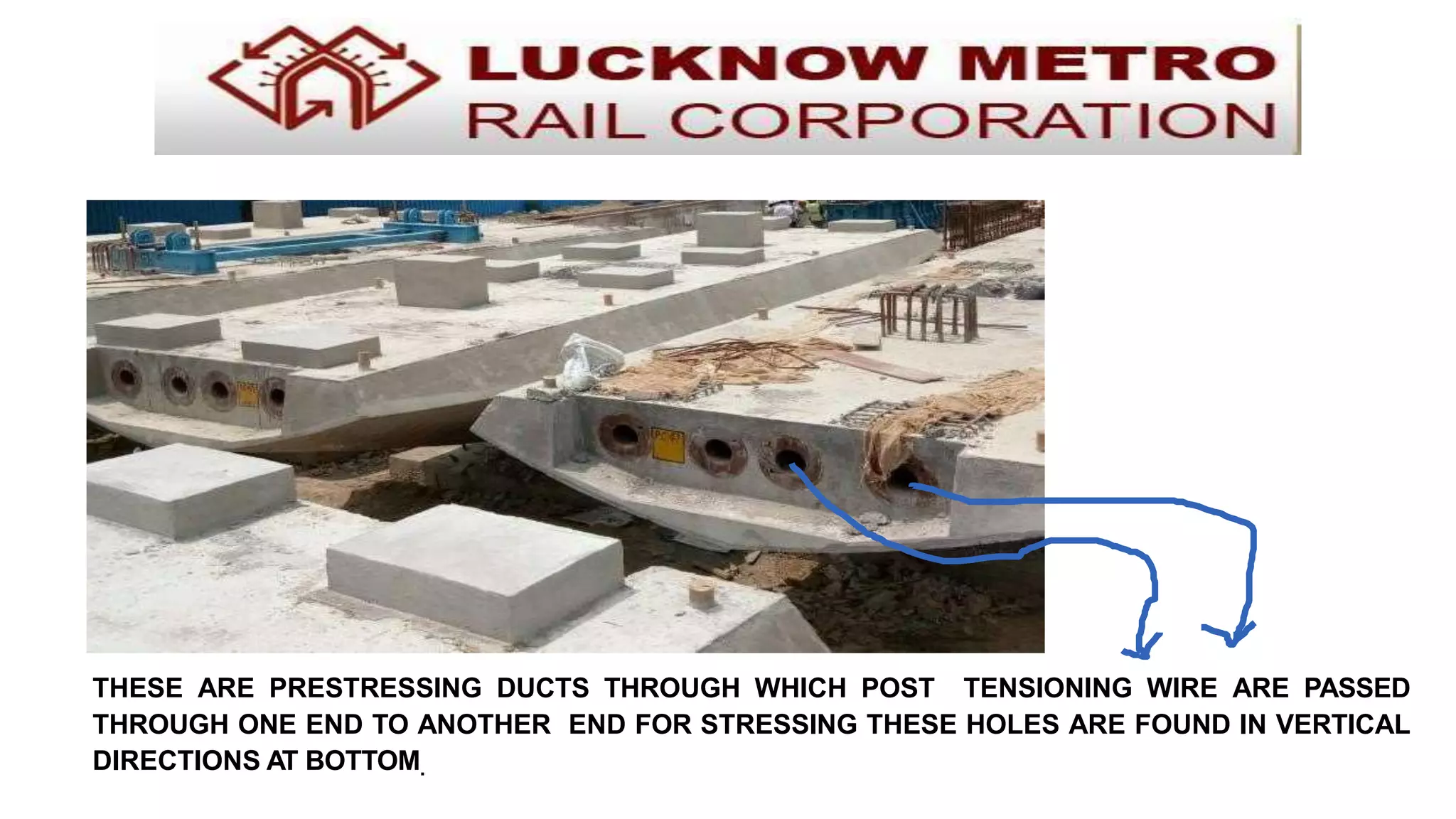

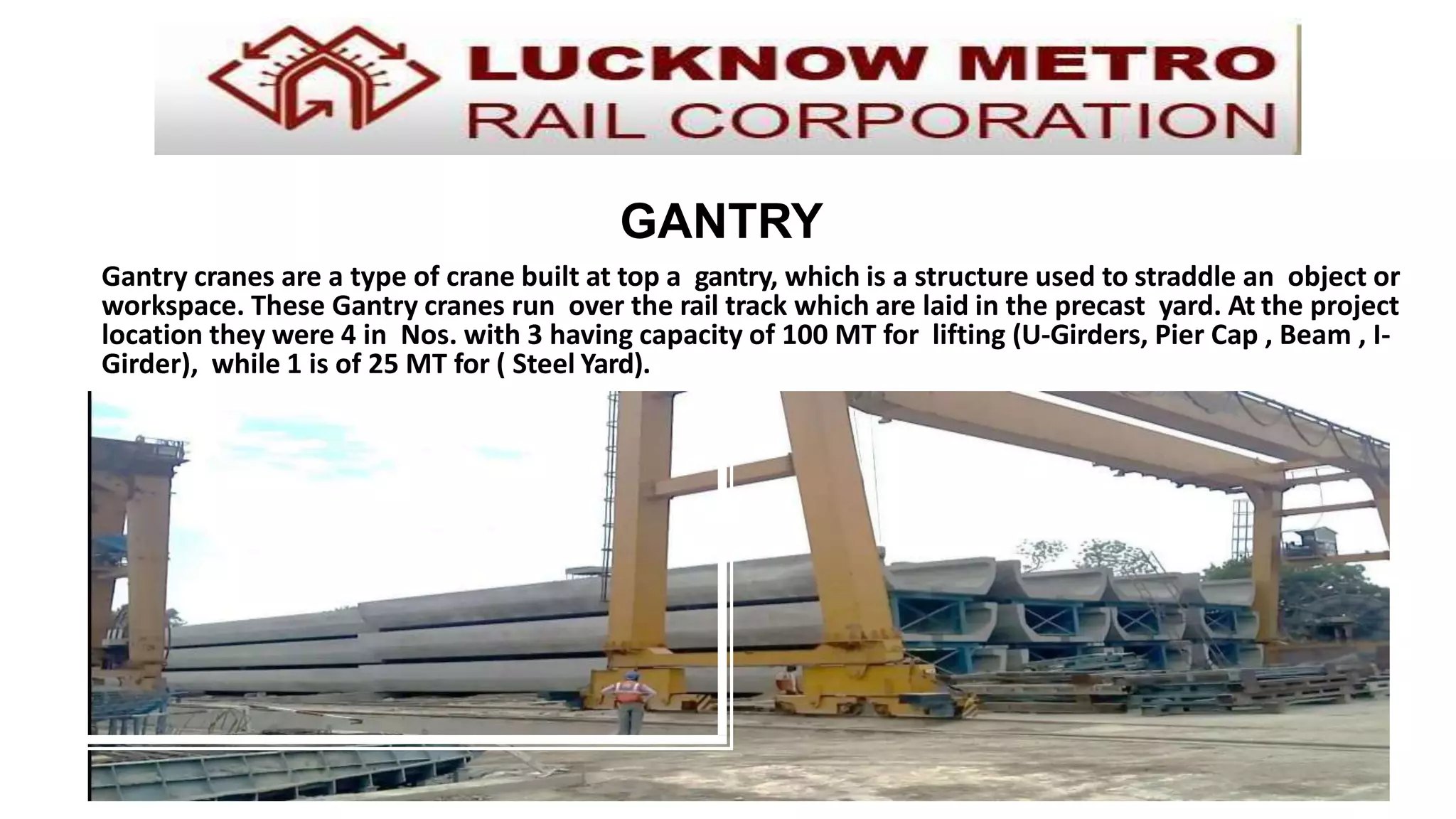

The Lucknow Metro is an under-construction rapid transit system in Lucknow, Uttar Pradesh, aimed at providing speedy mass transport to reduce traffic congestion. The project, managed by Lucknow Metro Rail Corporation, consists of two corridors and is expected to cost ₹12,500 crore, with the first phase operational by 2018. It includes eight elevated stations and various construction details such as U-girders, I-girders, and batching plants necessary for concrete production.