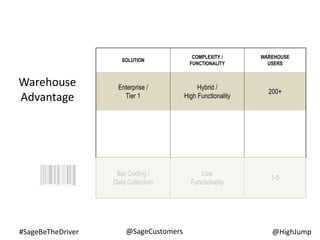

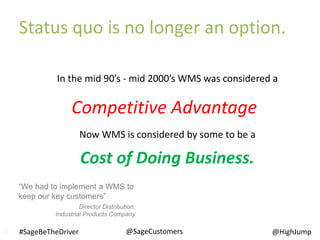

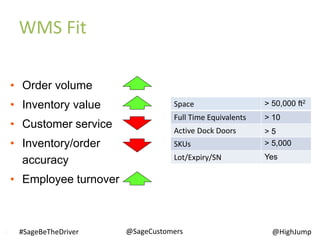

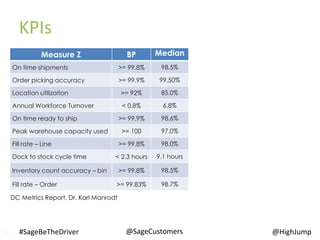

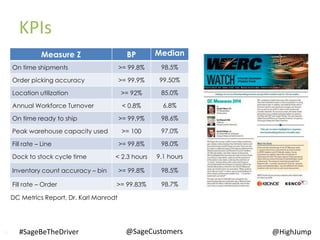

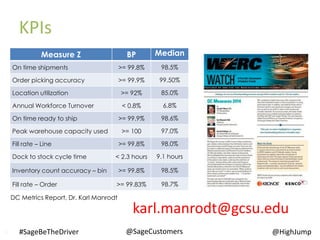

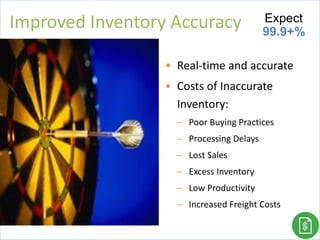

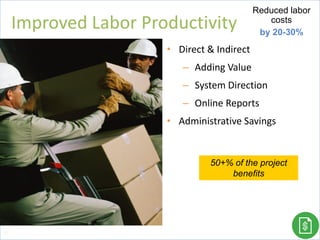

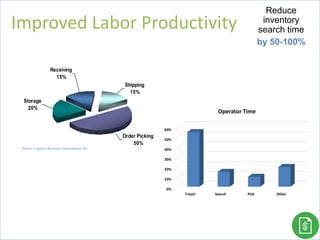

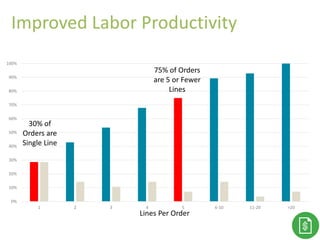

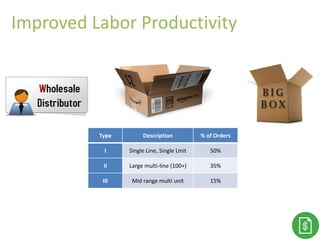

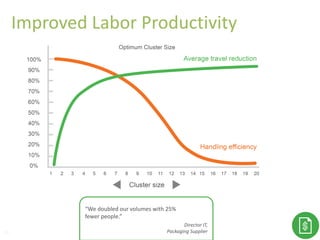

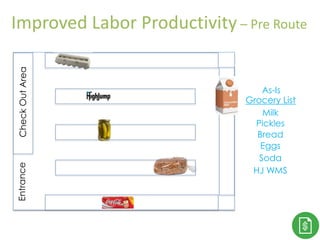

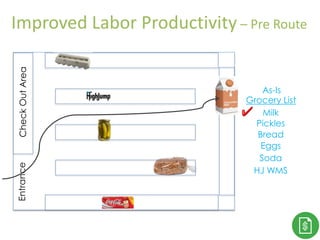

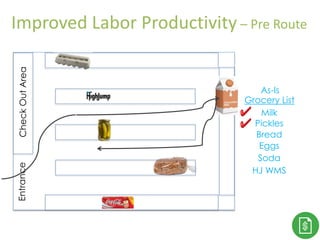

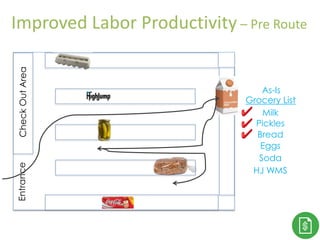

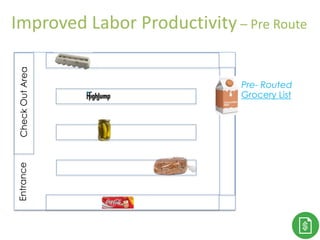

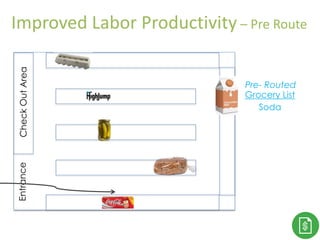

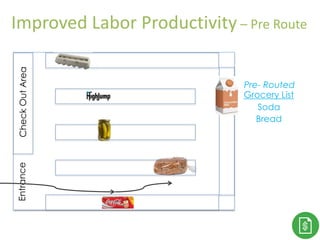

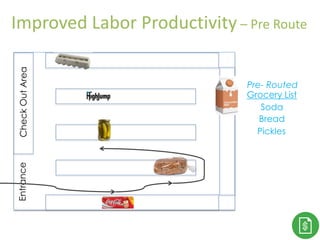

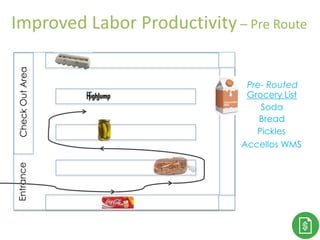

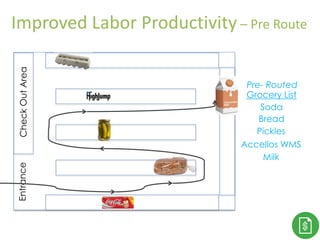

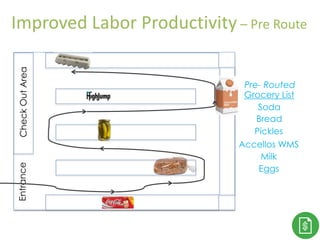

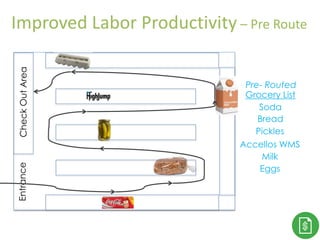

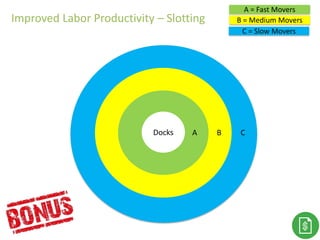

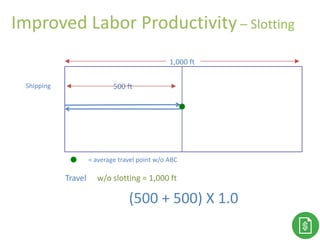

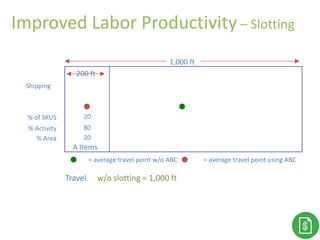

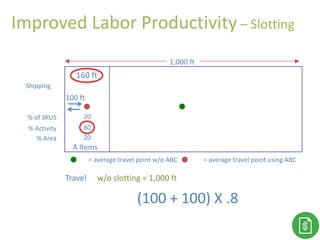

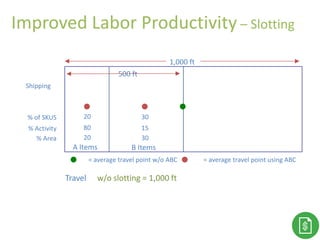

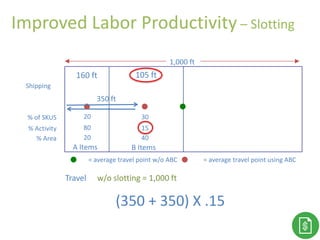

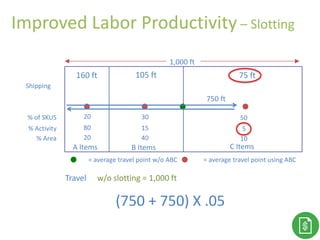

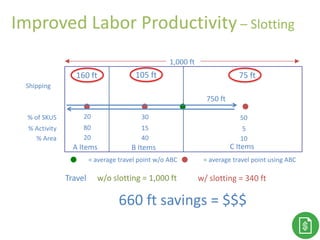

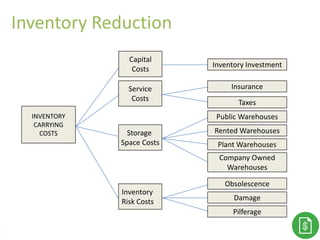

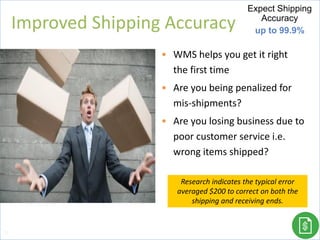

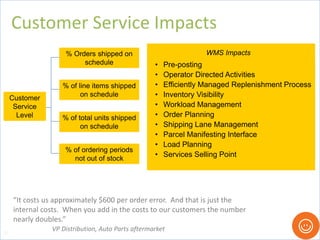

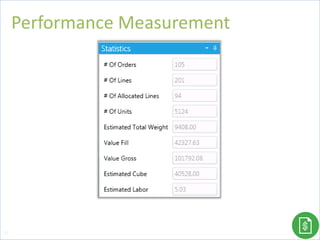

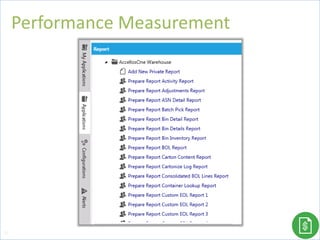

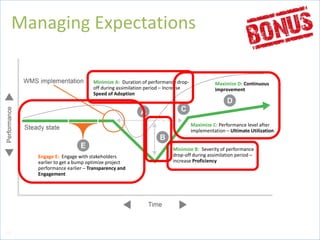

The webinar focuses on enhancing warehouse management systems (WMS) with insights on efficiency, effectiveness, and productivity improvements. Key performance indicators (KPIs) are discussed, highlighting the importance of accurate inventory, order accuracy, and labor productivity in achieving a competitive advantage. Various strategies, such as slotting and pre-routing, are presented to optimize warehouse operations and improve customer service.