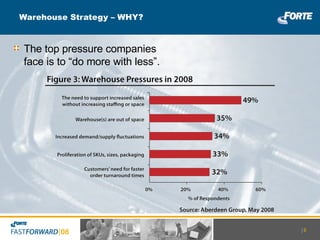

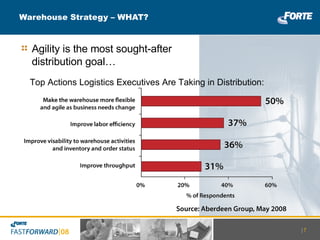

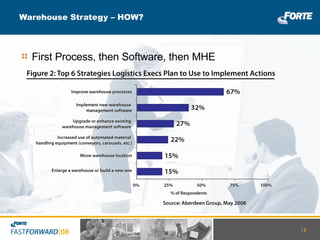

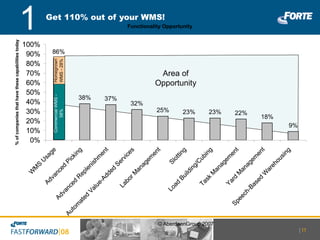

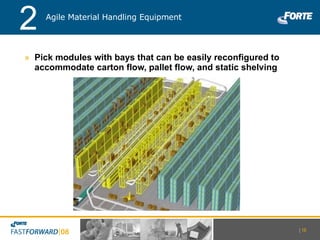

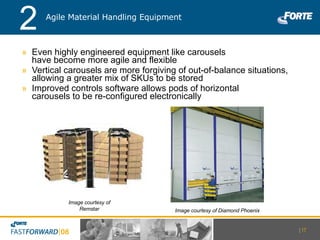

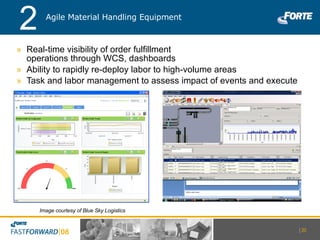

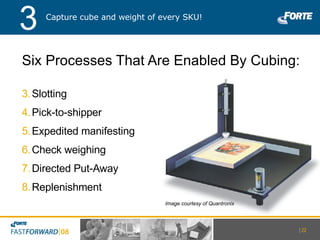

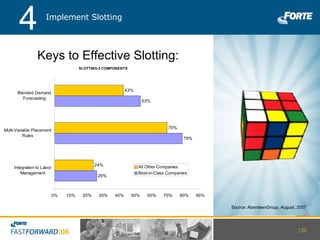

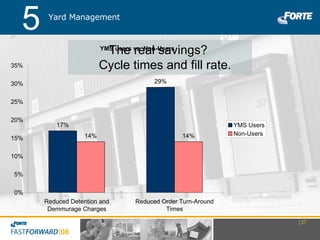

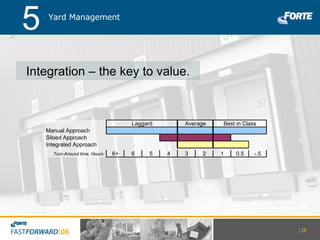

The document discusses five ways to drive efficiency in warehouse operations through increased agility. It recommends maximizing the capabilities of warehouse management systems, using agile material handling equipment that can be easily reconfigured, capturing cube and weight data for all stock keeping units, implementing slotting to optimize storage locations, and effective yard management through integration and focus on cycle times and fill rates. The overall goal is for distribution centers to adopt flexible processes and technologies that allow them to remain agile and adapt to changing business needs.

![Speech-based warehousing – not just for picking anymore Multi-modal devices allow for broader process application Image courtesy of Voxware Agile Material Handling Equipment 2 “ The voice system is almost as fast [as our carousel system], but, dollar-for-dollar, it's the best value for the type of picking that we do.” — a Logistics Manager for a large retail distributor |](https://image.slidesharecdn.com/5waystoimprovewarehouse-124161711494-phpapp01/85/5-Ways-To-Improve-Warehouse-21-320.jpg)

![Thank You! Drew Forte Director Supply Chain Improvement, FORTE [email_address]](https://image.slidesharecdn.com/5waystoimprovewarehouse-124161711494-phpapp01/85/5-Ways-To-Improve-Warehouse-30-320.jpg)