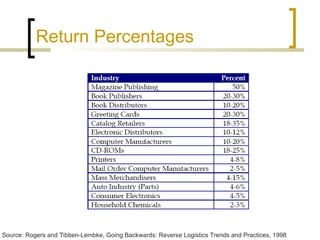

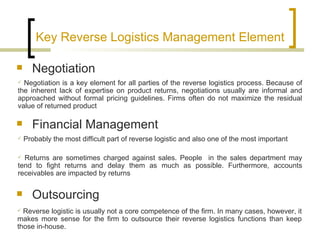

The document discusses reverse logistics, which is defined as the process of planning, implementing, and controlling the efficient flow of raw materials, inventory, finished goods, and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal. Some key aspects of reverse logistics covered include handling returns, recycling and reuse, and hazardous materials disposition. Several industries that deal significantly with reverse logistics such as publishing, electronics, automotive, and retail are examined. Challenges of reverse logistics and key management elements like avoidance, gatekeeping, compacting disposition cycle time, information systems, zero returns, and remanufacturing are also summarized.