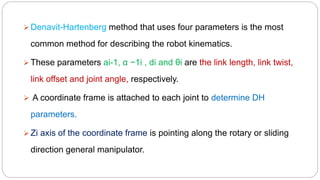

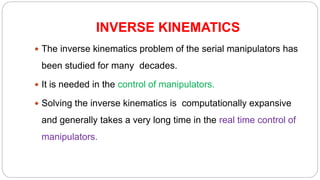

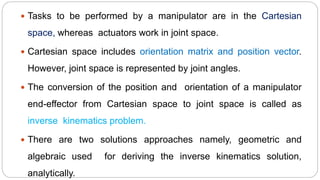

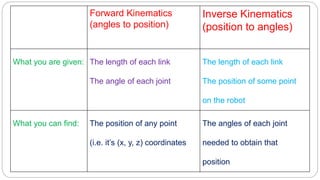

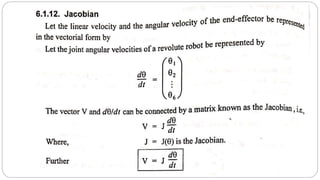

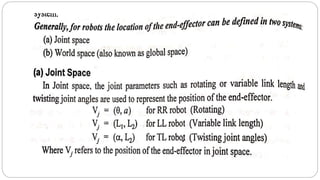

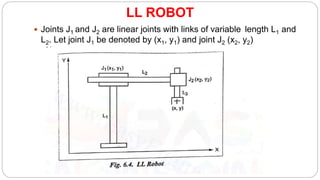

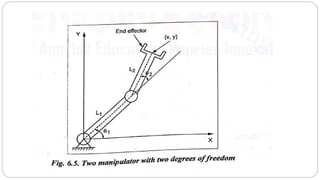

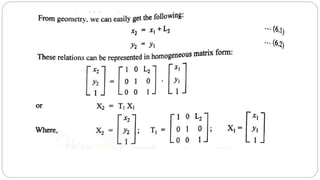

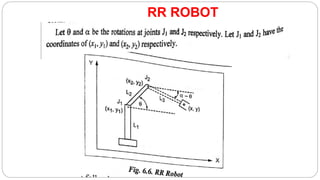

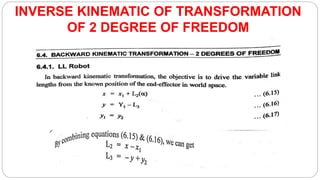

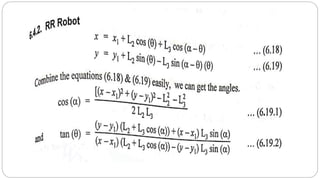

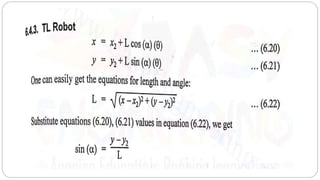

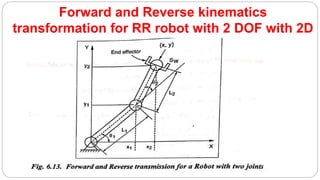

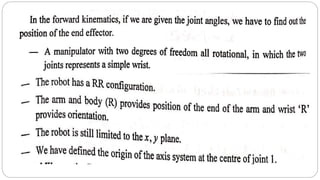

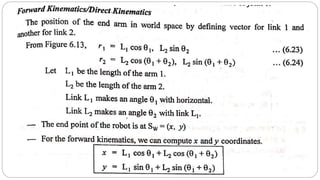

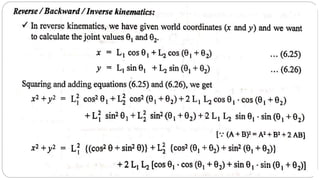

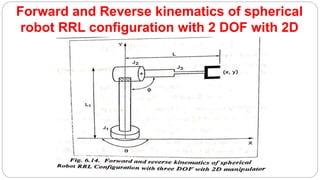

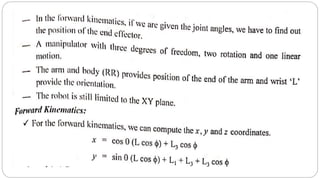

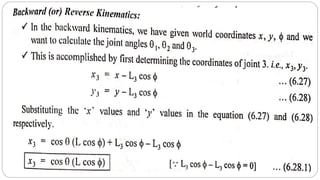

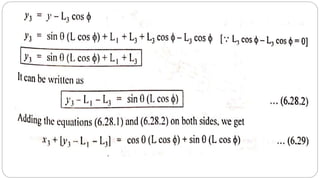

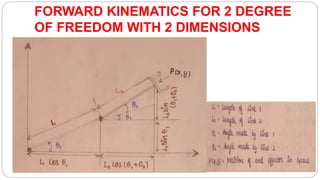

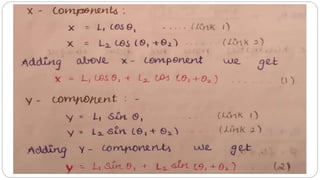

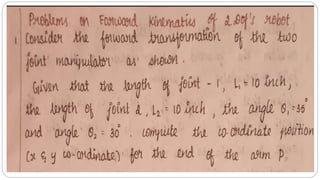

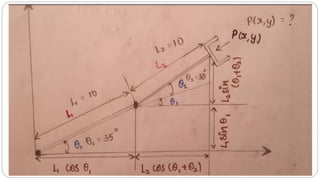

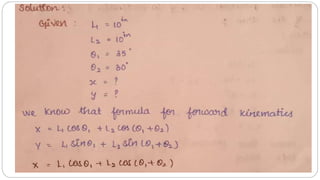

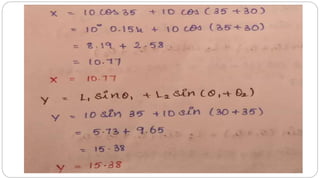

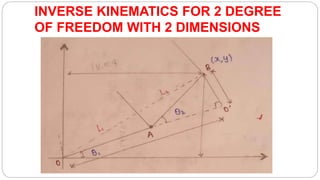

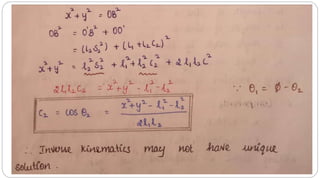

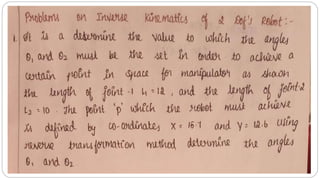

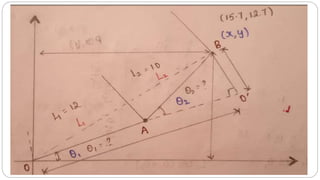

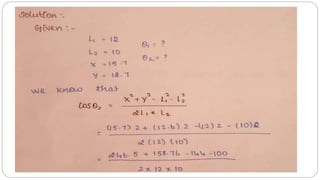

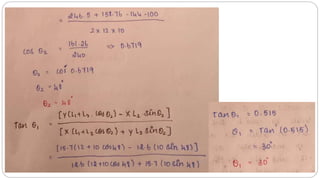

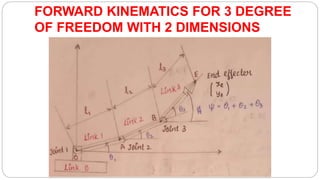

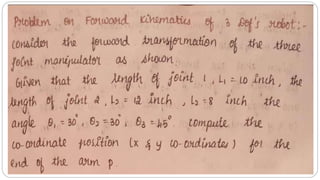

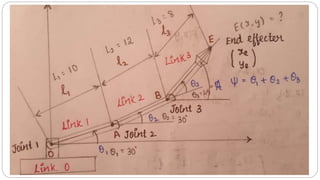

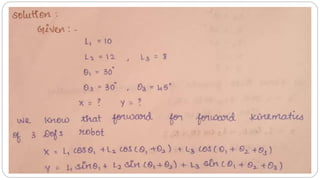

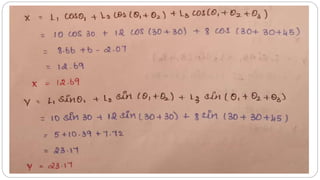

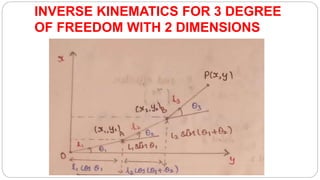

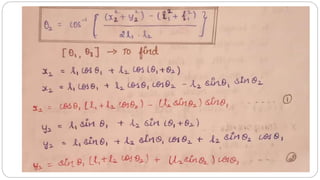

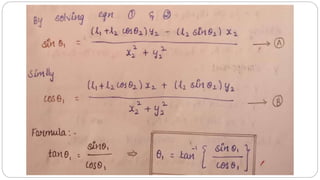

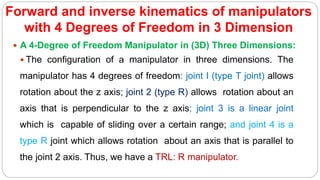

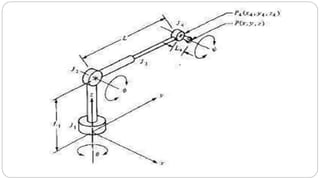

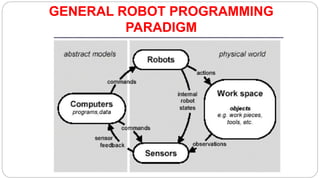

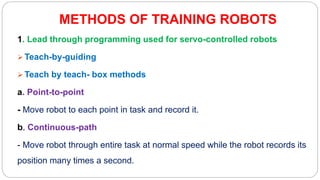

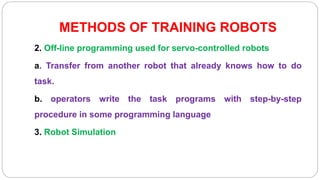

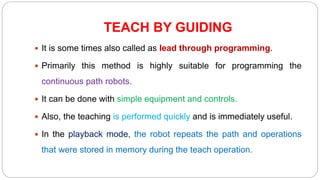

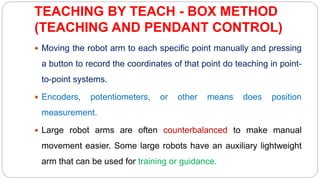

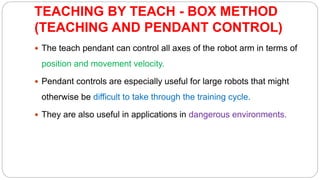

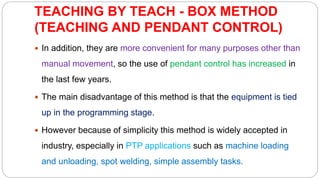

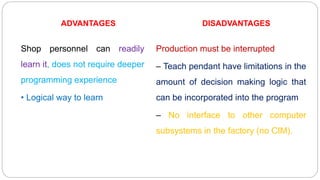

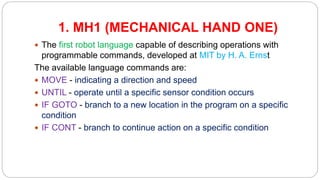

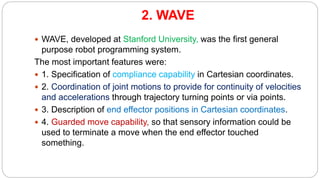

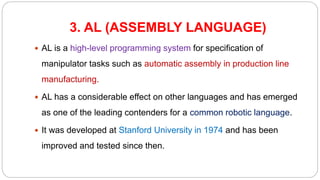

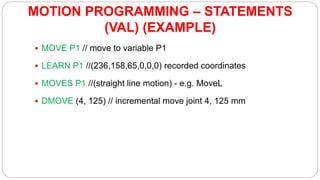

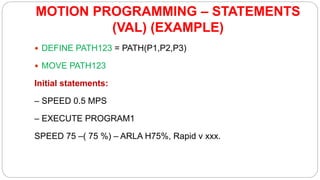

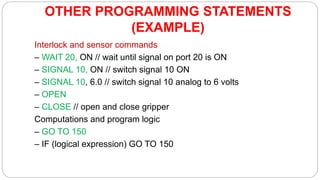

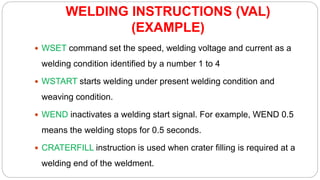

The document covers the topics of robot kinematics and programming, detailing forward and inverse kinematics for manipulators with multiple degrees of freedom, the Denavit-Hartenberg method, and various programming methods such as lead-through and offline programming. It reviews several robotic programming languages, including MH1, Wave, and VAL, highlighting their features, applications, and the evolution of language capabilities in robot control. Additionally, it discusses teaching methods for programming robots and emphasizes the significance of systematic approaches to kinematics in the control and operation of robotic systems.