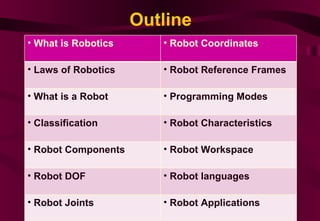

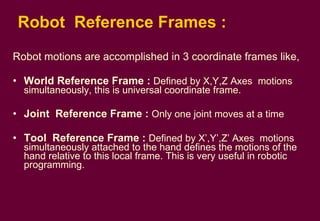

The document provides an introduction to robotics, including definitions of key terms:

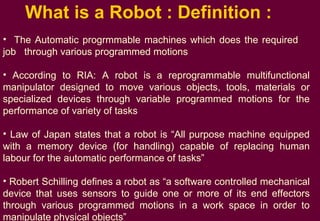

- A robot is an automatically controlled, reprogrammable device designed to perform tasks normally done by humans.

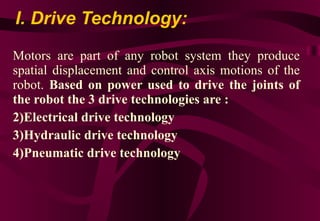

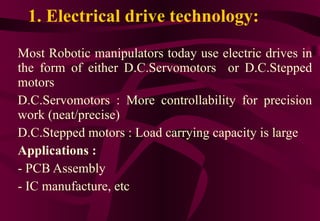

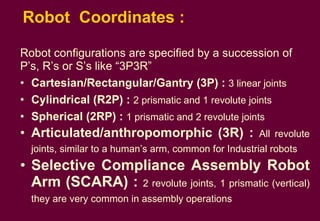

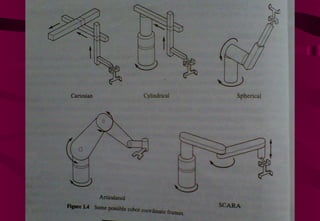

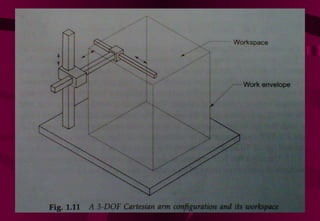

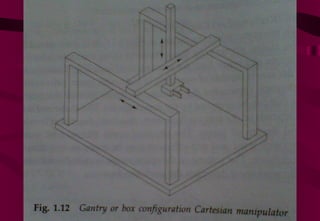

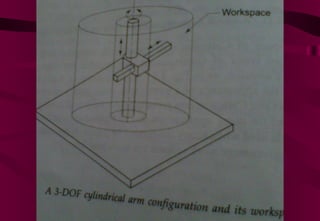

- Robots are classified based on their drive technology, work envelope/coordinate geometry, and motion control methods.

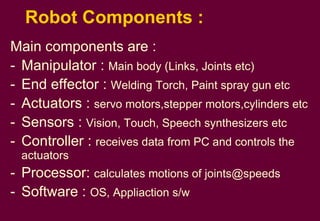

- Robotic systems have components like manipulators, end effectors, actuators, sensors, controllers, and software to allow various applications in manufacturing and other industries.