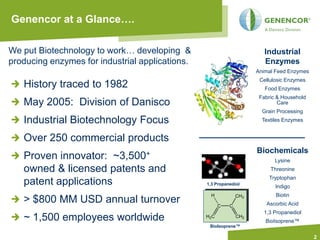

Industrial biotechnology uses enzymes and engineered microorganisms to convert renewable biomass into fuels, power, and chemicals. This process is analogous to petroleum refineries and enables the development of biorefineries. Genencor is a leader in industrial biotechnology and has developed enzymes that enable the conversion of starch and cellulosic feedstocks into biofuels and biochemicals. Genencor's enzymes have helped advance biorefineries from first generation starch-based ethanol to future generations using lignocellulosic biomass as a sustainable feedstock.