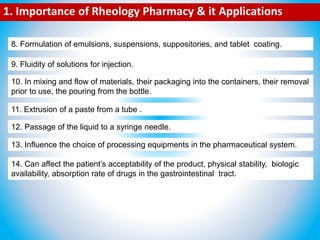

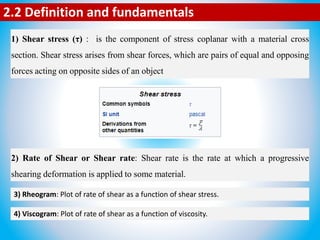

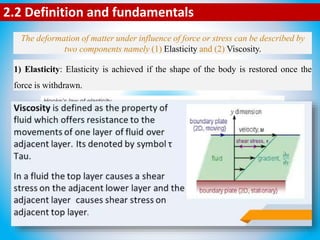

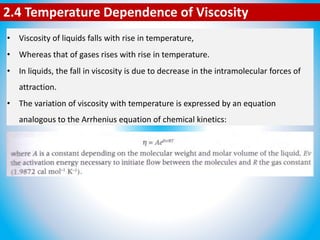

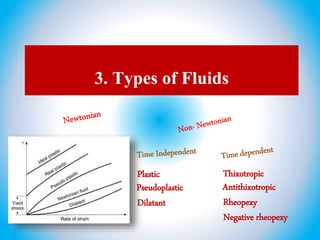

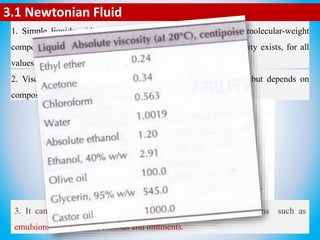

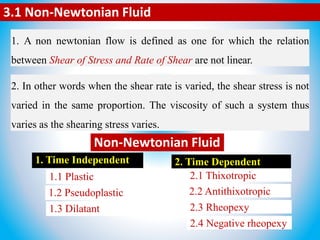

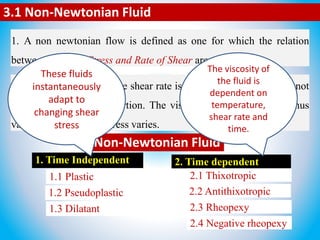

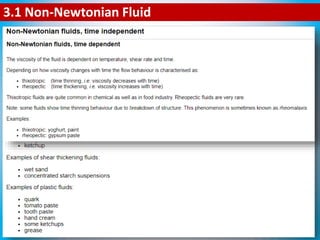

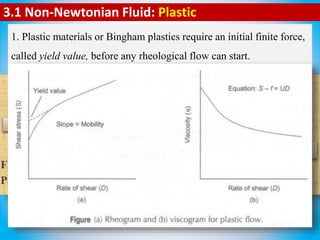

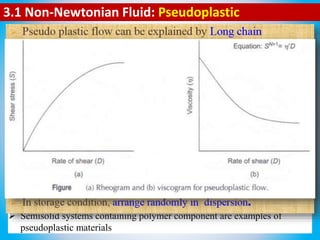

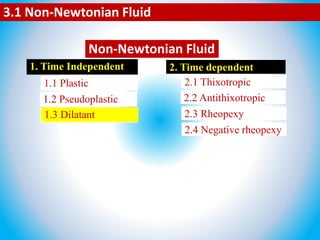

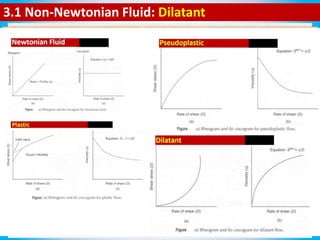

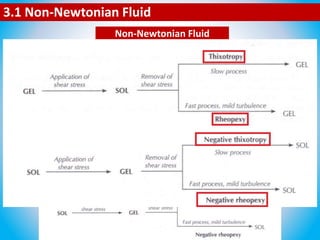

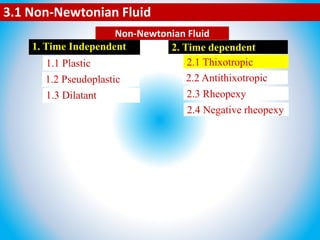

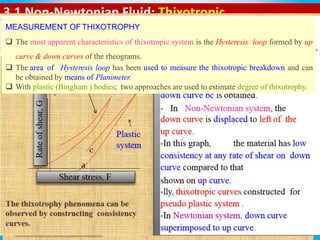

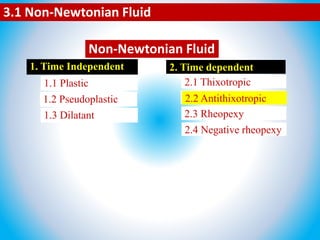

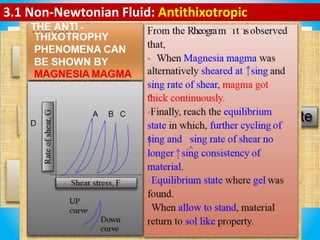

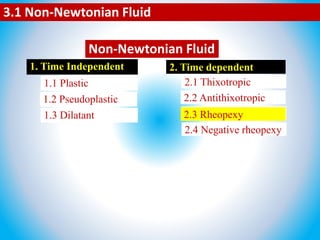

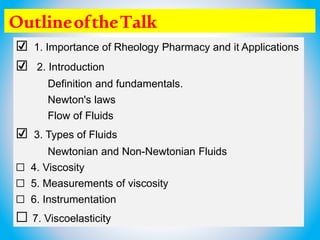

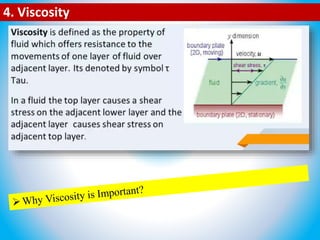

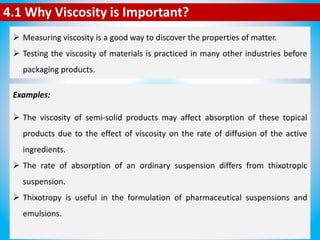

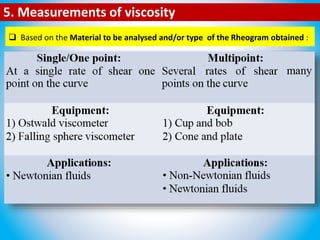

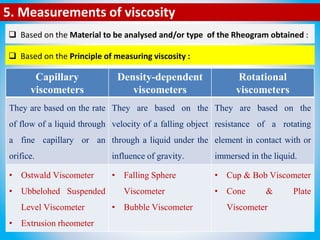

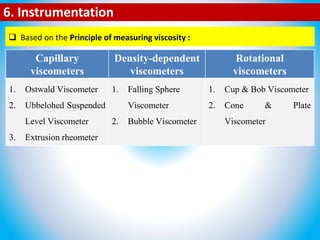

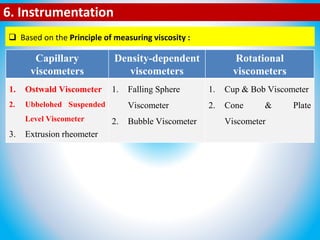

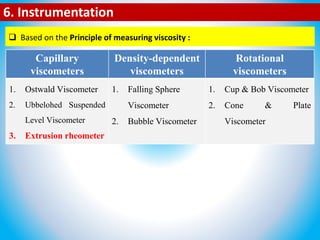

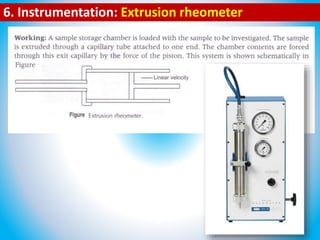

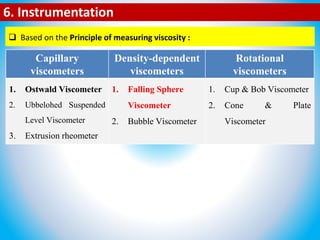

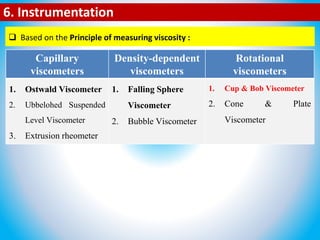

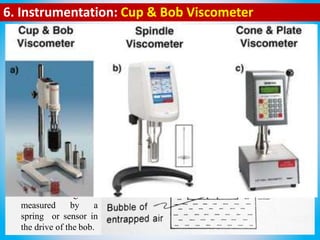

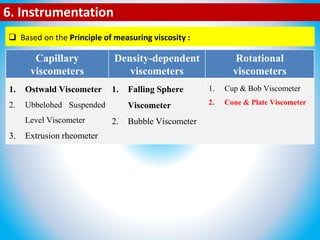

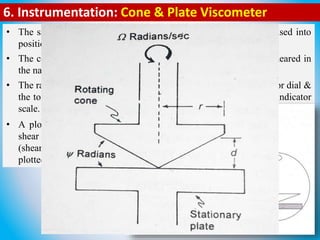

This document discusses an introduction to rheology and its importance in pharmacy. It begins by outlining the topics to be covered, which include the importance of rheology in pharmacy applications, definitions and fundamentals, types of fluids, viscosity, measurements of viscosity, instrumentation, and viscoelasticity. The first section defines rheology and describes its importance in areas like manufacturing dosage forms, handling drugs for administration, topical applications, and more. The introduction provides definitions of key terms like shear stress and rate of shear. It also describes Newton's laws of viscous flow. The document goes on to classify fluids as Newtonian or non-Newtonian and describes different types of non-Newtonian fluids.