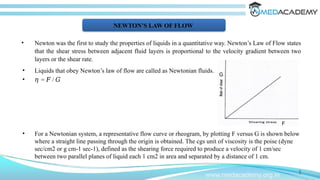

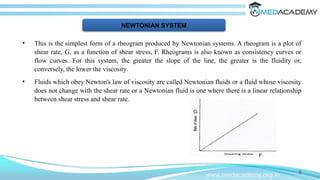

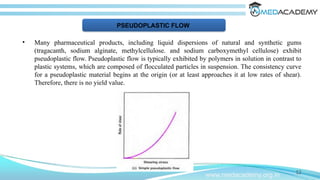

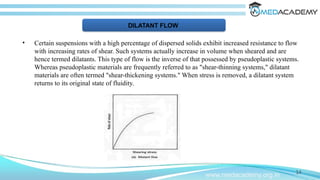

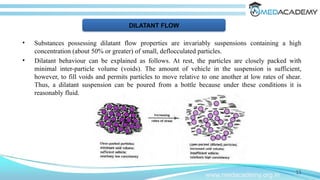

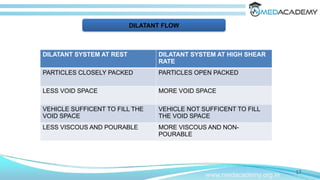

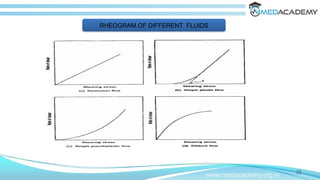

Rheology is the science of flow and deformation of matter, focusing on how materials behave under stress. It distinguishes between Newtonian fluids, which have a consistent viscosity regardless of shear rate, and non-Newtonian fluids, which show varying viscosity under different shear conditions, including plastic, pseudoplastic, and dilatant behavior. These properties are crucial in pharmaceuticals for manufacturing and administering dosage forms, affecting processes like mixing and dispensing.