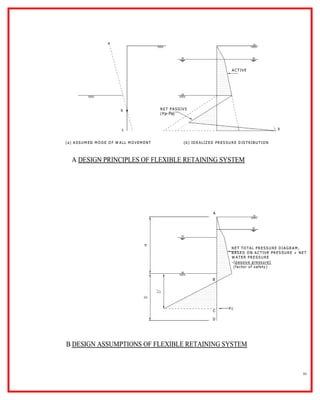

The document outlines the construction and design principles of steel sheet piling, emphasizing its lightweight, reusable, and durable characteristics. It describes the installation process, various anchoring methods, and how to calculate the lateral and passive earth pressures relevant to the design. Additionally, it provides examples of structural analysis necessary for determining the sizes and strengths of sheet piles and associated components like tie rods and soldier beams.

![43

embedded depth can be determined by summarizing horizontal earth pressures and moments about

the anchor.

Fx = 0 [1]

Mo = 0 [2]

the lateral earth pressure is a function of embedded depth. Both equations are highly nonlinear. A

trial and error method has to be used to determine the root.

r structural design, the sheet pile needs to be able to withstand maximum moment and shear from

lateral pressure. A structural analysis needs to be done to determine maximum moment and

shear.](https://image.slidesharecdn.com/retainingwall-150806080725-lva1-app6892/85/Retaining-wall-Scant-Piles-43-320.jpg)

![48

Example 3. Design anchored sheet pile in cohesionless soil.

Depth of excavation, h = 10 ft

Unit weight of soil, = 115 lb/ft3

Internal friction angle, = 30 degree

Allowable design stress of sheet pile = 32 ksi

Yield strength of soldier beam, Fy = 36 ksi

Location of tie rod at 2 ft below ground surface, spacing, s = 12 ft

Requirement: Design length of an anchored sheet pile, select sheet pile section, and design tie rod

Solution:

Design length of sheet pile:

Calculate lateral earth pressure coefficients:

Ka = tan (45-/2) = 0.333

Kp = tan (45-/2) = 3

The lateral earth pressure at bottom of excavation is

pa = Ka h = 0.333*115*10 = 383.33 psf

The active lateral force above excavation

Ha1 = pa*h/2 = 383.33*10/2 = 1917 lb/ft

The depth a = pa / (Kp-Ka) = 383.3 / [115*(3-0.333)] =1.25 ft

The corresponding lateral force

Ha2 = pa*a/2 = 383.33*1.25/2 = 238.6 lb/ft

Assume Y = 2.85 ft

HCEF = (Kp-Ka) Y2

/3 = 115*(3-0.333)*2.852

/3 = 830.3 lb/ft

y1 = (2h/3-b) = (2*10/3-2)=4.67 ft

y2 = (h+a/3-b) = (10+1.25/3-2)=8.42 ft

y3 = (h+a+2Y/3) = (10+1.25+2*2.85/3) = 13.15 ft](https://image.slidesharecdn.com/retainingwall-150806080725-lva1-app6892/85/Retaining-wall-Scant-Piles-48-320.jpg)