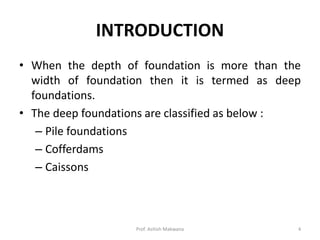

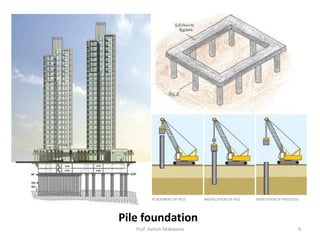

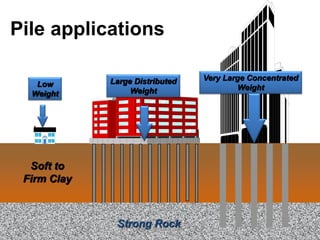

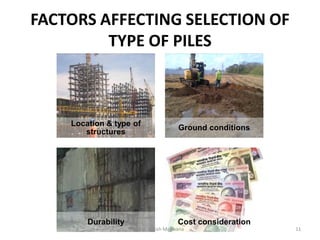

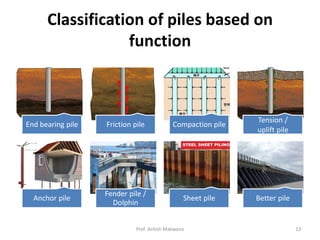

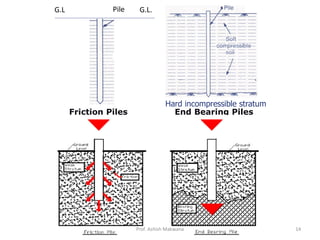

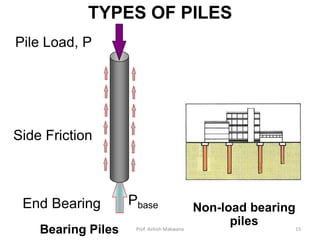

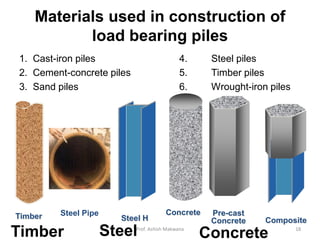

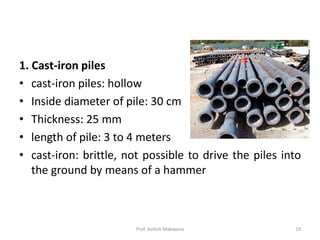

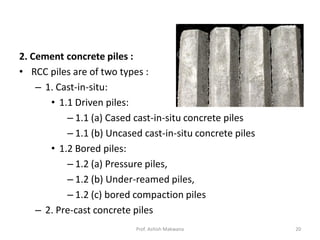

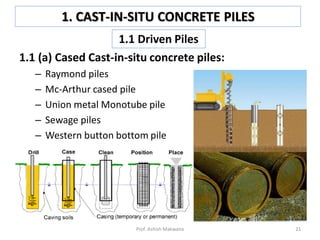

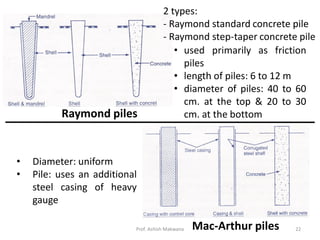

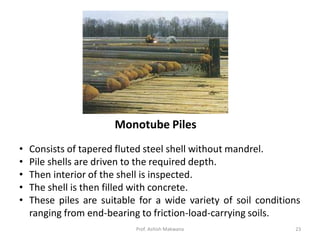

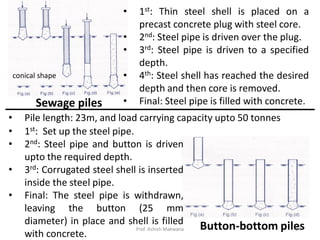

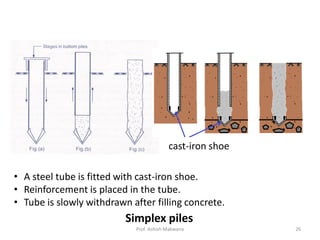

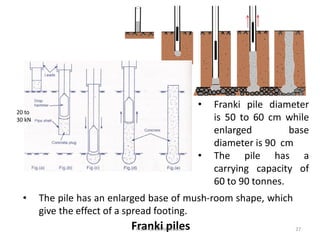

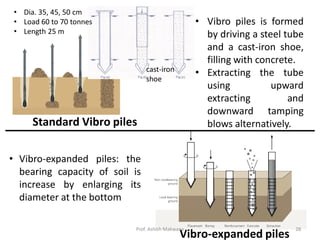

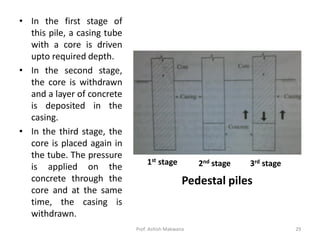

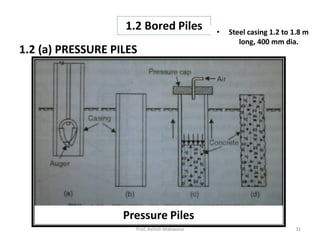

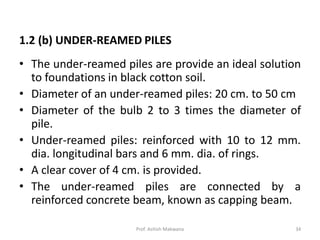

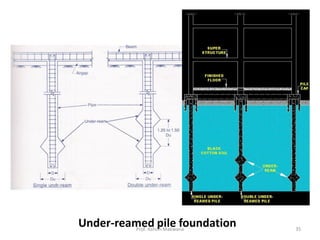

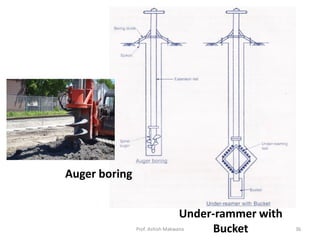

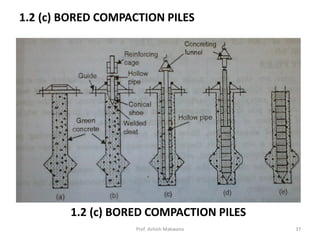

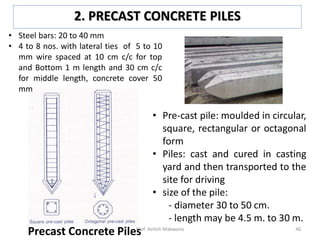

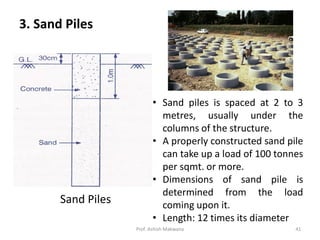

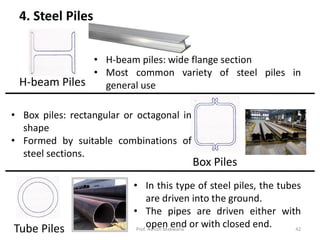

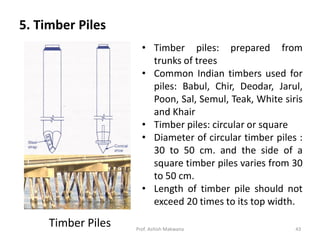

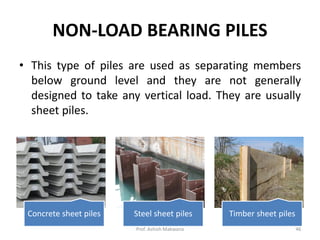

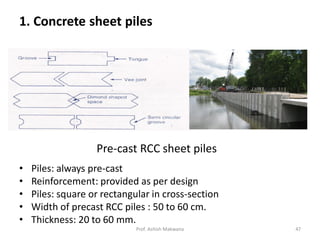

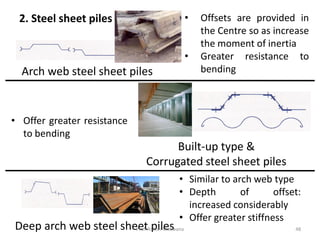

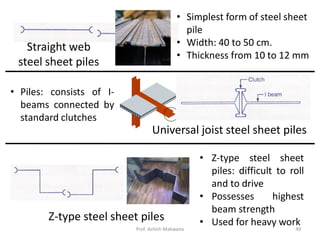

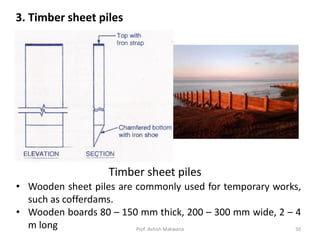

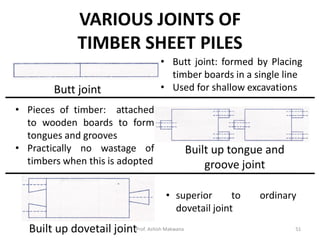

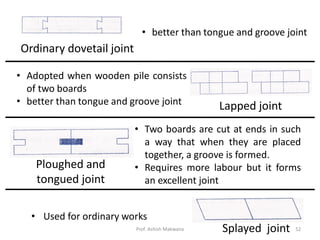

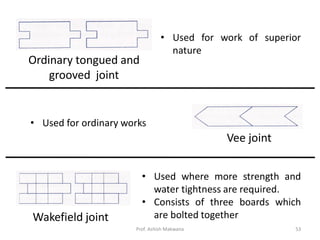

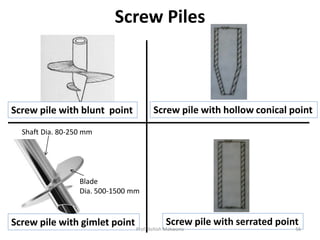

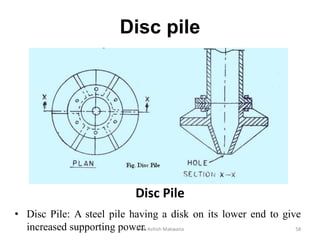

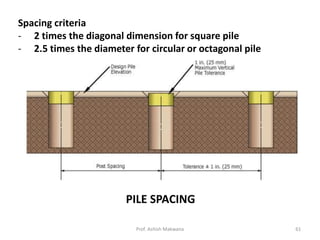

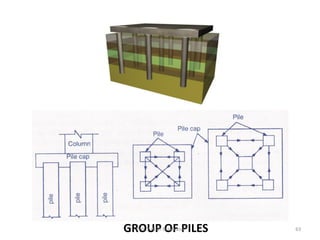

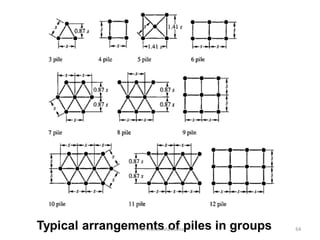

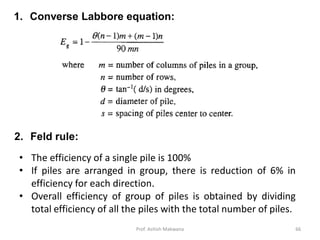

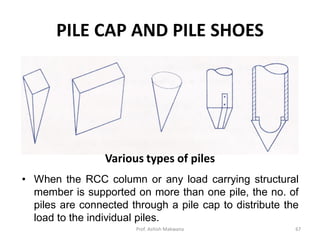

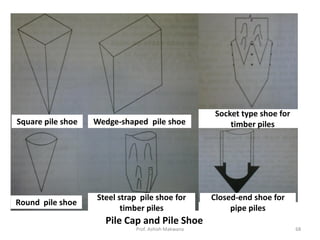

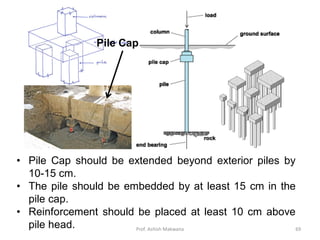

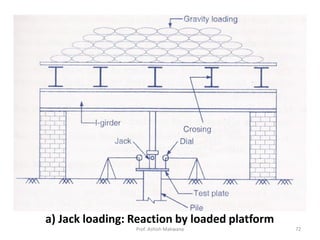

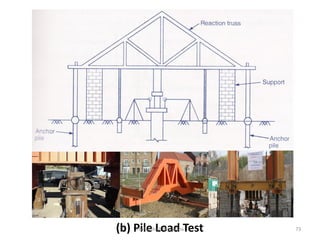

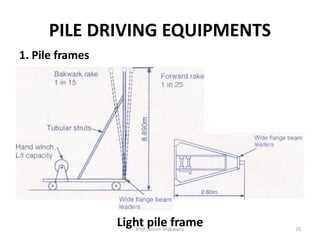

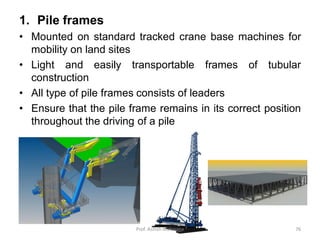

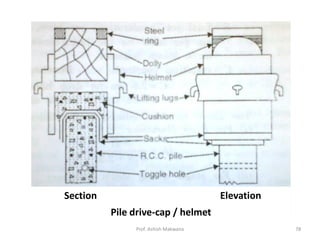

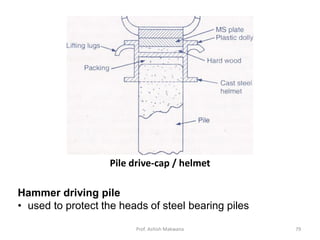

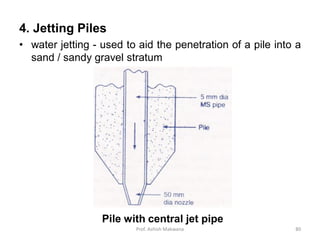

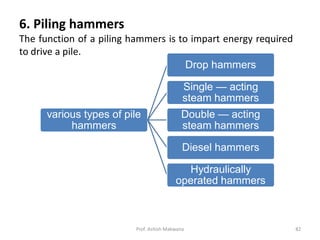

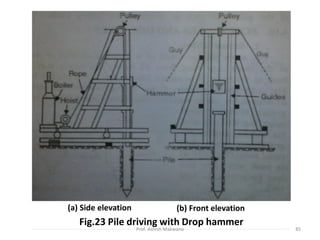

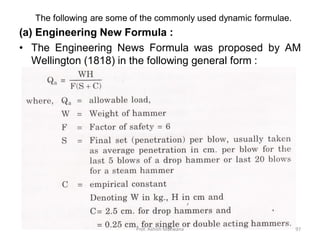

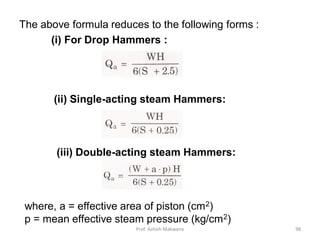

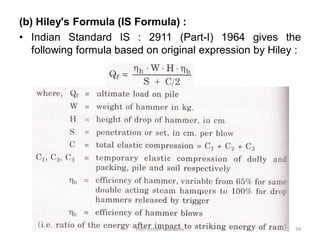

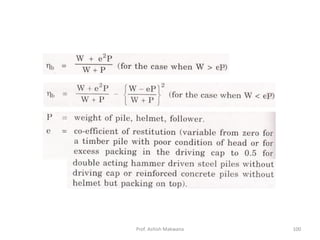

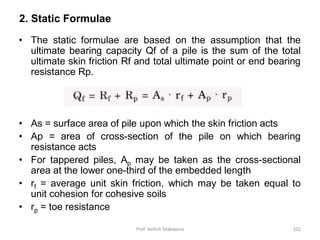

The document is a detailed presentation on pile foundations, discussing their types, uses, and factors affecting their selection. It covers load tests, installation techniques, and materials used in pile construction, including various forms of concrete, steel, and timber piles. The document also explores specific types of piles and their construction methods, emphasizing their importance in civil engineering for deep foundations.