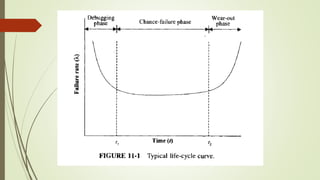

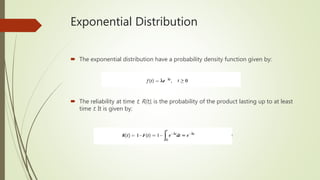

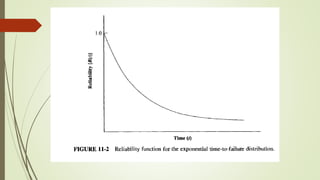

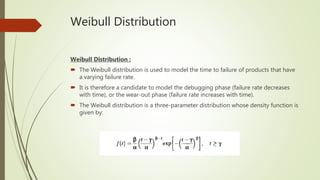

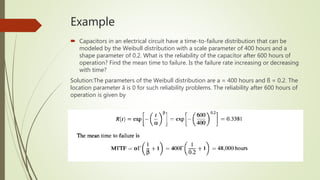

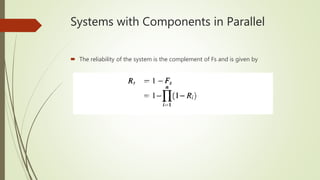

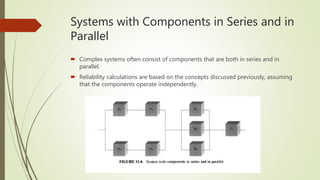

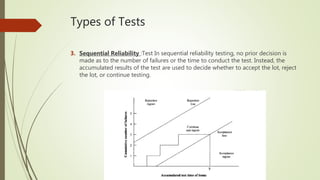

The document summarizes Rahul Singh's seminar presentation on reliability. It defines reliability as the ability of a product to perform as expected over time, with a probability between 0 and 1 under specified conditions. There are two types of failures: functional and reliability. Reliability is measured through failure rate and other metrics. Products go through debugging, chance failure, and wear-out phases as shown in the bathtub curve. Exponential and Weibull distributions model failure rates. System reliability depends on components arranged in series, parallel or both. Life testing plans include failure-terminated, time-terminated and sequential tests.