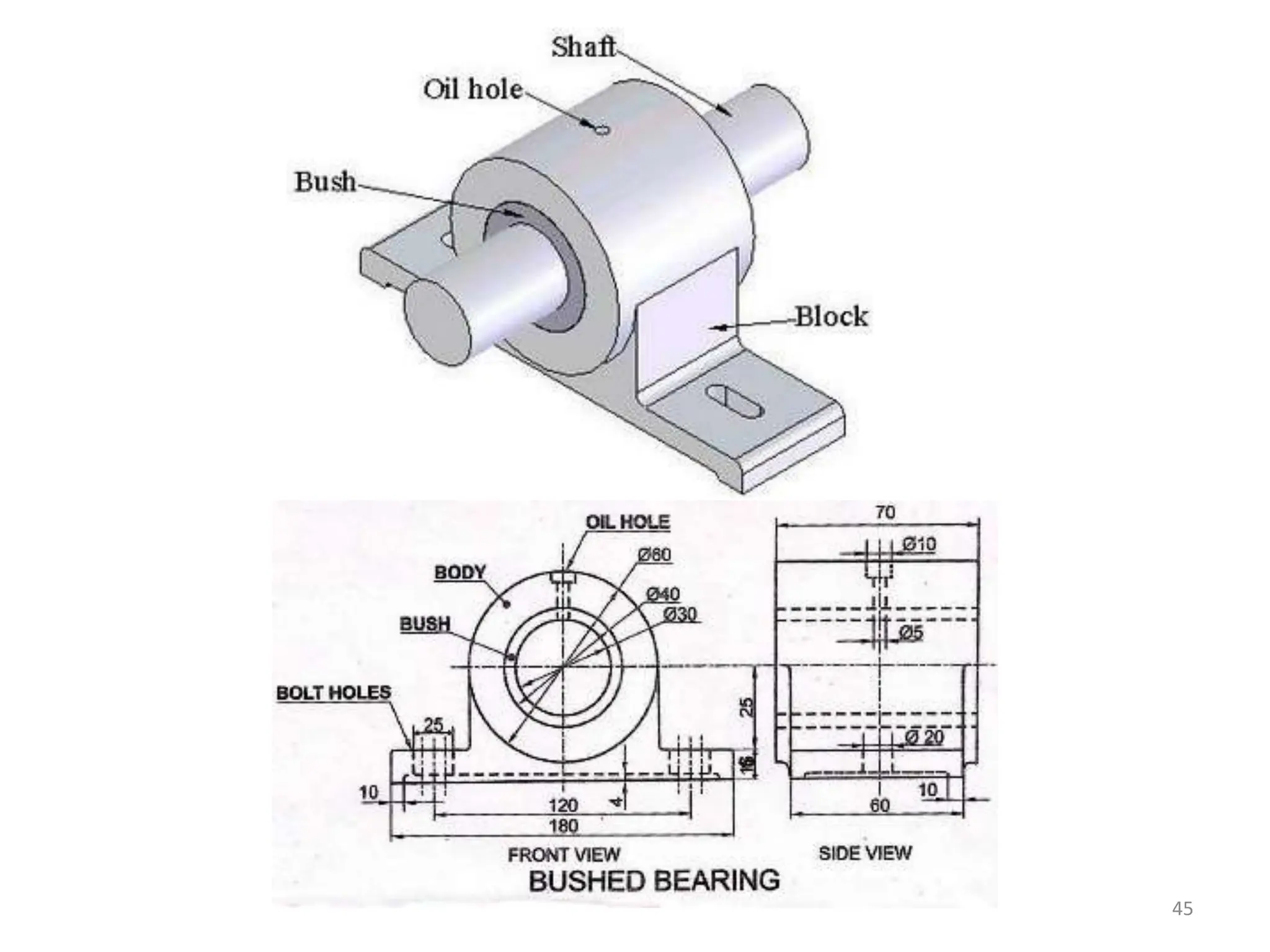

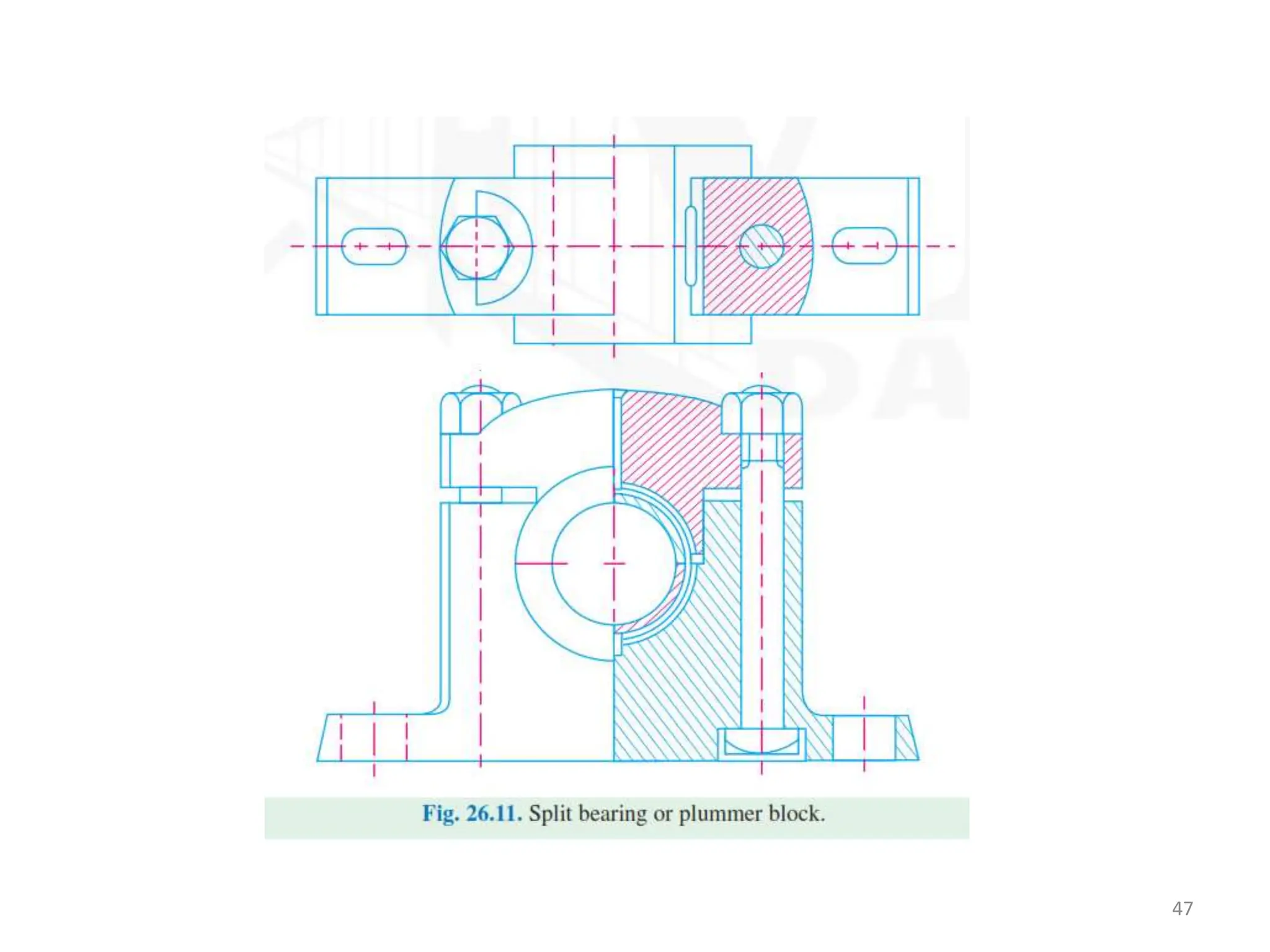

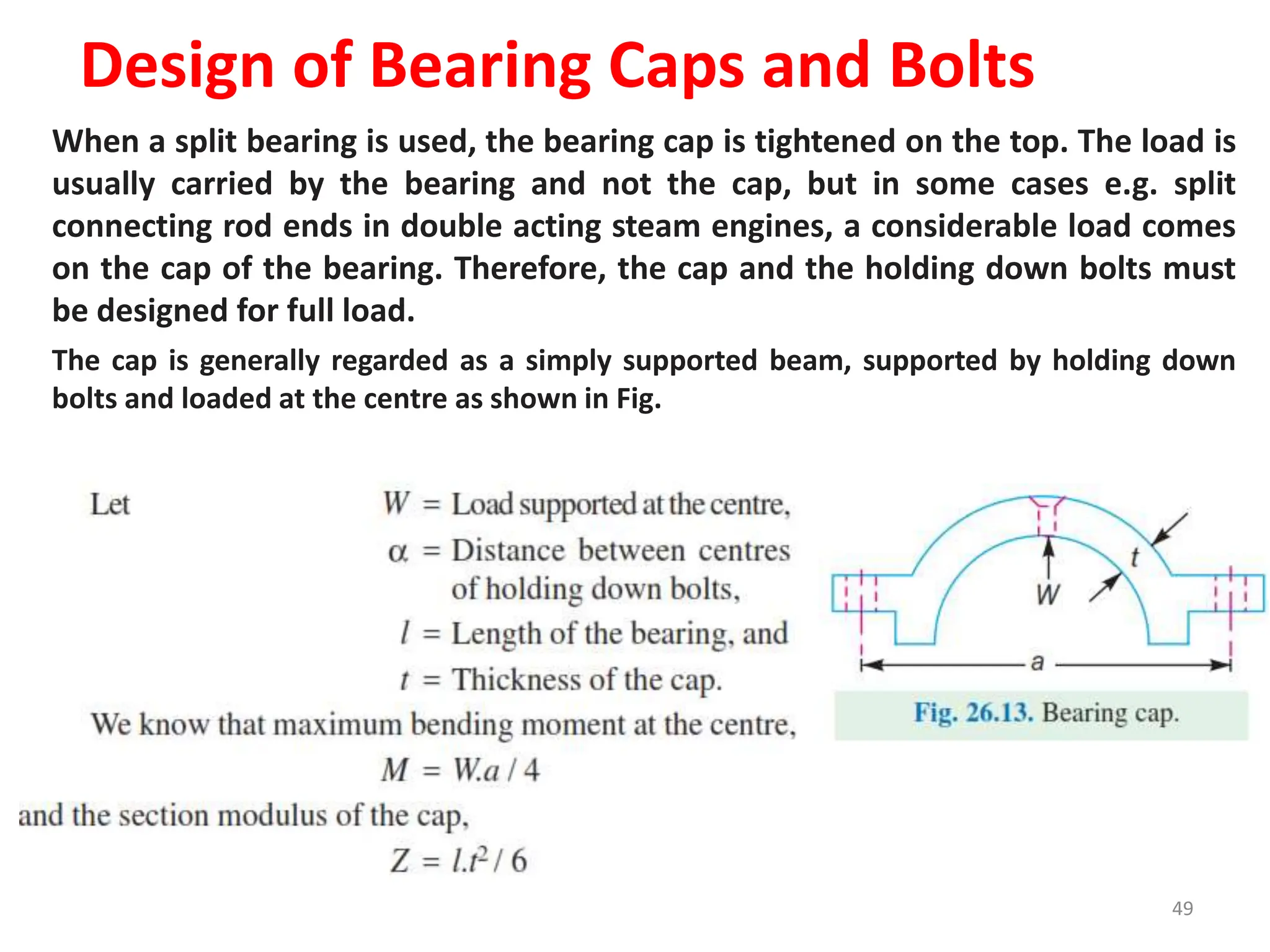

This document provides information about sliding contact bearings. It defines key terms used in hydrodynamic journal bearings such as diametral clearance, eccentricity, and bearing characteristic number. It also discusses different types of bearings like solid, bushed, split, and thrust bearings. Examples are provided to show how to calculate load capacity, power lost to friction, and heat generated in different bearing types. Design steps for hydrodynamic journal bearings are also outlined.