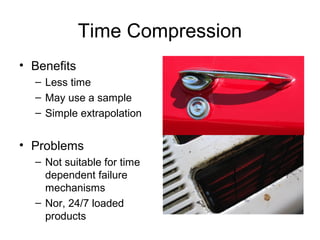

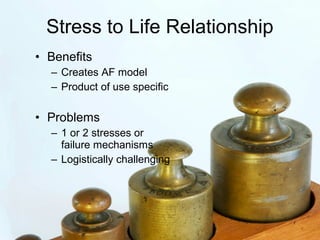

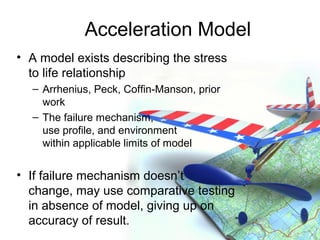

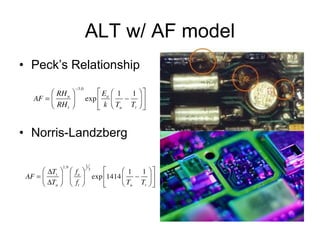

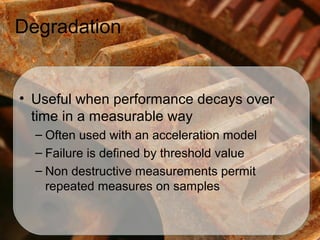

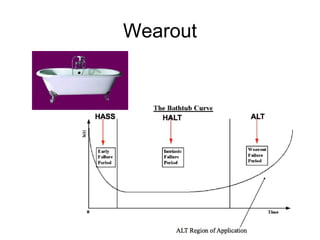

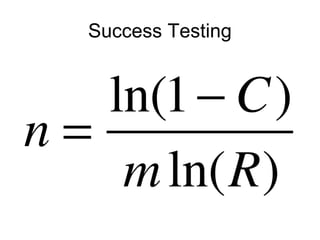

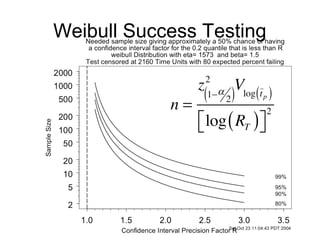

This document discusses different approaches to accelerated life testing (ALT). It introduces the thought process for selecting an ALT approach, discusses trade-off decisions, and enables selecting the right approach for a given situation. The key approaches discussed are: real-time testing with no constraints; time compression testing using increased usage cycles; applying an acceleration model relating stress to life; step stress testing; degradation testing; and Weibull success testing. Guiding principles are to respect constraints, use real usage conditions, minimize assumptions, and focus on failure mechanisms.