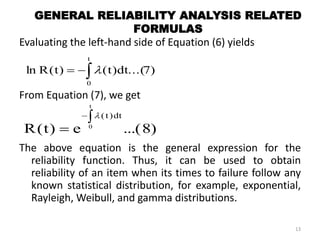

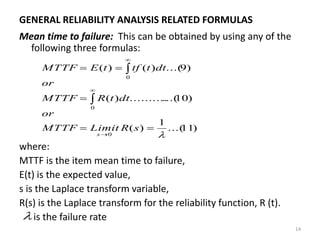

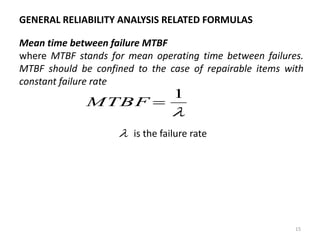

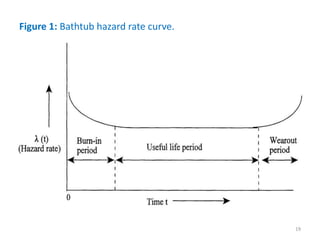

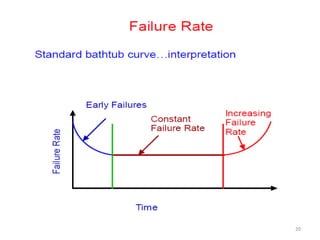

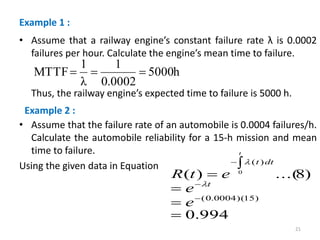

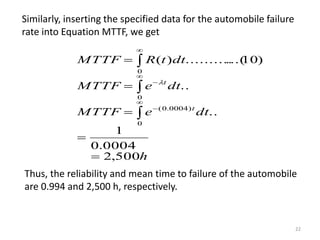

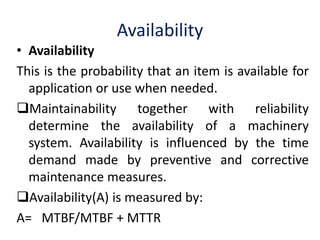

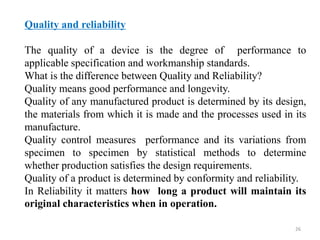

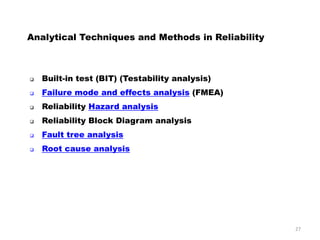

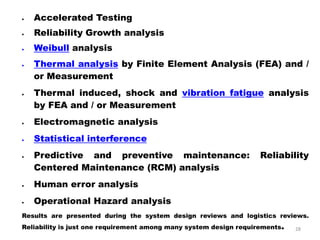

This document discusses implementing reliability strategies and engineering. It begins by explaining the importance of reliability in fields like aviation, defense, and energy where failure could lead to dangerous situations. It then discusses mechanical reliability and common failure modes. Reliability engineering is introduced as the study of reliability and life-cycle management. Several high-profile system failures are listed to emphasize the need for reliability in design. The document outlines various areas of reliability engineering and provides definitions of key terms. It gives examples of reliability calculations and discusses maintainability, availability, and quality. Analytical reliability techniques are also summarized, along with key points and steps to implement a reliability strategy.