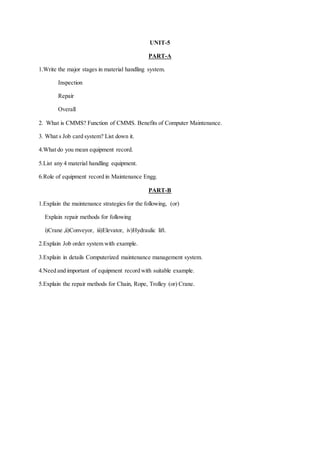

This document outlines the topics covered in 5 units on maintenance engineering. It includes definitions of key terms, explanations of maintenance strategies and systems, discussions of reliability and failure analysis techniques, and descriptions of condition monitoring tools and processes. The overall document focuses on planning and optimizing maintenance to improve equipment reliability, availability, and safety while reducing costs. It covers both traditional and computer-based approaches.