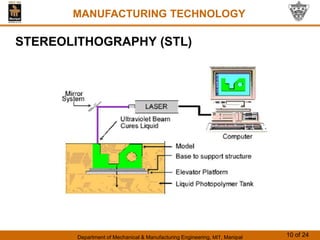

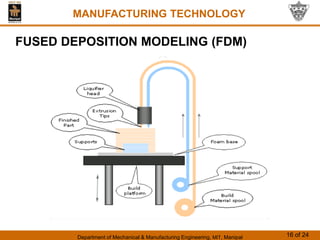

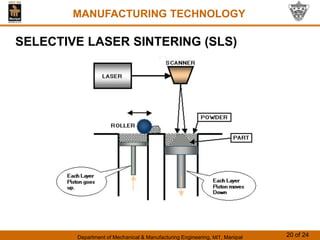

The document discusses rapid prototyping, which uses additive manufacturing techniques to automatically create physical prototypes from 3D CAD models in a short period of time. It specifically describes stereolithography, fused deposition modeling, and selective laser sintering as common rapid prototyping methods that build parts layer by layer from materials like plastic or metal powder. Rapid prototyping allows faster design iteration and testing compared to traditional prototyping methods.