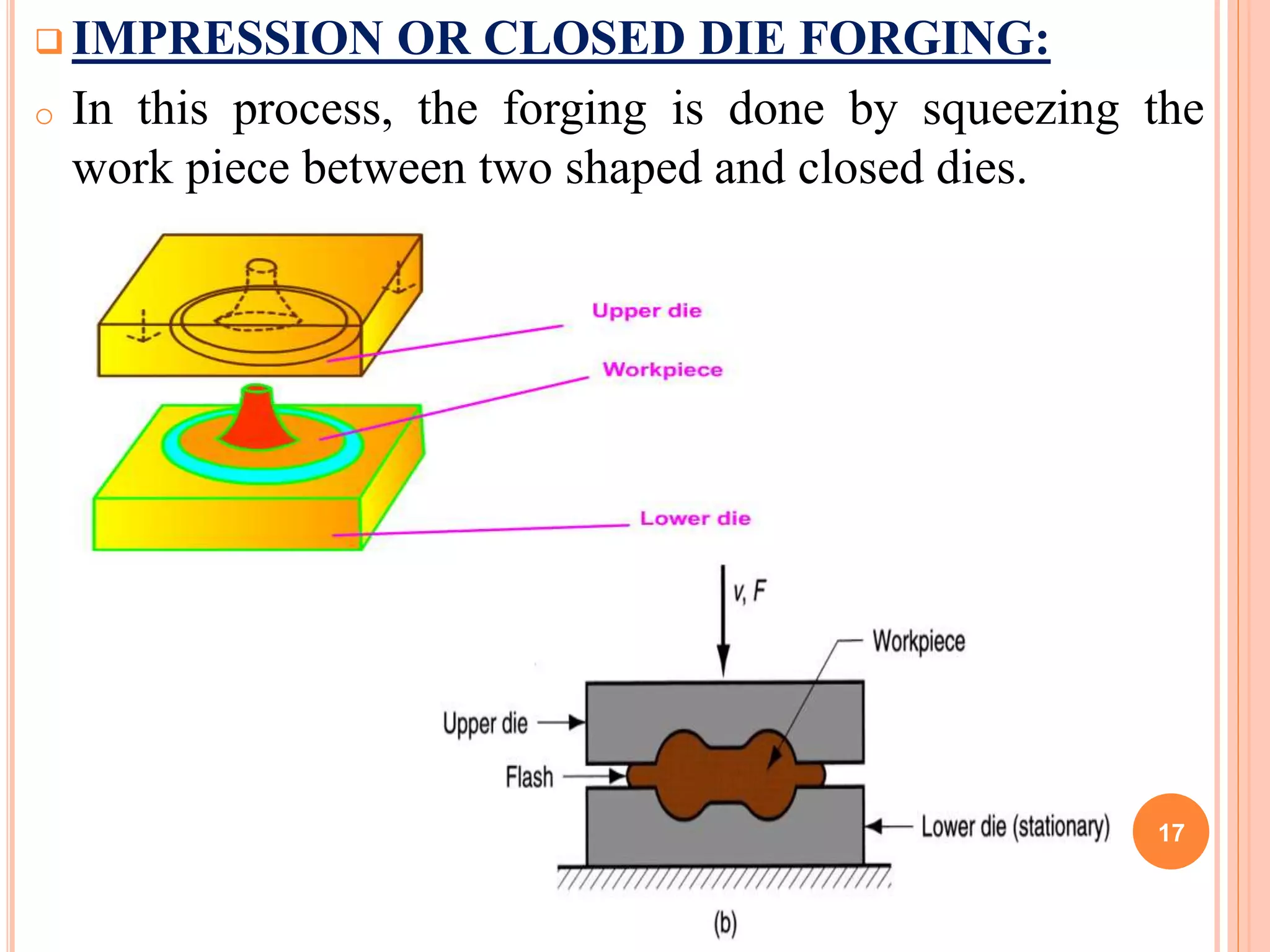

Bulk metal forming processes change the shape of metal parts through plastic deformation. Hot working above the metal's recrystallization temperature allows for significant shape changes with less force. Cold working below this temperature increases strength but requires more force. Common bulk metal forming processes include forging, rolling, and extrusion, which can produce parts near their final net shape with little waste.