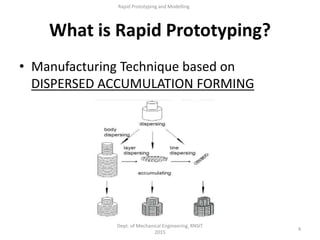

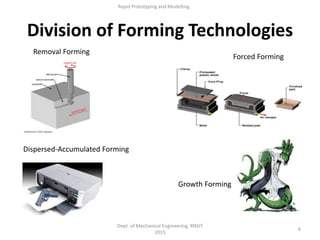

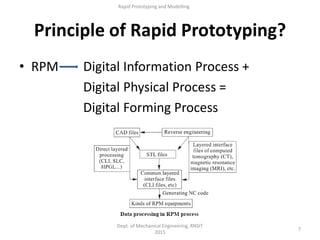

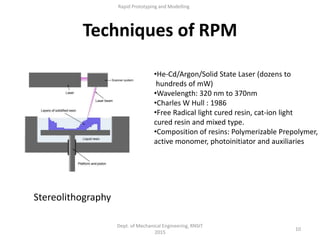

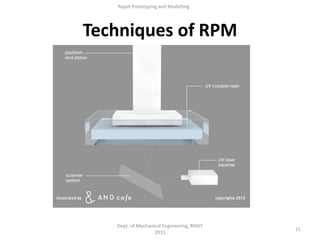

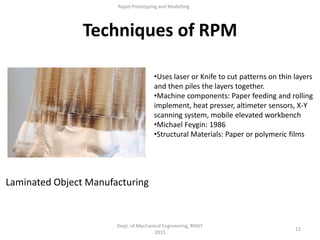

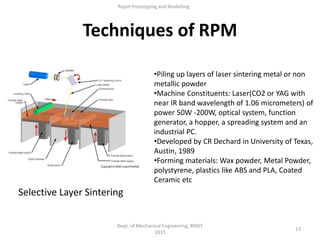

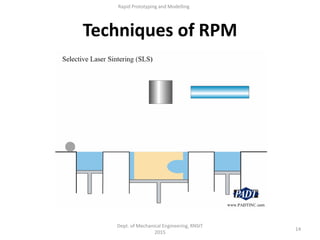

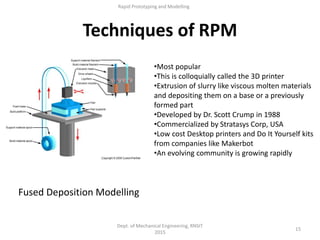

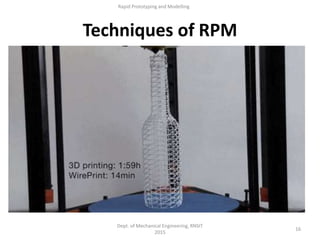

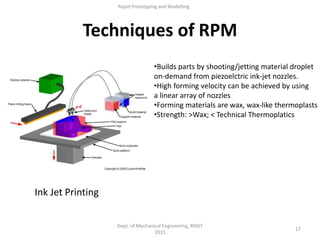

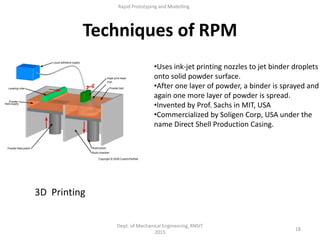

This document provides an introduction to rapid prototyping and modeling. It defines rapid prototyping as using manufacturing techniques based on dispersed accumulation forming to quickly produce preliminary versions of devices from which other forms are developed. The document outlines several rapid prototyping techniques such as stereolithography, laminated object manufacturing, selective layer sintering, fused deposition modeling, and ink jet printing. It also discusses the history and principles of rapid prototyping and its applications in rapid manufacturing, tooling, and molding.