1. Rapid prototyping is a group of techniques that quickly fabricate a scale model of a physical part using 3D computer-aided design data through additive layer manufacturing. 2. The document discusses the history and development of rapid prototyping technologies from the 1980s onward. 3. It describes common rapid prototyping processes like stereolithography, selective laser sintering, and fused deposition modeling which build parts layer-by-layer from materials in different states of matter.

![2

Seminar Report 2015 Rapid Prototyping

2. Design for Rapid Manufacture

3. Organization and Implementation

UK funded research projects in all these areas have commenced within the RMRG and this

paper discusses some results of work into the design optimization and customization aspects that

are enabled by RM. The results are derived from the ‘Design for Rapid Manufacture’ and

‘Management, Organizational and Implementation of Rapid Manufacturing’ (Man RM) projects.

It should be noted that although the Man RM project is principally concerned with the

management implications of RM, much work has also been carried out into what is becoming a

significantly important area for business – the area of customization and personalization of

products. It should be noted that an assumption on the projects has been made that the viable

Rapid Manufacturing process have been developed that additively produce end-use parts in

suitable materials and with acceptable surface finish, accuracy and speed.

As with CNC subtractive methods, the CAD-CAM workflow in the traditional Rapid

Prototyping process starts with the creation of geometric data, either as a 3D solid using

a CAD workstation, or 2D slices using a scanning device. For RP this data must represent a valid

geometric model; namely, one whose boundary surfaces enclose a finite volume, contains no

holes exposing the interior, and do not fold back on themselves. In other words, the object must

have an inside. The model is valid if for each point in 3D space the computer can determine

uniquely whether that point lies inside, on, or outside the boundary surface of the

model. CAD post-processors will approximate the application vendors’ internal CAD geometric

forms (e.g., B-spines) with a simplified mathematical form, which in turn is expressed in a

specified data format which is a common feature in Additive Manufacturing: STL

(stereolithography) a de facto standard for transferring solid geometric models to SFF machines.

To obtain the necessary motion control trajectories to drive the actual SFF, Rapid

Prototyping, 3D Printing or Additive Manufacturing mechanism, the prepared geometric model

is typically sliced into layers, and the slices are scanned into lines [producing a "2D drawing"

used to generate trajectory as in CNC`s tool path], mimicking in reverse the layer-to-layer

physical building process.

1.1 HISTORY

Dept. of Mechanical Engg. AXIS CET](https://image.slidesharecdn.com/rapidprototypiung-150806084332-lva1-app6892/85/Rapid-prototyping-2-320.jpg)

![3

Seminar Report 2015 Rapid Prototyping

In the 1980s U.S. policy makers and industrial managers were forced to take note that

America's dominance in the field of machine tool manufacturing evaporated, in what was named

the machine tool crisis. Numerous projects sought to counter these trends in the

traditional CNC CAM area, which had begun in the US. Later when Rapid Prototyping Systems

moved out of labs to be commercialized it was recognized that developments were already

international and U.S. rapid prototyping companies would not have the luxury of letting a lead

slip away. The National Science Foundation was an umbrella for the National Aeronautics and

Space Administration (NASA), the US Department of Energy, the US Department of

Commerce NIST, the US Department of Defense, Defense Advanced Research Projects

Agency (DARPA), and the Office of Naval Research coordinated studies to inform strategic

planners in their deliberations. One such report was the 1997 Rapid Prototyping in Europe and

Japan Panel Report in which Joseph J. Beaman founder of DTM Corporation DTM RapidTool

pictured] provides a historical perspective: The roots of rapid prototyping technology can be

traced to practices in topography and photo sculpture. Within TOPOGRAPHY Blanther (1892)

suggested a layered method for making a mold for raised relief paper topographical maps .The

process involved cutting the contour lines on a series of plates which were then stacked.

Matsubara (1974) of Mitsubishi proposed a topographical process with a photo-

hardening photopolymer resin to form thin layers stacked to make a casting mold.

PHOTOSCULPTURE was a 19th-century technique to create exact three-dimensional replicas of

objects. Most famously Francois Willeme (1860) placed 24 cameras in a circular array and

simultaneously photographed an object. The silhouette of each photograph was then used to

carve a replica. Morioka (1935, 1944) developed a hybrid photo sculpture and topographic

process using structured light to photographically create contour lines of an object. The lines

could then be developed into sheets and cut and stacked, or projected onto stock material for

carving. The Munz (1956) Process reproduced a three-dimensional image of an object by

selectively exposing, layer by layer, a photo emulsion on a lowering piston. After fixing, a solid

transparent cylinder contains an image of the object.

The technologies referred to as Solid Freeform Fabrication are what we recognize today as

Rapid Prototyping, 3D Printing or Additive Manufacturing: Swainson (1977), Schwerzel (1984)

Dept. of Mechanical Engg. AXIS CET](https://image.slidesharecdn.com/rapidprototypiung-150806084332-lva1-app6892/85/Rapid-prototyping-3-320.jpg)

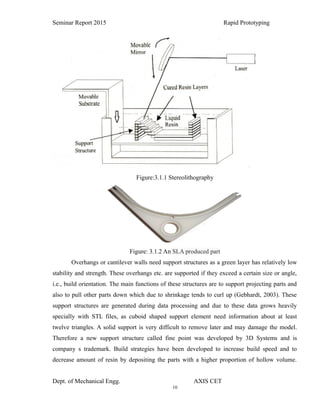

![18

Seminar Report 2015 Rapid Prototyping

optimisation techniques and then subsequently fabricated. However, this impossible to make due

to DFM criteria – this is one of the main stumbling blocks for so-called Knowledge Based

Engineering (KBE) systems that often have FEA as the kernel. The design optimisation is

followed by the application of industrial design to the FEA optimised product in order to produce

a hybrid design that encompasses both engineering and aesthetic aspects. This approach follows

the conclusions of a previous investigation for Custom Design Technologies (formerly Bafbox)

that was undertaken during the Design for RM research project [7]. During this work, it was

speculated that as DFM criteria are no longer valid with the advent of RM, then a hybrid design

methodology will emerge where the industrial designer would be able to manufacture any design

that they desire without the need to consider DFM. Thus, there would be an overriding need for

them to incorporate some engineering aspects in their product design. This investigation extends

this principle by incorporating design optimisation and aesthetic design in a single product

design methodology.

MG Rover is currently looking into ways to modularise their product range by modularizing the

components that go to make up different vehicle variants, thus reducing the costs of production

for those vehicles. One part of considerable interest to MG Rover was the development of a

modular handbrake. Currently an expensive metal stamped device is used and these components

are individual to each vehicle variant. In order to provide a more cost effective solution MG

Rover are investigating the use of an injection molded handbrake lever – with a metal ratchet

mechanism, that could be common across the vehicle range. As such, a handbrake lever from the

Rover 75 has been redesigned with injection moulding criteria in mind. As part of their

involvement in the Design for Rapid Manufacture project, MG Rover agreed to perform a

concurrent study to investigate how the design of the handbrake lever would change with the

advent of Rapid Manufacturing with an emphasis on material minimisation. It was a requirement

of the RM designed lever to fit to the ratchet mechanism that had previously been developed for

the injection-molded handbrake.

4.1.4 DESIGN CUSTOMISATION

One area where Rapid Manufacturing could have a significant impact on both customers and

Dept. of Mechanical Engg. AXIS CET](https://image.slidesharecdn.com/rapidprototypiung-150806084332-lva1-app6892/85/Rapid-prototyping-18-320.jpg)