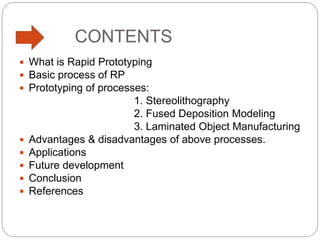

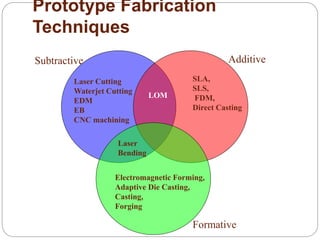

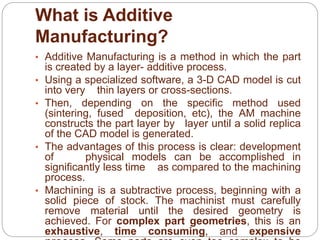

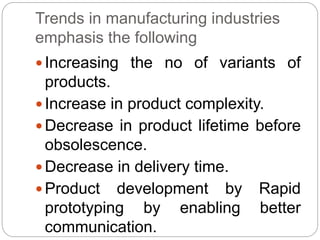

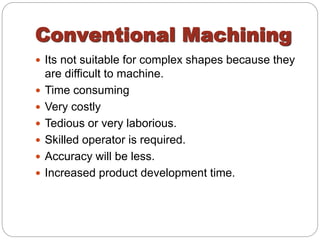

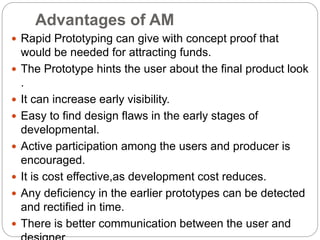

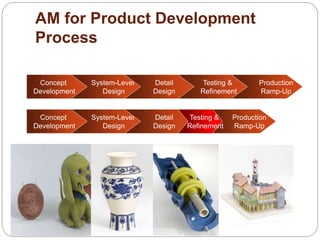

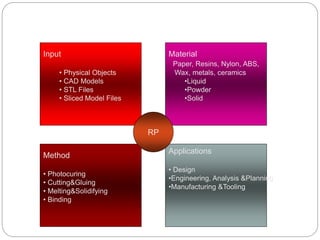

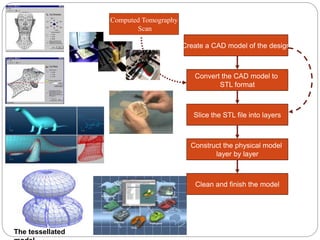

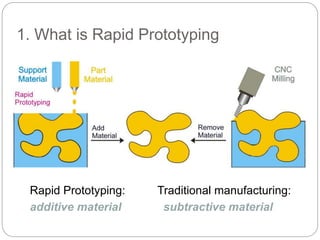

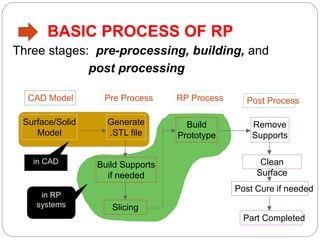

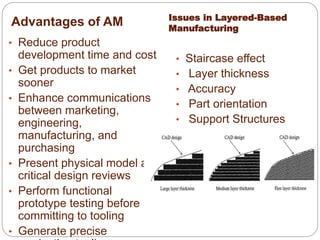

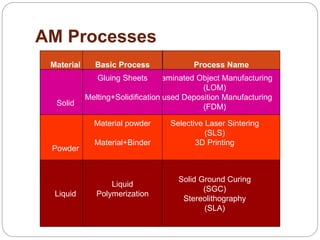

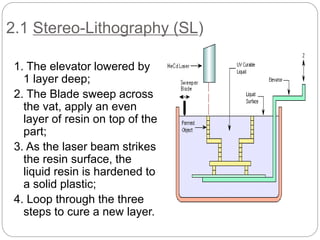

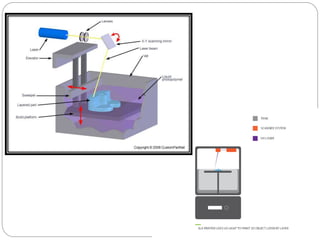

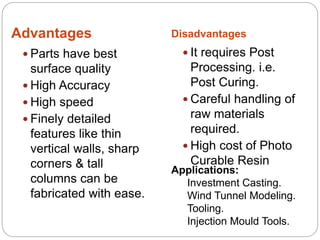

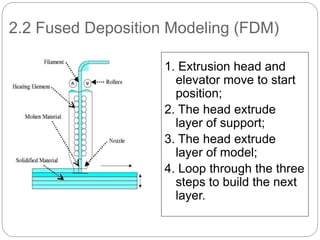

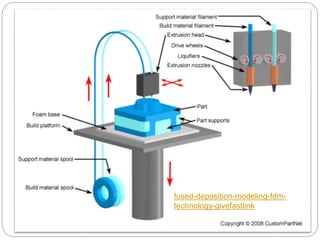

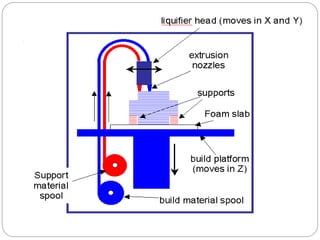

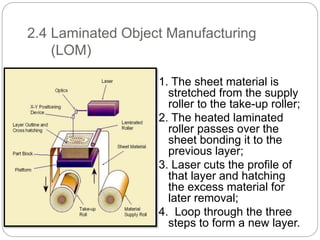

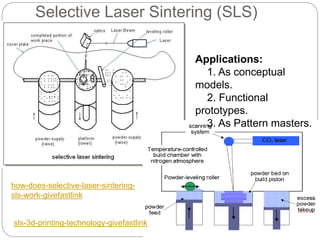

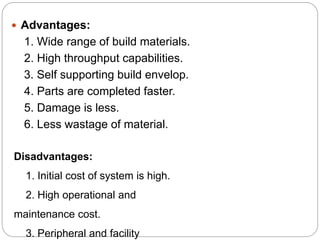

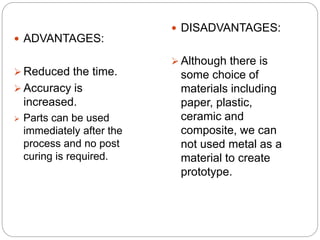

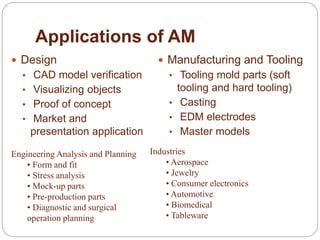

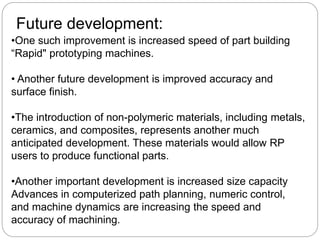

The document presents an overview of rapid prototyping, detailing its definition, basic processes, advantages, and disadvantages. It compares additive manufacturing with traditional machining, emphasizing its efficiency, time savings, and cost-effectiveness in product development. Additionally, it discusses various prototyping techniques, applications, and future developments, highlighting the technology's potential to revolutionize manufacturing in various industries.