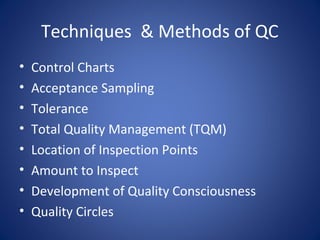

This document discusses quality control, including its definition, objectives, need, stages, types, and techniques. Quality control refers to setting standards for product characteristics and quality development/maintenance to achieve economic production and customer satisfaction. The objectives of quality control are to provide uniform, satisfactory, and economical products that prevent defects. Quality control techniques include establishing quality policies, determining standards, inspection of materials and finished products, statistical techniques, and control actions.