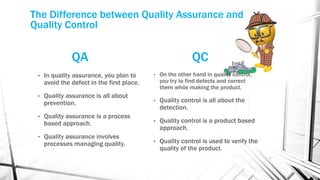

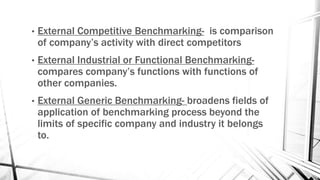

The document discusses quality control, quality assurance, and total quality management. It defines quality as meeting or exceeding customer expectations through consistent standards and processes. Quality control focuses on identifying defects during production, while quality assurance aims to prevent defects through upfront planning and audits. Both work together to deliver high quality outputs, increase efficiency, and ensure customer satisfaction. Total quality management requires company-wide commitment to quality through elements like training, teamwork, statistical methods, and customer service. It also discusses quality design, benchmarking, and factors important for quality in the construction industry.