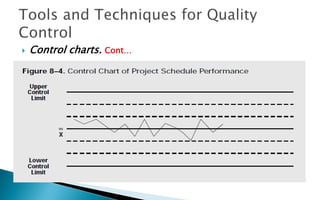

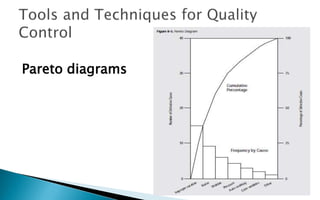

The document discusses quality control in project management. It defines quality control as monitoring project results to ensure they meet quality standards. It should be performed throughout the project on both product and management results. Quality control is often done by a dedicated department but does not have to be. The project team should understand statistical quality control concepts. Quality control involves work results, quality plans, definitions, checklists, inspections, control charts, sampling, flowcharting and trend analysis to identify issues and make improvements.