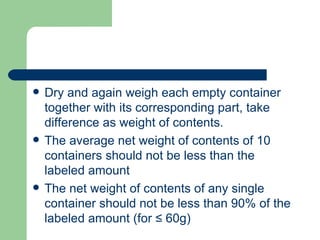

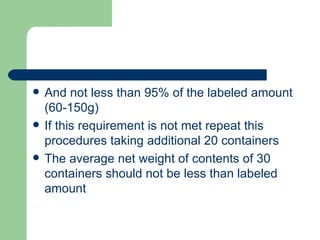

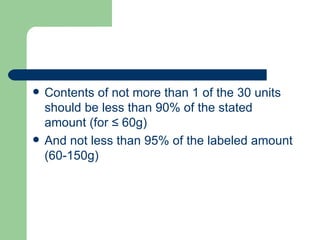

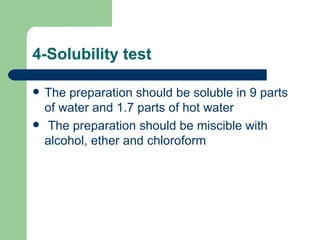

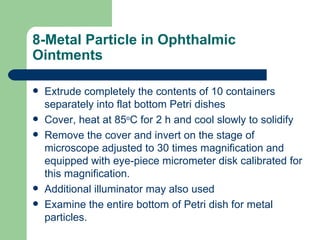

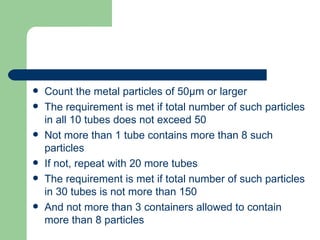

This document outlines 8 key tests for evaluating ointments and creams: [1] Physical appearance to check for cracking, changes in viscosity, or microbial growth. [2] Particle size determination under a microscope. [3] Weight variation testing of labeled amounts. [4] Solubility testing in water and alcohol. [5] Viscosity determination using specified methods. [6] Assay of active ingredients within official limits. [7] Microbial contamination testing using inoculation or membrane filtration. [8] Testing for metal particles in ophthalmic ointments under a microscope.