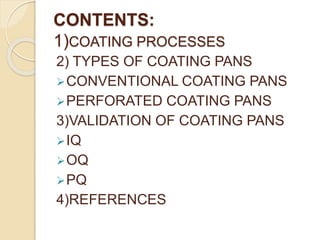

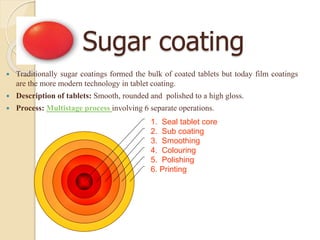

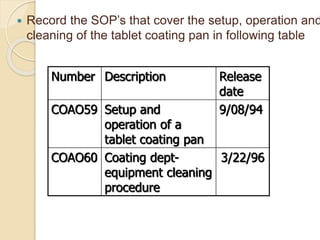

This document discusses coating pans used in the pharmaceutical industry. It describes two main types of coating pans - conventional and perforated. Conventional pans include Pelligrini, immersion sword, and immersion tube pans. Perforated pans have openings that improve mixing and drying efficiency, examples given are Accela-Cota, Hi-Coater, Dria Coater, and Glatt pans. The validation process for coating pans involves installation qualification to confirm proper installation, operational qualification to establish operating parameters, and performance qualification to verify operation as intended.