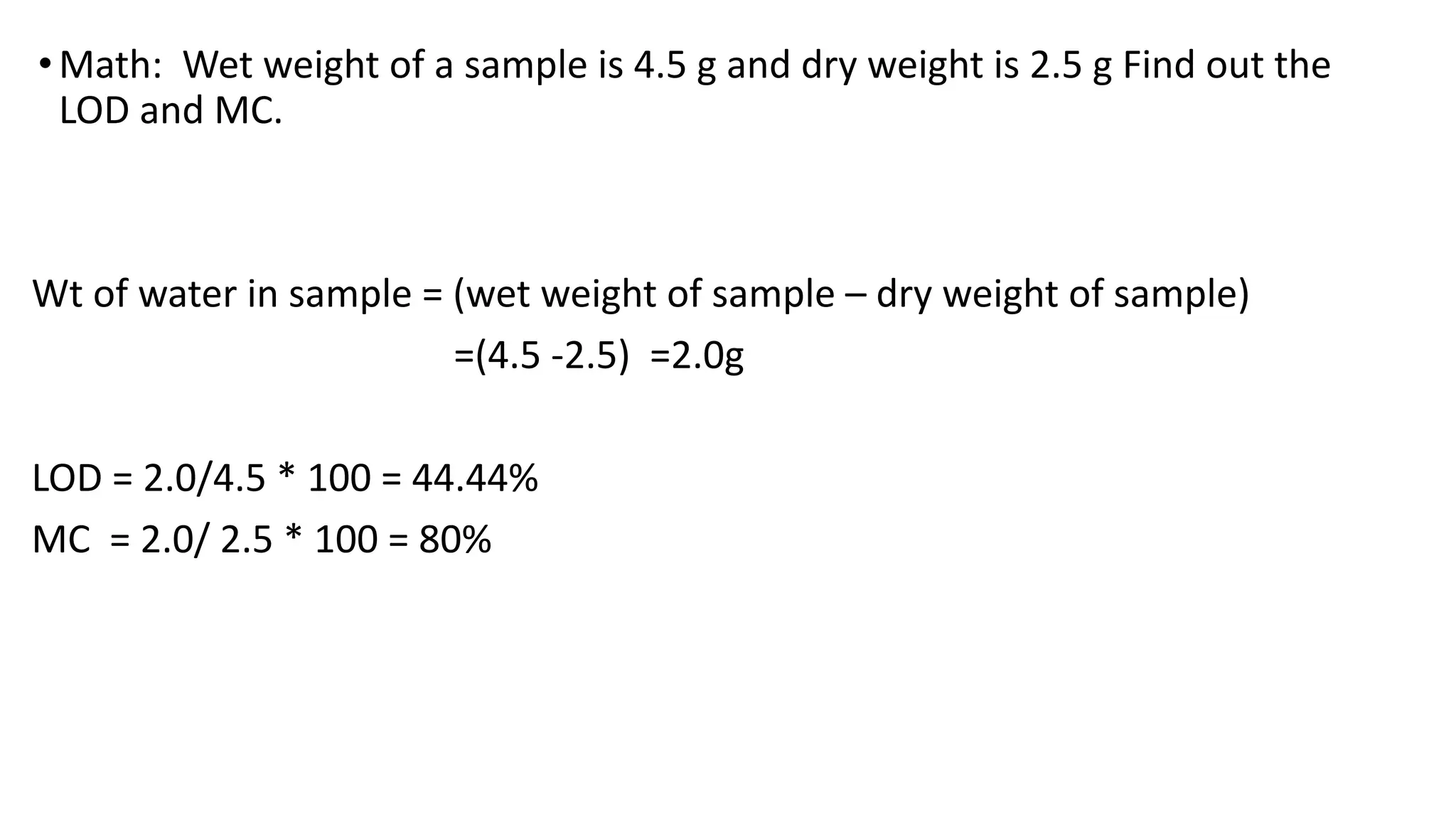

Pharmaceutical chemistry involves the study of drugs, including their development, discovery, delivery, absorption, and metabolism. Pharmaceutical raw materials include chemicals, extracts, and elements used to manufacture drugs. Drying removes liquid from materials through heat transfer to reduce bacterial growth, prepare granules, reduce bulk weight, and increase stability. Raw materials include active pharmaceutical ingredients (APIs) that have pharmacological effects and excipients that aid drug delivery without pharmacological effects.