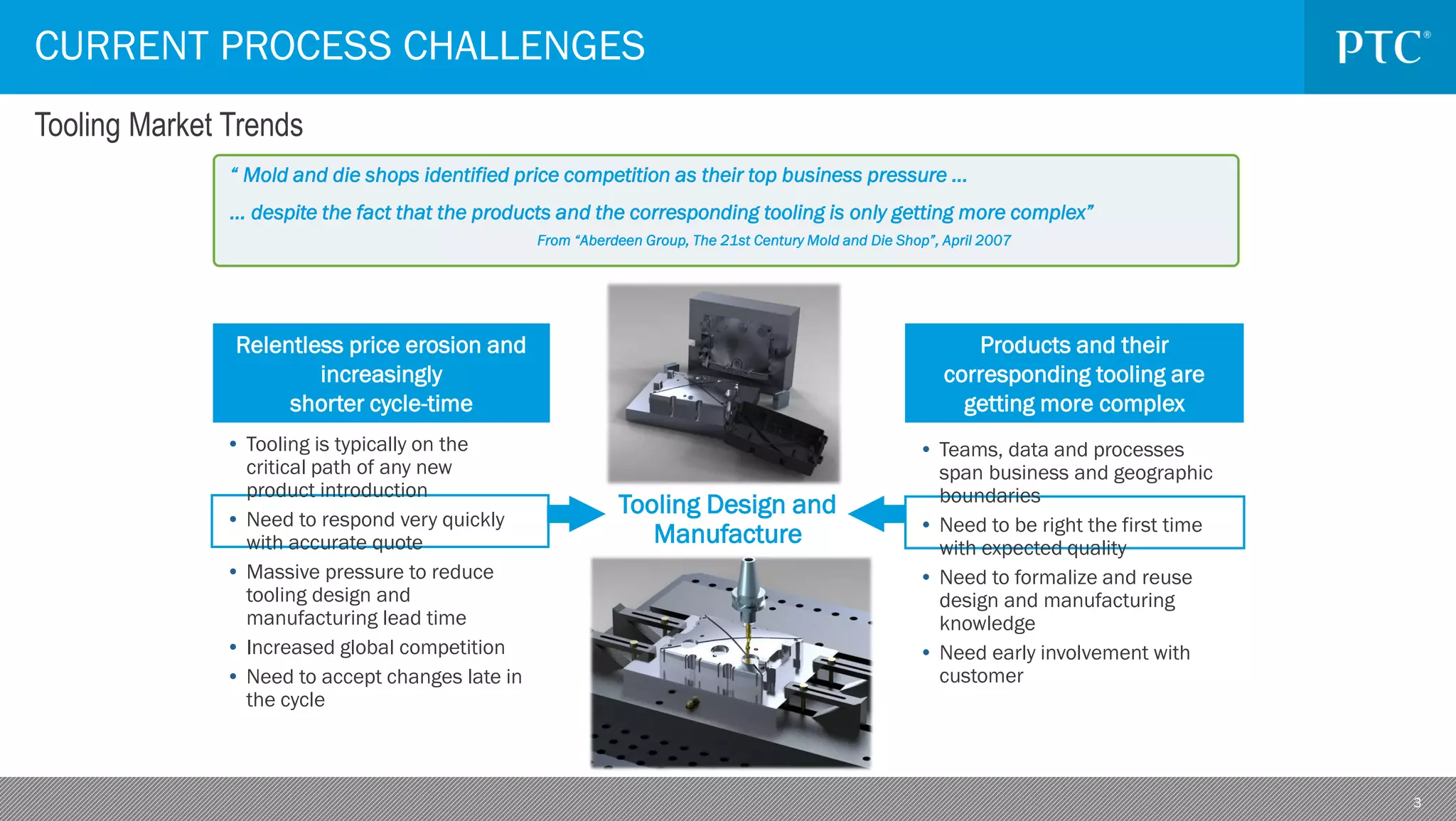

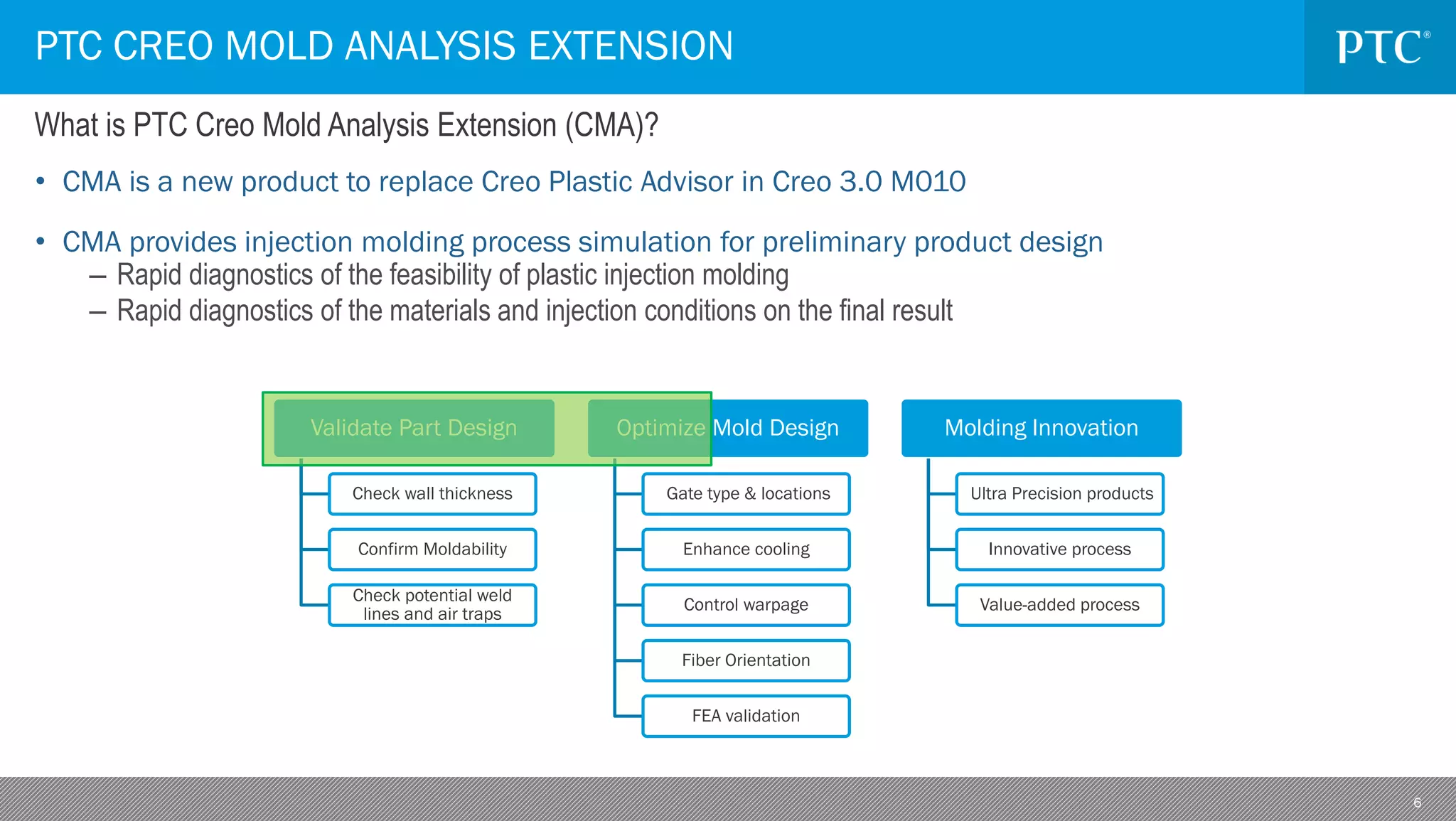

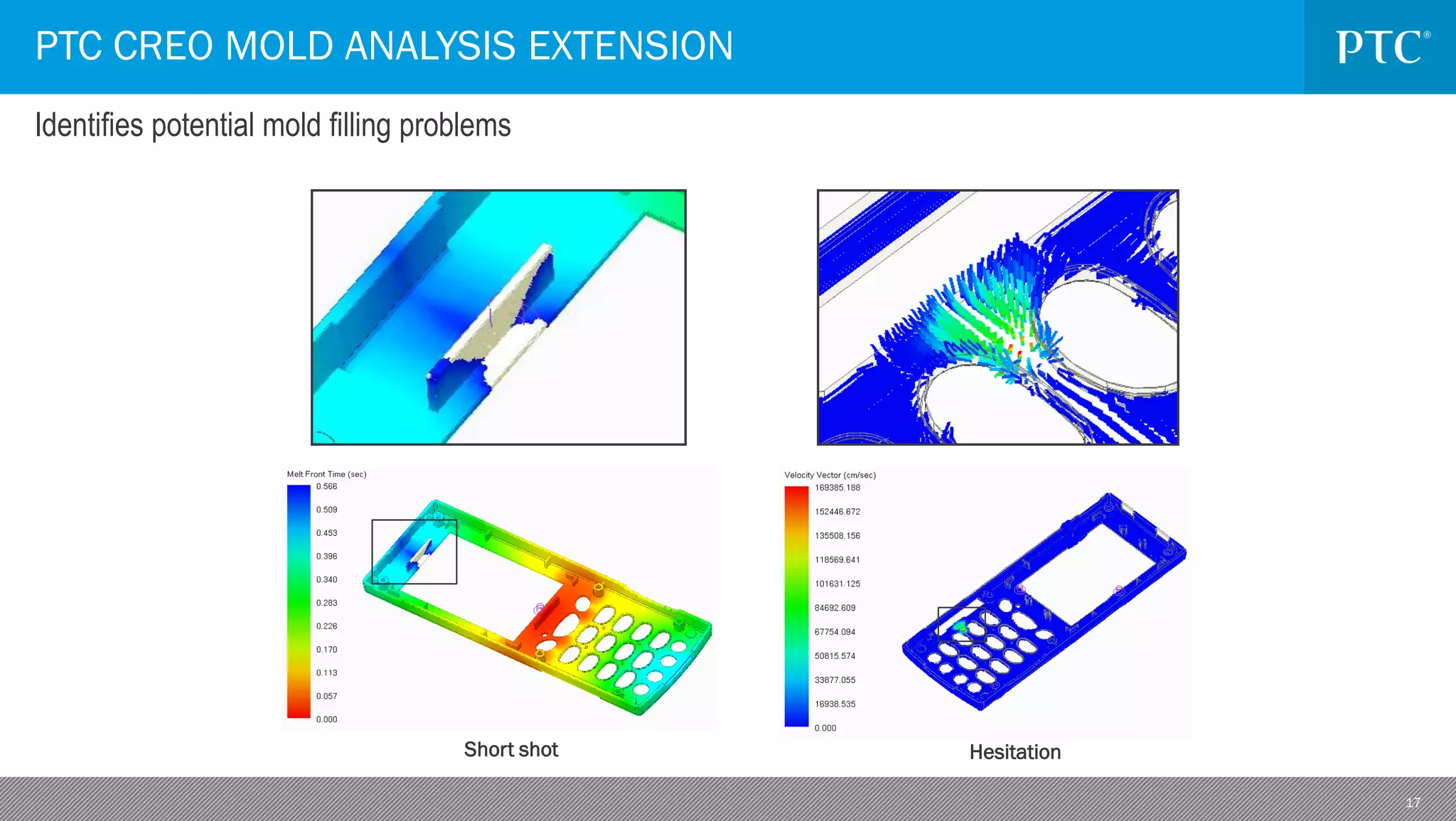

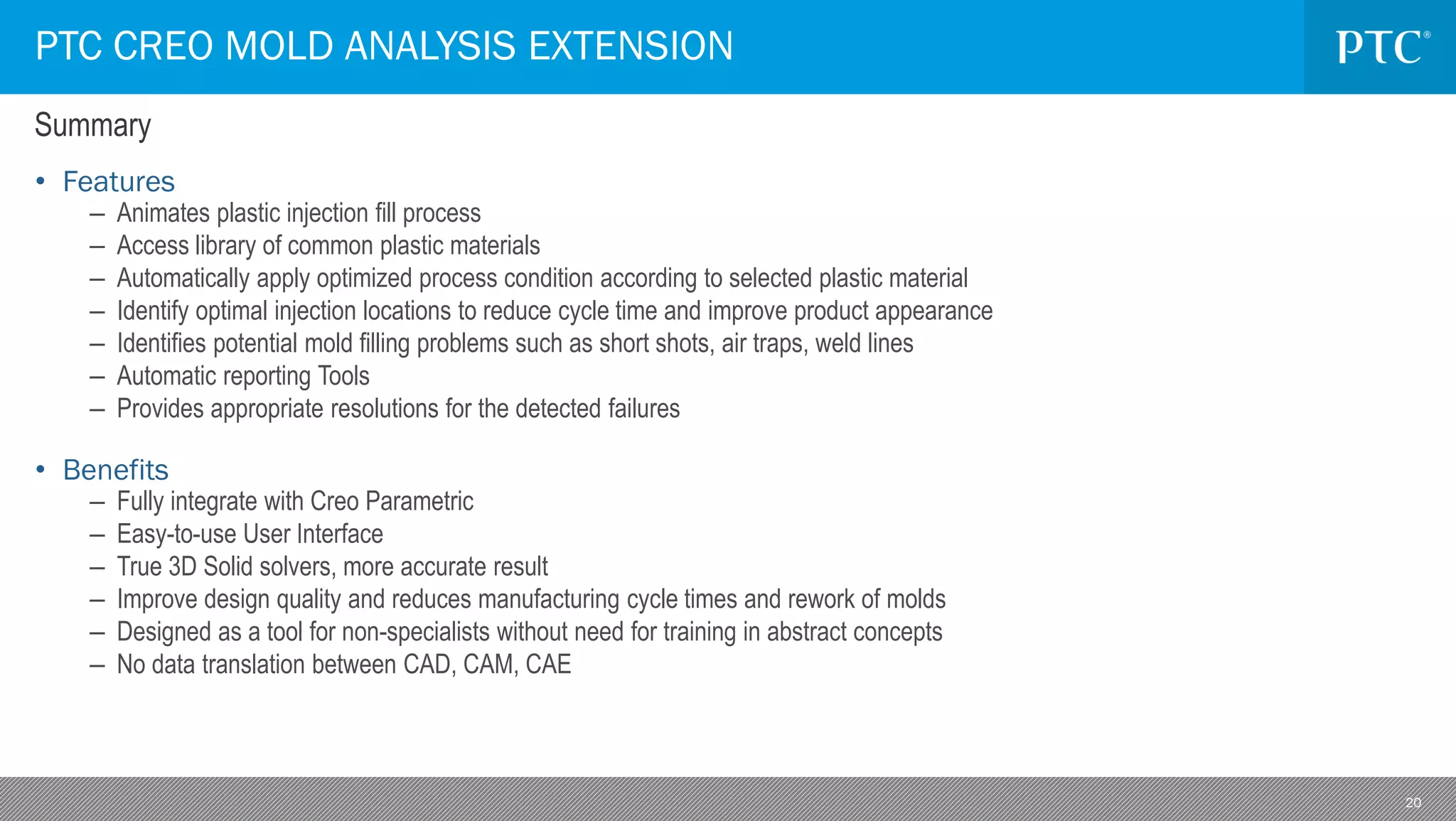

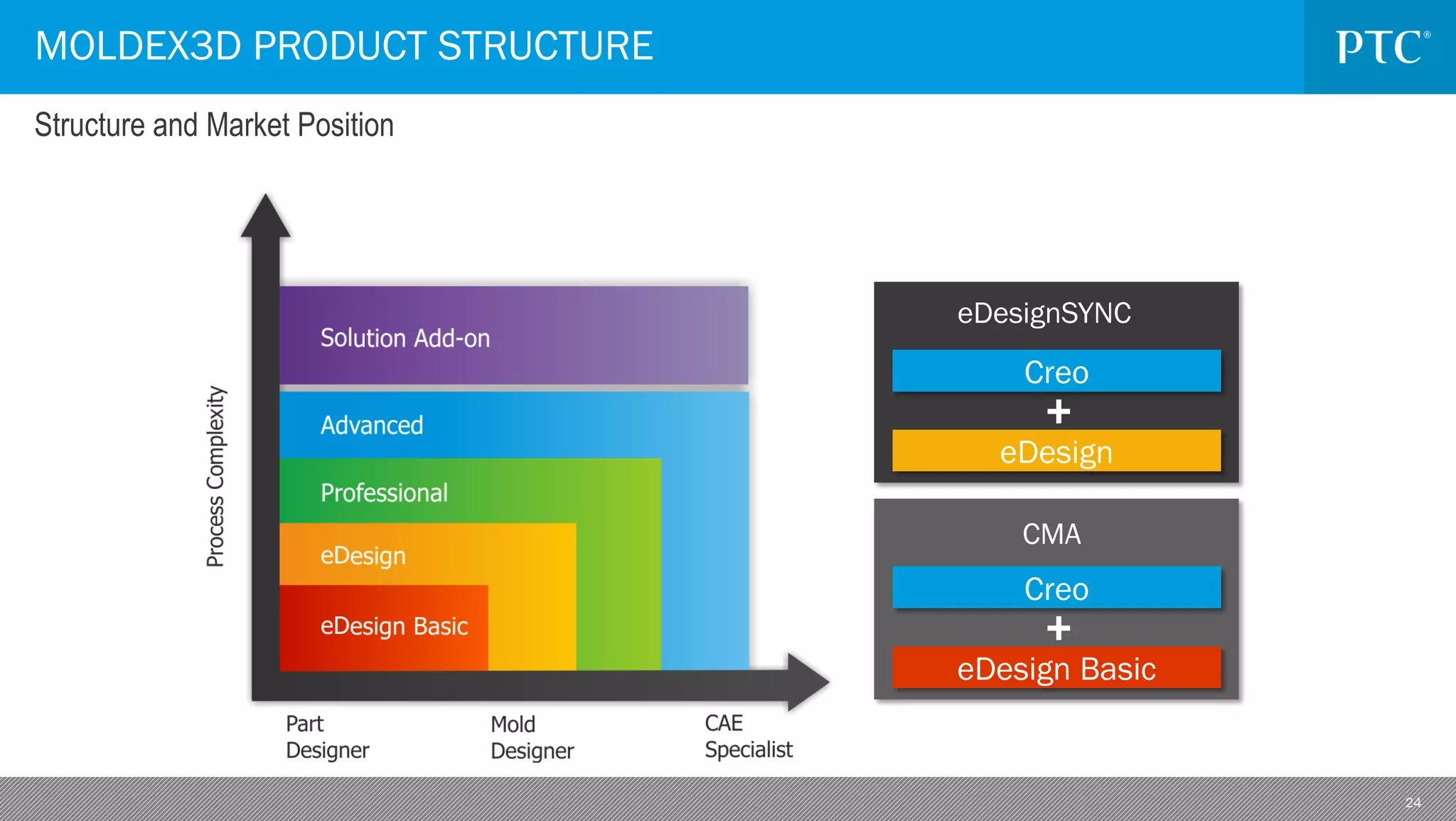

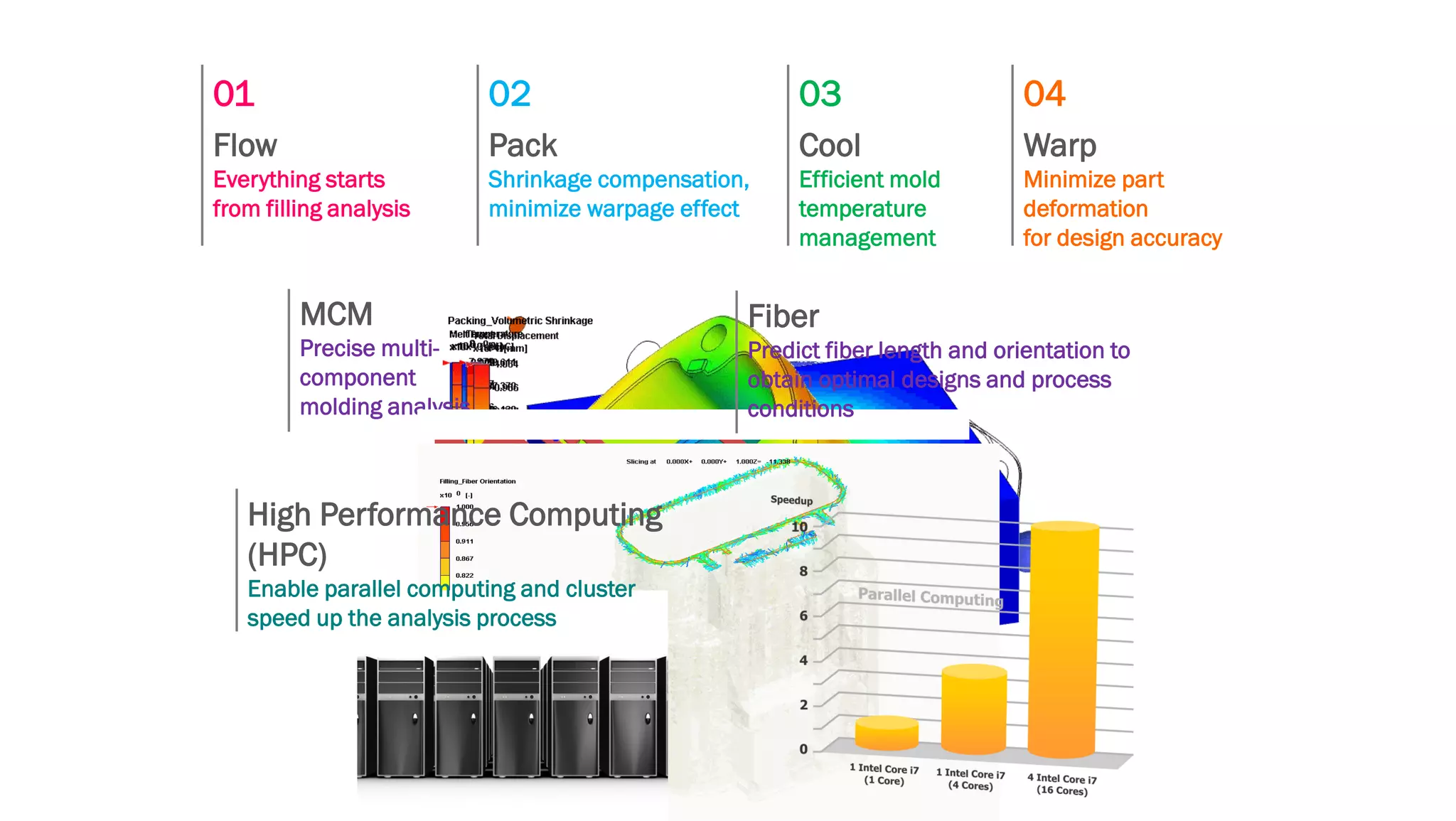

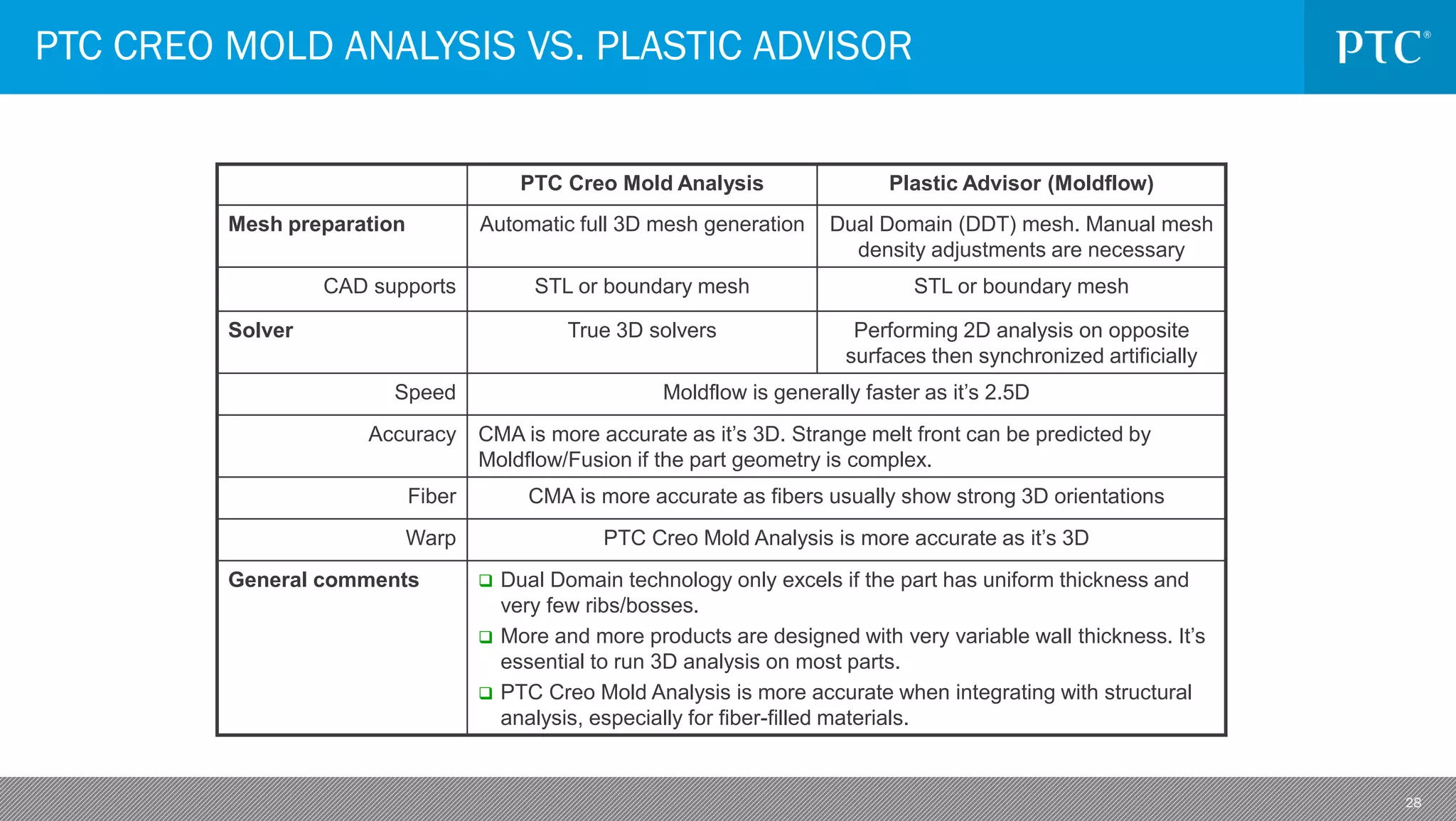

The document provides an overview of PTC Creo Mold Analysis Extension (CMA). It discusses current challenges in injection molding processes that lead to high costs. CMA provides injection molding simulations within Creo to validate part design, optimize the mold design, and improve molding processes. It features an intuitive interface and identifies potential filling issues and recommendations. CMA is integrated with Creo and provides accurate 3D simulations to reduce costs from mold rework.