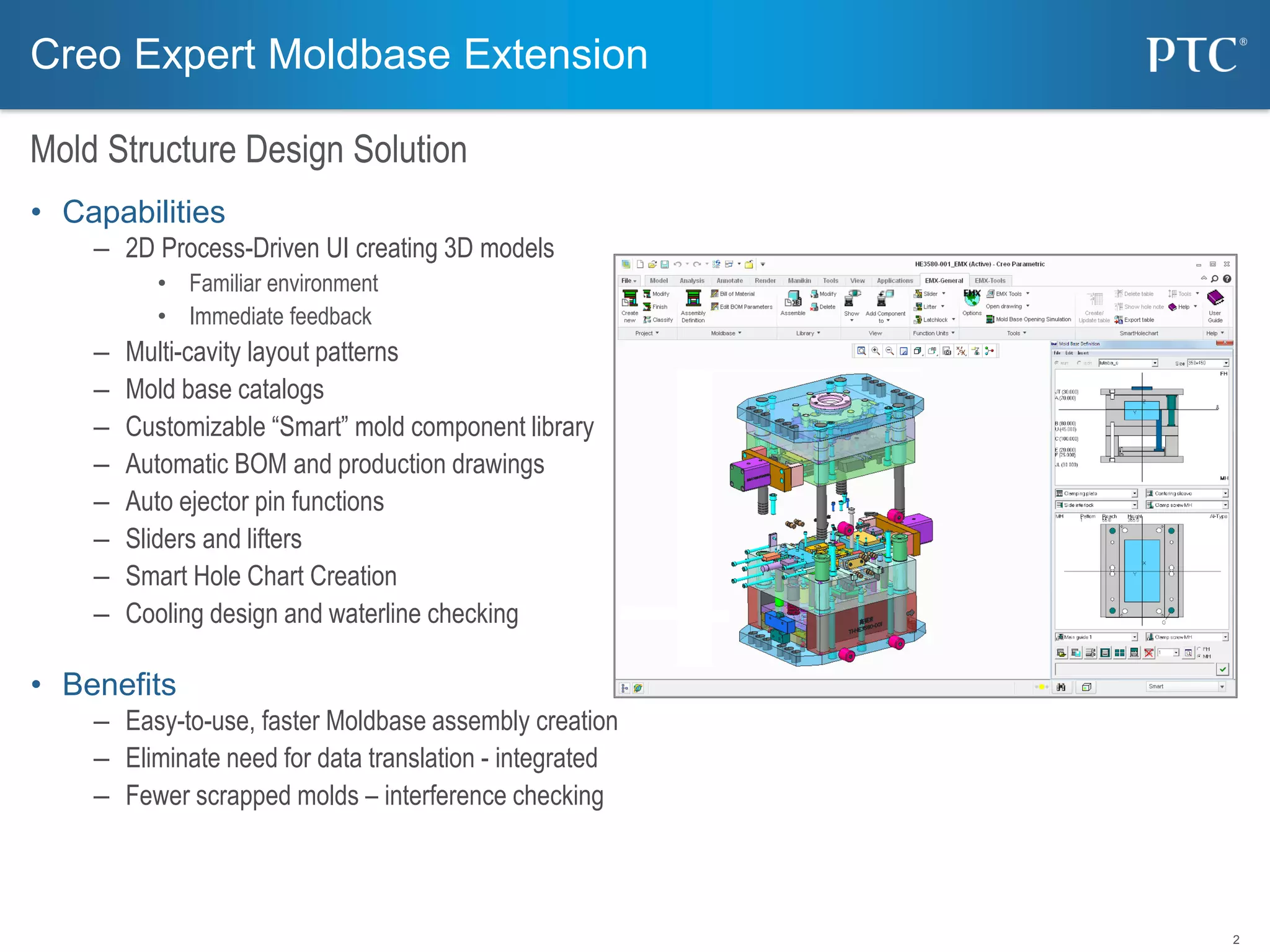

The PTC Creo Expert Moldbase Extension (EMX) provides capabilities for 2D process-driven moldbase assembly creation with integrated mold component libraries, automatic BOM generation, interference checking, and other mold design functions. It aims to make moldbase design easier and faster compared to traditional 3D modeling. Key capabilities include multi-cavity layout patterns, catalogs of standard mold bases, customizable mold components, and automatic production drawings. The EMX is integrated with Creo Parametric for a unified mold design solution.