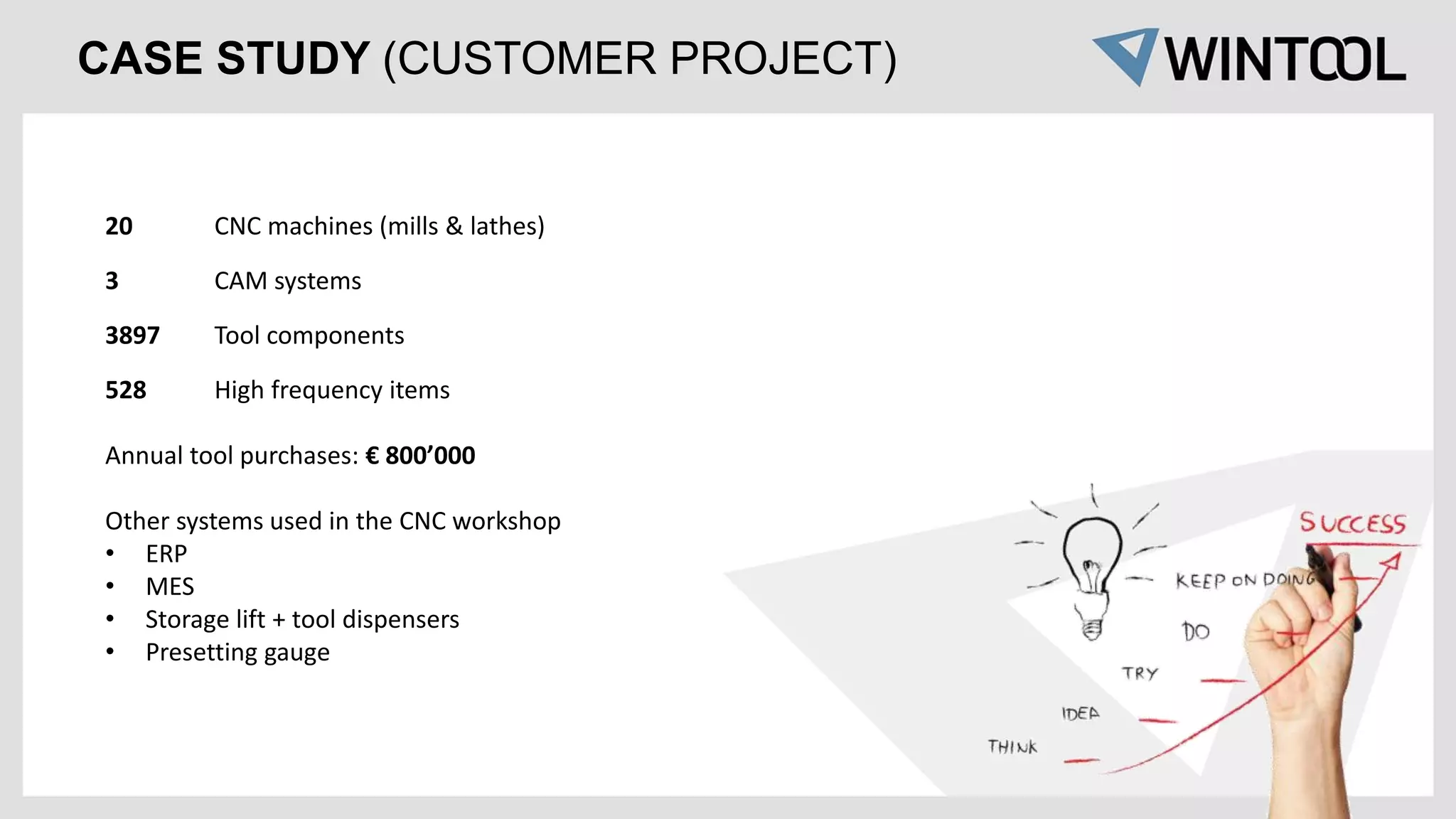

Tool Assembly & Presetting Total per Year WinTool process improvements Potential savings

Tool assemblies per month 500

10 min 50% 5 min 25’000 €

Operator: Tool Change & Setup Total per Year WinTool process improvements Potential savings

Setup time per job 30 min

10 jobs/day 20% 24 min 120’000 €

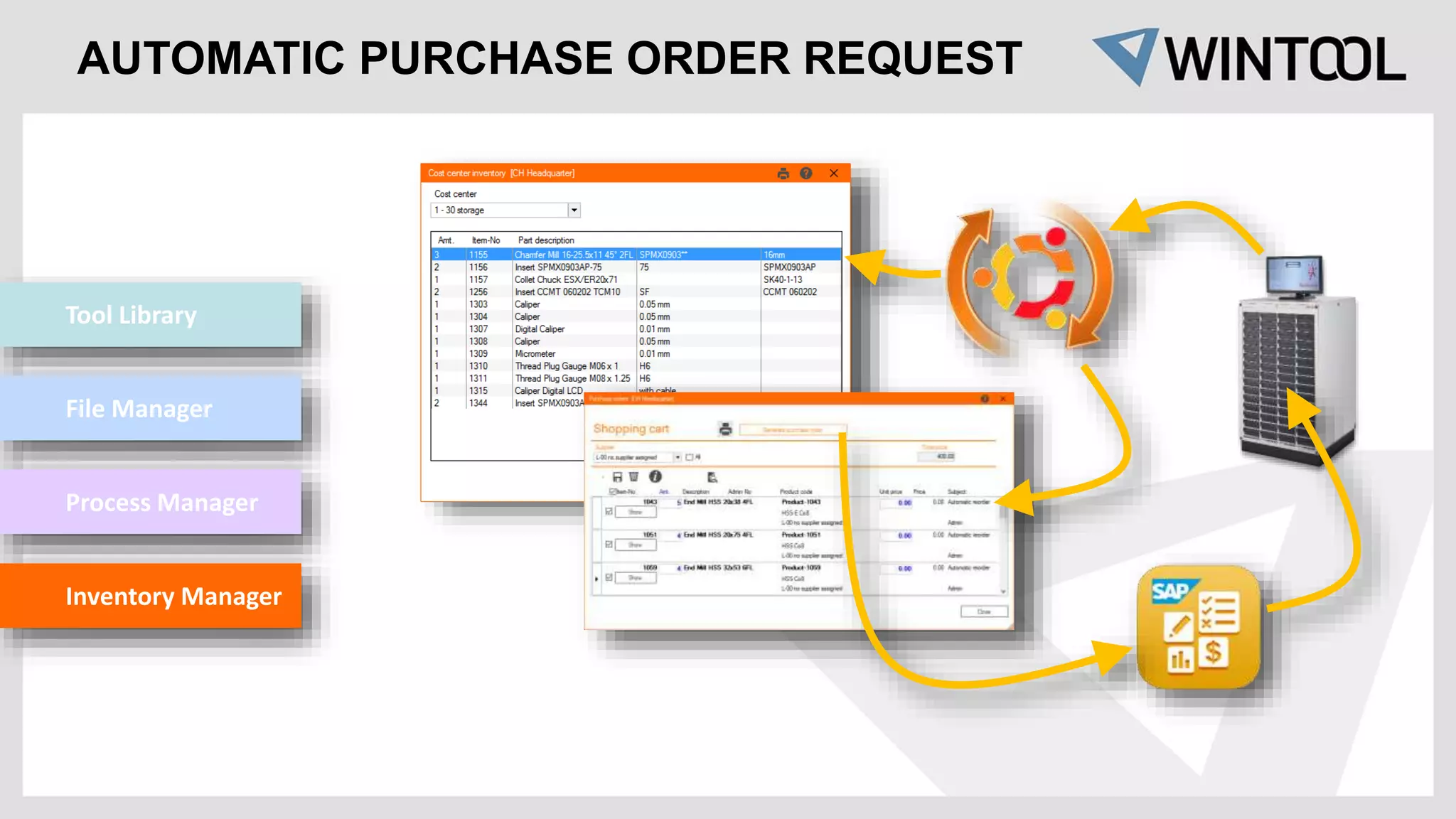

Purchasing: Tool Procurement Total per Year WinTool process improvements Potential savings

Tool orders per month 50

1 h 50% 30 min 15’000 €

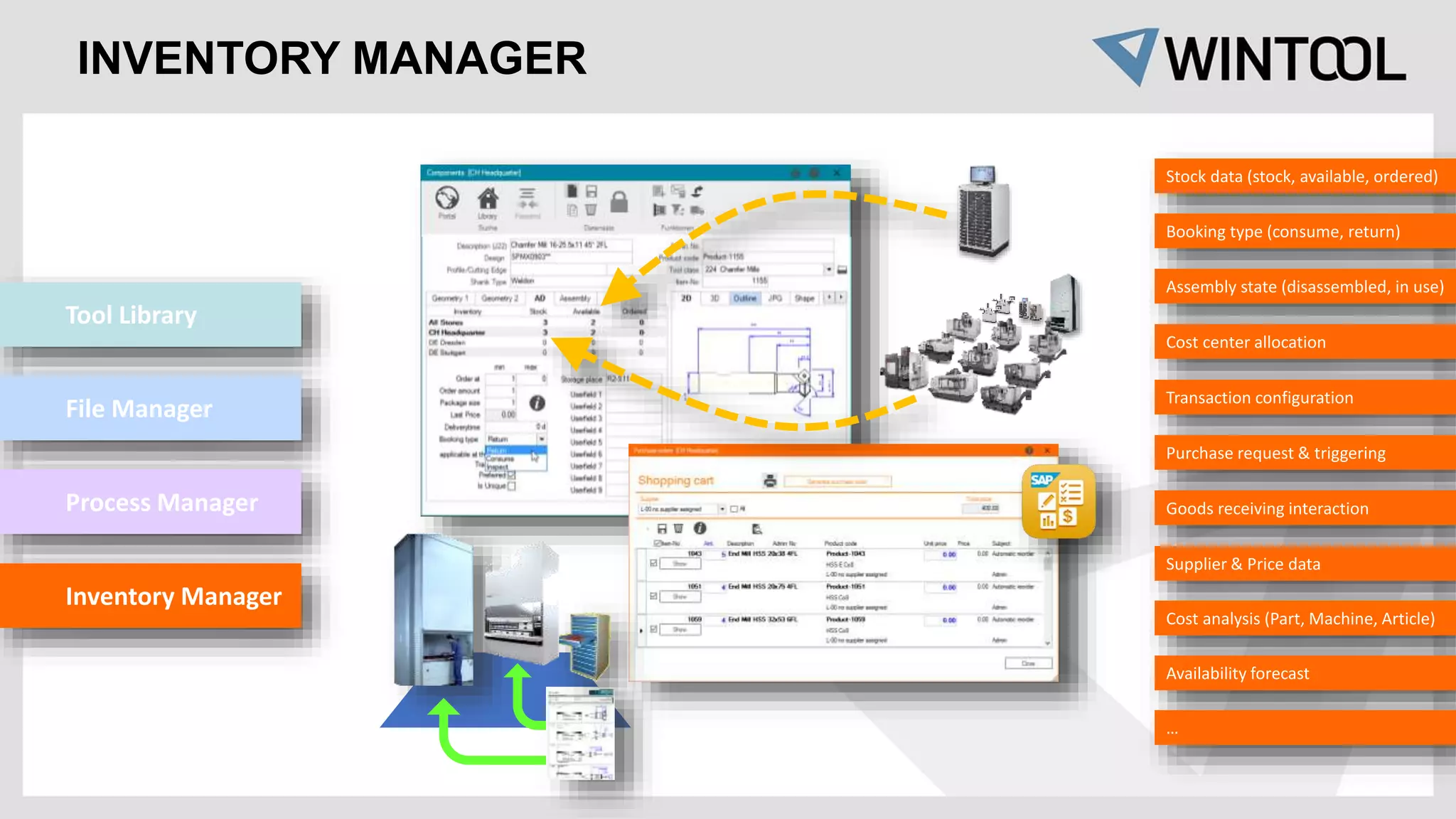

Storage: Tool Storage & Retrieval Total per Year WinTool process improvements Potential savings

Tool movements per month 1000