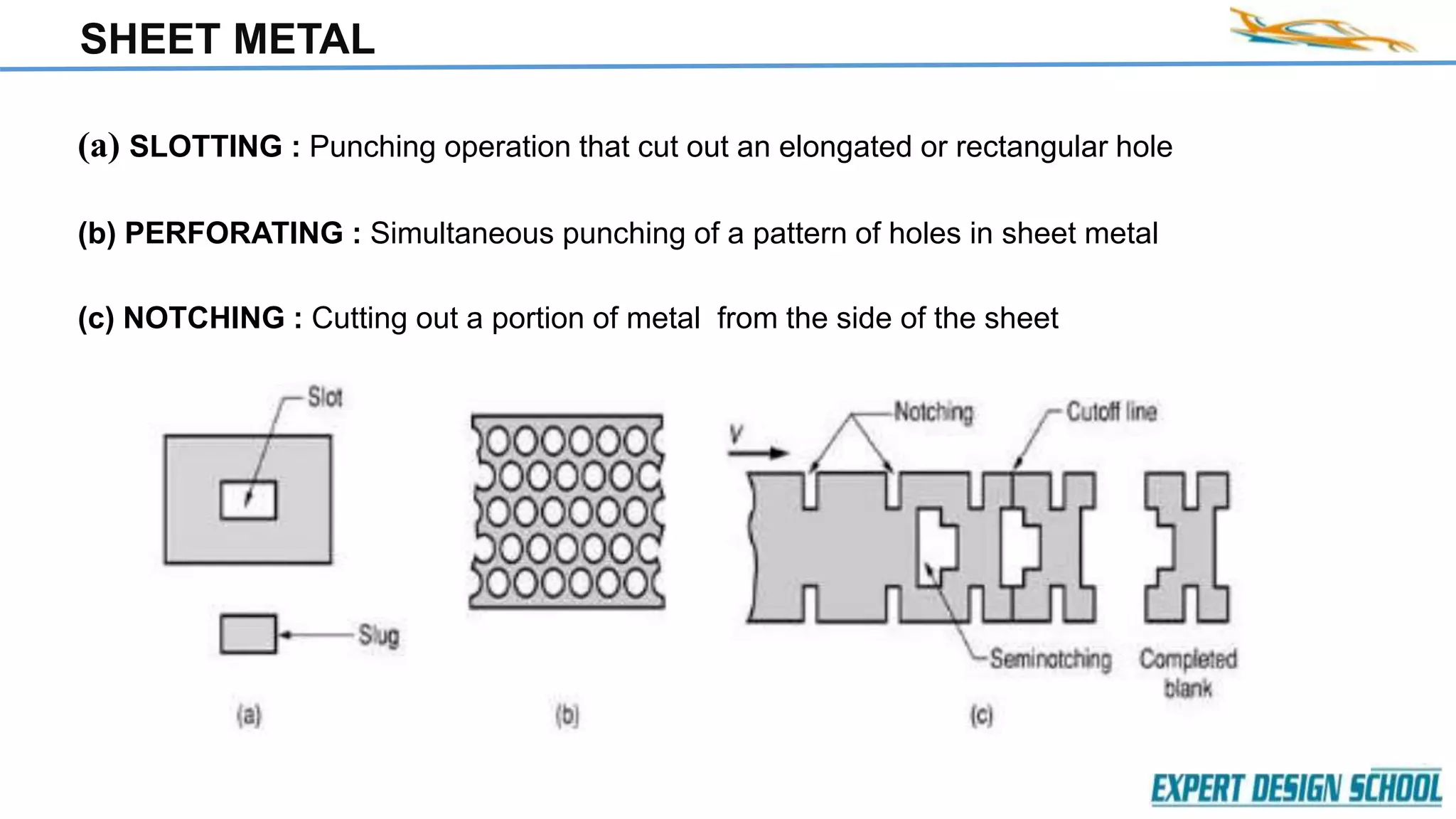

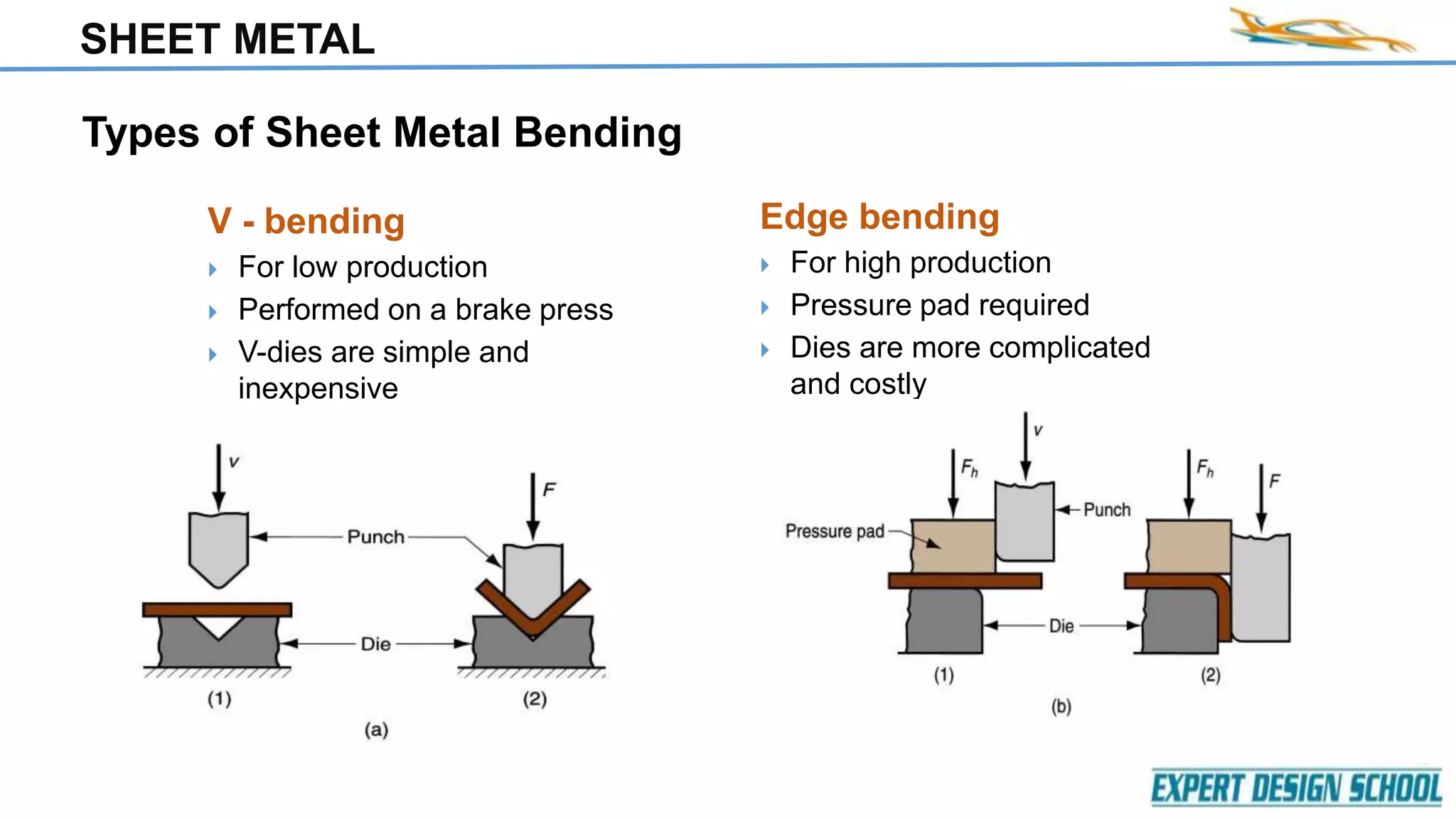

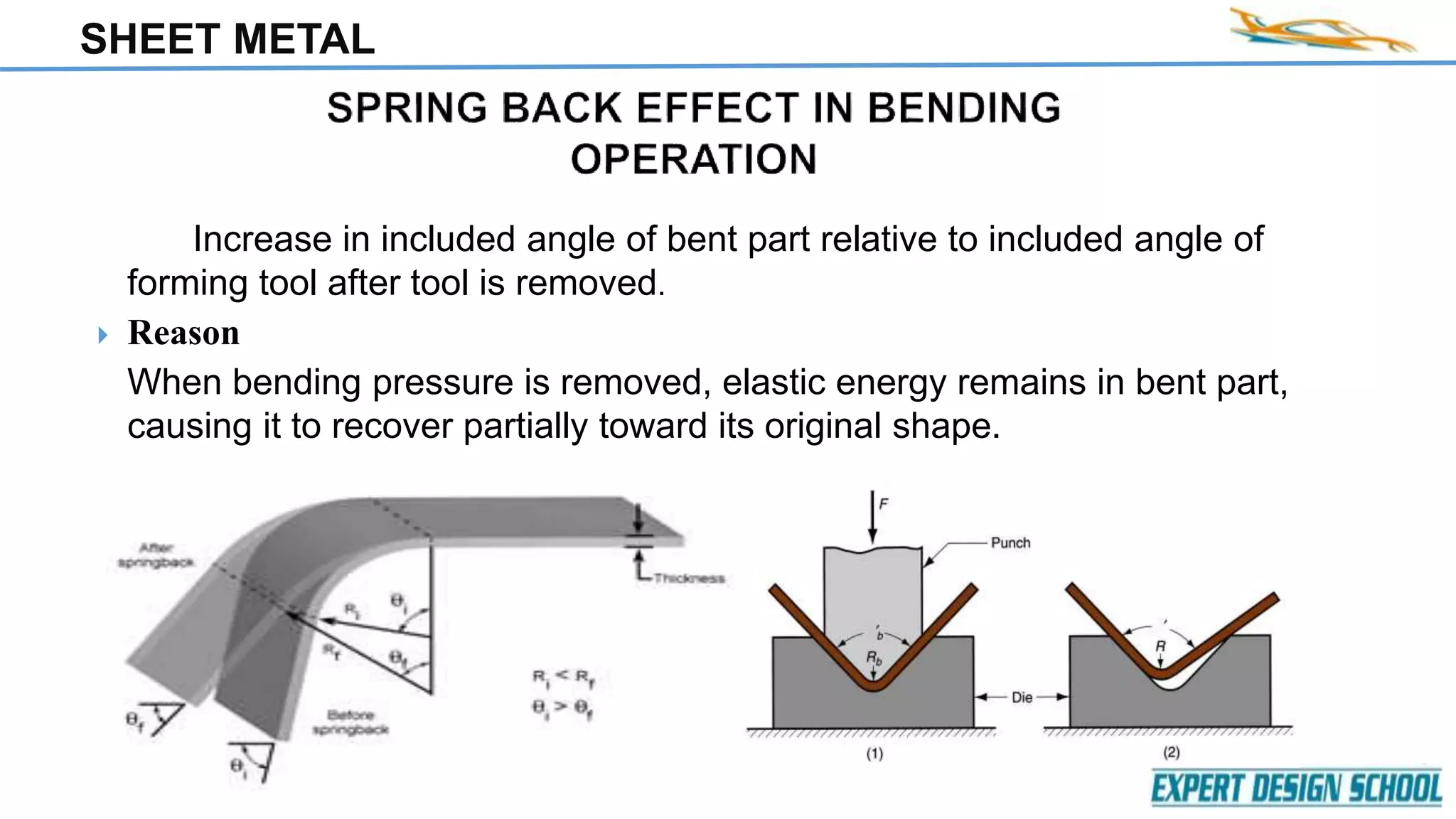

This document provides an overview of sheet metal, including its design, common materials, applications, and processing techniques such as shearing, bending, and drawing. It outlines factors affecting sheet metal design, such as tolerances, spacing between holes, and welding methods. Additionally, it details standard sizes and classification of sheet metal based on thickness and gauge sizes.