This paper presents the design, optimization, and simulation of plastic toy building blocks using mold flow analysis to mitigate issues like shrinkage, weld lines, and air traps. It highlights the effectiveness of Autodesk Moldflow software in optimizing injection molding processes by reducing costs and trial-and-error methods. The study investigates various factors affecting production cycles and quality, ensuring optimal design parameters for enhanced manufacturability.

![Injection Molding Methods Design, Optimization, Simulation of Plastic Toy Building Block by Mold Flow

Analysis, Manmit Salunke, Rushikesh Kate, Vishwas Lomate, Gajanan Sopal, Journal Impact Factor (2015):

8.8293 Calculated by GISI (www.jifactor.Com)

www.iaeme.com/ijmet.asp 41 editor@iaeme.com

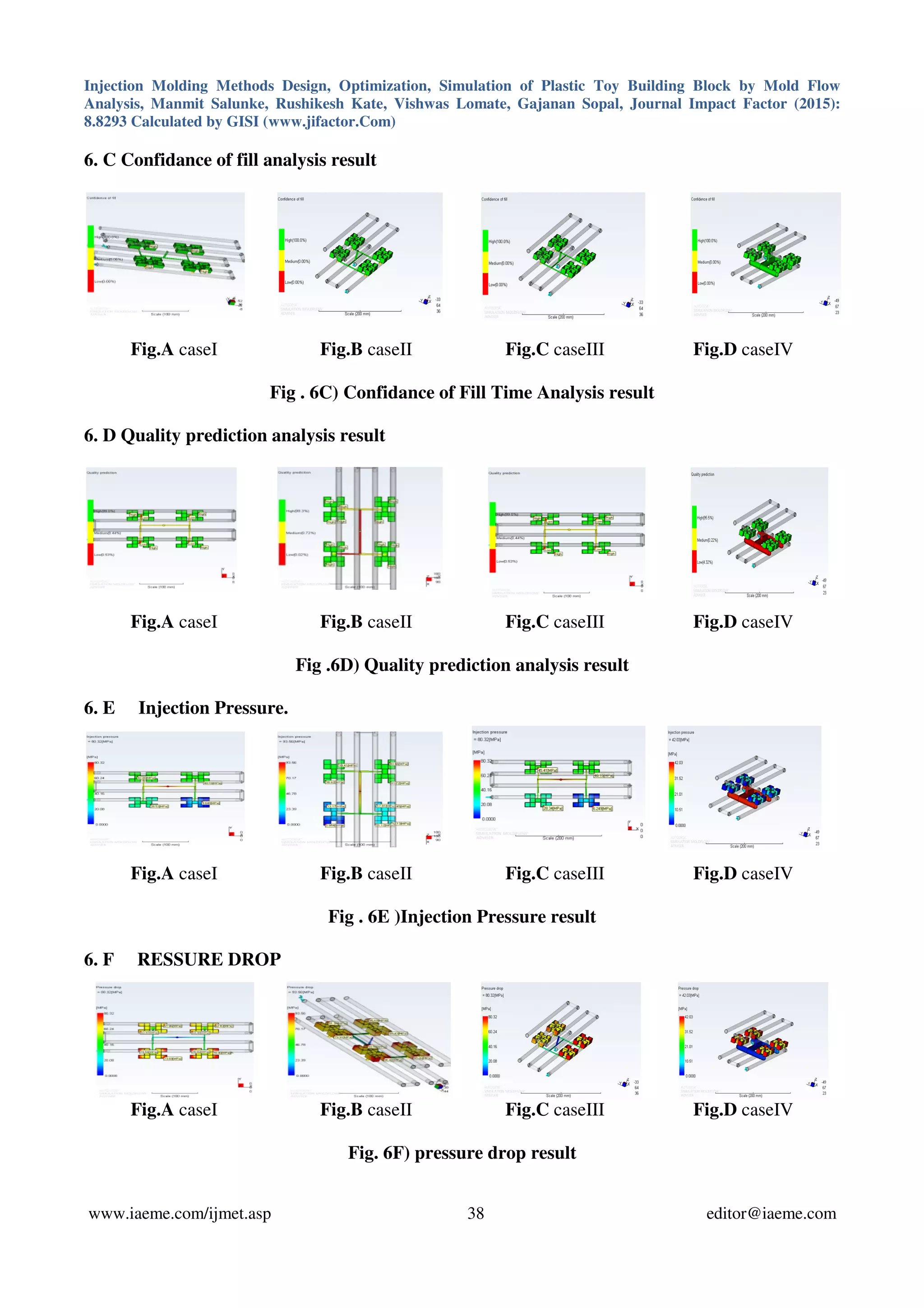

Cooling Quality

Maximum and minimum temperature

variance 5.1 C & -1.2 C

7.8 (C) (C) & -

7.4 C

5.1 (C) & -2.5

(C) 7.3 (C) & -9.5 C

Maximum and minimum cooling time

variance

0.49 (s) & -

0.57 (s)

1.47 (s) & -1.19

(s)

0.49 (s) & -0.57

(s)

1.65 (s) &-1.25

(s)

Cool tab

Maximum temperature, part 49.2 (C) 49.4 c 49.3 (C) 53.5 c

Minimum temperature, part 32.6 (C) 32.5 c 32.6 (C) 34.7 c

Average temperature, part 41.1 (C) 40.9 c 41.1 (C) 45.2 c

Mold exterior temperature 27.4 (C) 27.3 c 27.4 (C) 28.6 (C)

The comparison of initial and modified designs on various parameters

1) Considering initial design for plasic toy, 2mm thikness at moddle cavity, simulation result

showing cooling time of part not uniform and have very high value .Fill analysis shows poor

quality for part. So model is redesigned for unform wall thiknes 1mm .Then simulation result

shows better quality of part.

2) After fill analysis shows part have lower quality for LDPE material and high quality for ABS

material .Different four cases of runner sprue and gate system are analyzed by using ABS

material for plasic toy.

3) In case IV have large filling time and more runner system volume so wastage of material is

high. Case II have lower filling time but more shrinkage.

4) Case I have lower cycle time, high confidence of fill, high quality. So have good optimum

design solution for defect free part.

8. CONCLUSION

The filling time and the cooling time of a four cavity design does not increase to four

times longer than having a single cavity. So the cycle time for four cavities design is the most

optimum and efficient to be used in the production process. The analysis work shows the parameters

such as sink marks, fill time, weld line, air traps etc. that will affects the quality of the finished

product. Plastic Flow Simulation Simulate the flow of melted plastic to help optimize part and mold

designs, reduce potential part defects, and improve the molding process and decrease the cycle time

and to improve the Quality of the Product.

REFERENCE

1. Auto desk Mold-Flow Insight material data warehouse.

2. wikimedia Foundation, Inc, 2010. InjectionMoulding. [online] Available at: <http://en.

wikipedia. org/wiki/Injection_moulding> [Accessed 28 August 2010]

3. Bryce, D. M., ‘Plastic injection molding: Manufacturing process fundamental’. Society of

Manufacturing Engineers, (1996)

4. Sri. P V S M Varma and Sri. P N E Naveen, “Optimizing Injection Moulding Tool Cost by

Using Virtual Software Techniques” International Journal of Mechanical Engineering &

Technology (IJMET), Volume 4, Issue 6, 2013, pp. 227 - 240, ISSN Print: 0976 – 6340,

ISSN Online: 0976 – 6359](https://image.slidesharecdn.com/injection-molding-methods-design-optimization-simulation-of-plastic-toy-building-block-by-mold-flow--160216122136/75/Injection-molding-methods-design-optimization-simulation-of-plastic-toy-building-block-by-mold-flow-analysis-9-2048.jpg)

![Injection Molding Methods Design, Optimization, Simulation of Plastic Toy Building Block by Mold Flow

Analysis, Manmit Salunke, Rushikesh Kate, Vishwas Lomate, Gajanan Sopal, Journal Impact Factor (2015):

8.8293 Calculated by GISI (www.jifactor.Com)

www.iaeme.com/ijmet.asp 42 editor@iaeme.com

5. Mr. A.B. Humbe and Dr. M.S. Kadam, “Optimization of Process Parameters of Plastic

Injection Molding For Polypropylene To Enhance Productivity and Reduce Time For

Development” International Journal of Mechanical Engineering & Technology (IJMET),

Volume 5, Issue 5, 2014, pp. 157 - 169, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359

6. Mr. A.B. Humbe and Dr. M.S. Kadam, “Optimization of Critical Processing Parameters For

Plastic Injection Molding of Polypropylene For Enhanced Productivity and Reduced Time

For New Product Development” International Journal of Mechanical Engineering &

Technology (IJMET), Volume 5, Issue 1, 2014, pp. 108 - 115, ISSN Print: 0976 – 6340,

ISSN Online: 0976 – 6359

7. Moldflow Plastic Insight, 2014. Moldflow Tutorial. [Software tutorial] Mold-flow

Corporation

8. Tang, S.H., Kong, Y.M.,Sapuan, S.M., Samin, R., and Sulaiman, S., “Design and thermal

analysis of plastic injection mold” , Journal of Materials Processing Technology, Vol. 171,

pp. 259-267, 2006.

9. http://www.engineersedge.com/injection_molding,.htm, 2006

10. http://www.efunda.com/DesignStandards/plastic_design/plastic_intro.cfm, 2006](https://image.slidesharecdn.com/injection-molding-methods-design-optimization-simulation-of-plastic-toy-building-block-by-mold-flow--160216122136/75/Injection-molding-methods-design-optimization-simulation-of-plastic-toy-building-block-by-mold-flow-analysis-10-2048.jpg)