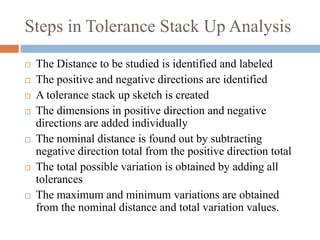

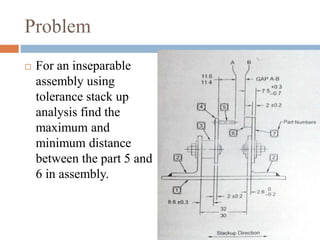

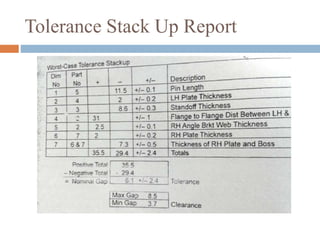

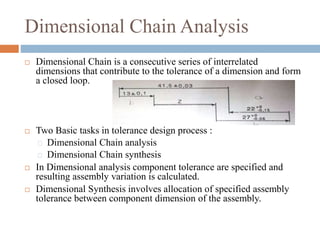

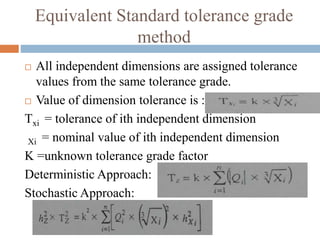

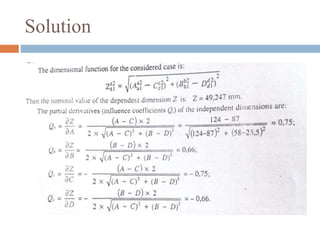

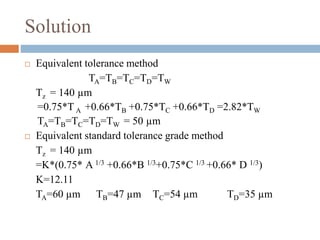

This document discusses tolerance stack up analysis which determines the maximum possible variation between components in an assembly. It describes the merits of tolerance stack up analysis such as optimizing part tolerances. The key steps are identified including labeling dimensions, creating a sketch, adding dimensions, finding nominal and total variation. An example problem is provided to find the maximum and minimum distance between parts using a tolerance stack up report and sketch. Dimensional chain analysis and synthesis are also overviewed. Equivalent tolerance and standard tolerance grade methods are explained for solving tolerance allocation problems.