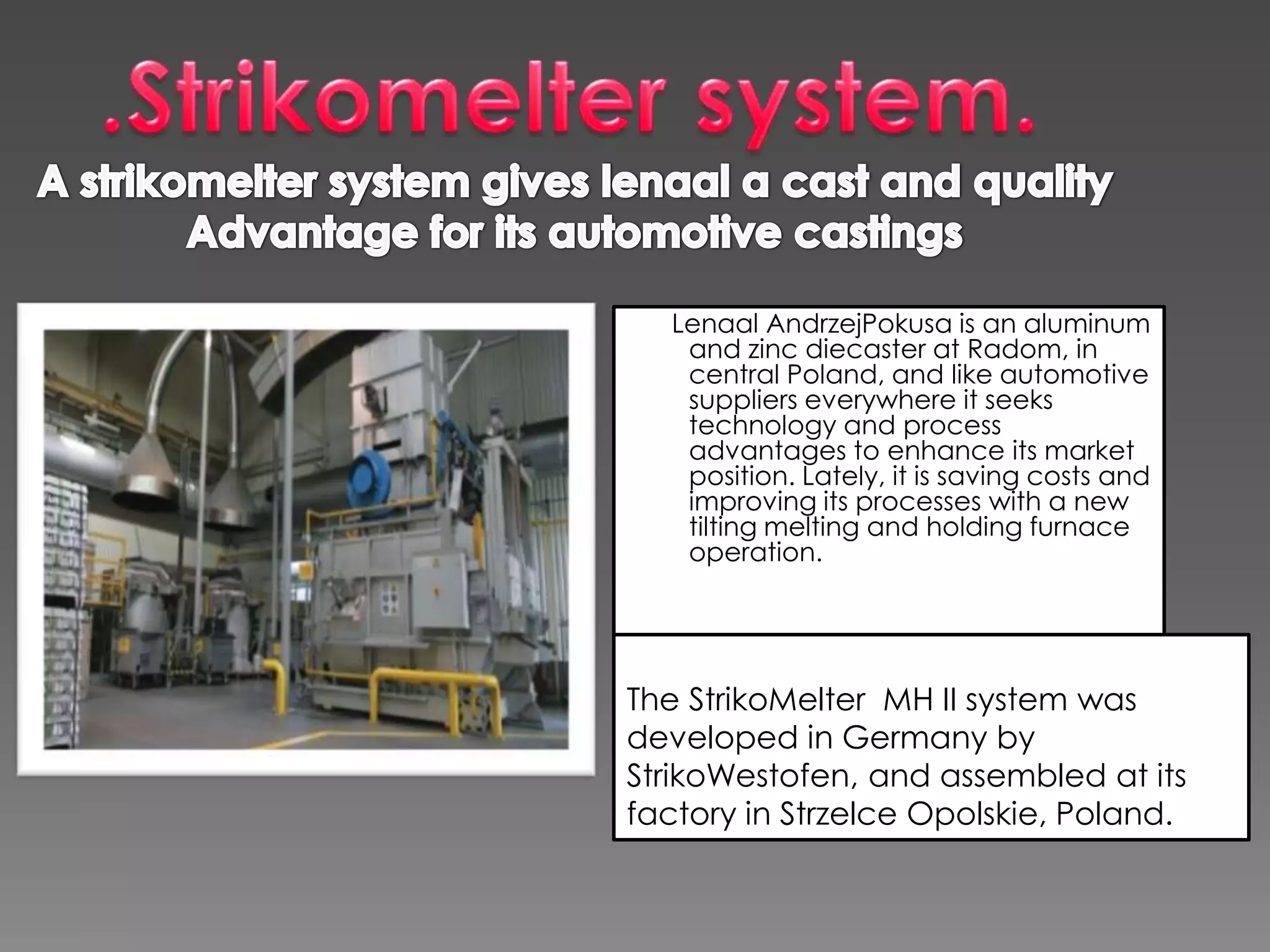

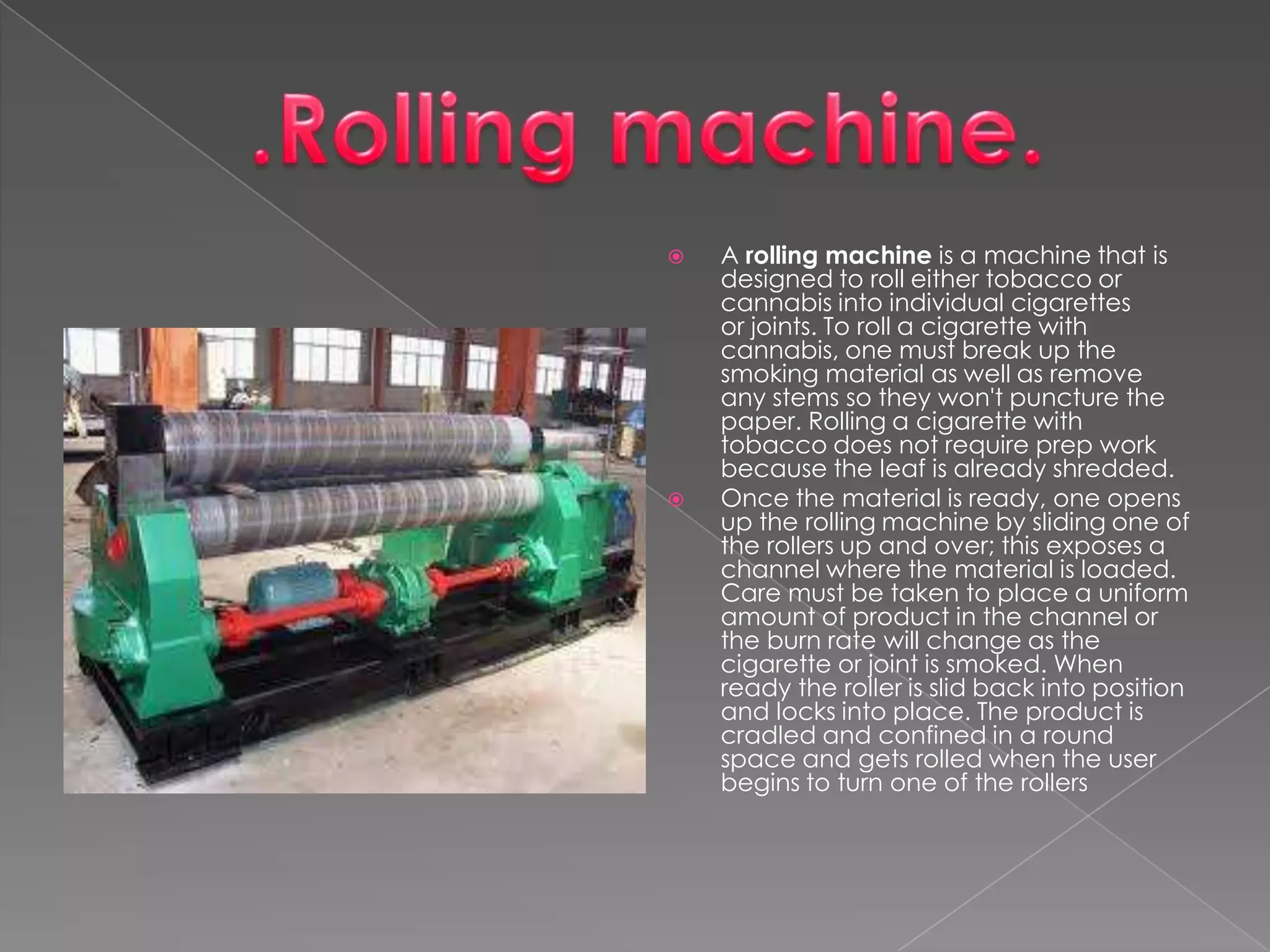

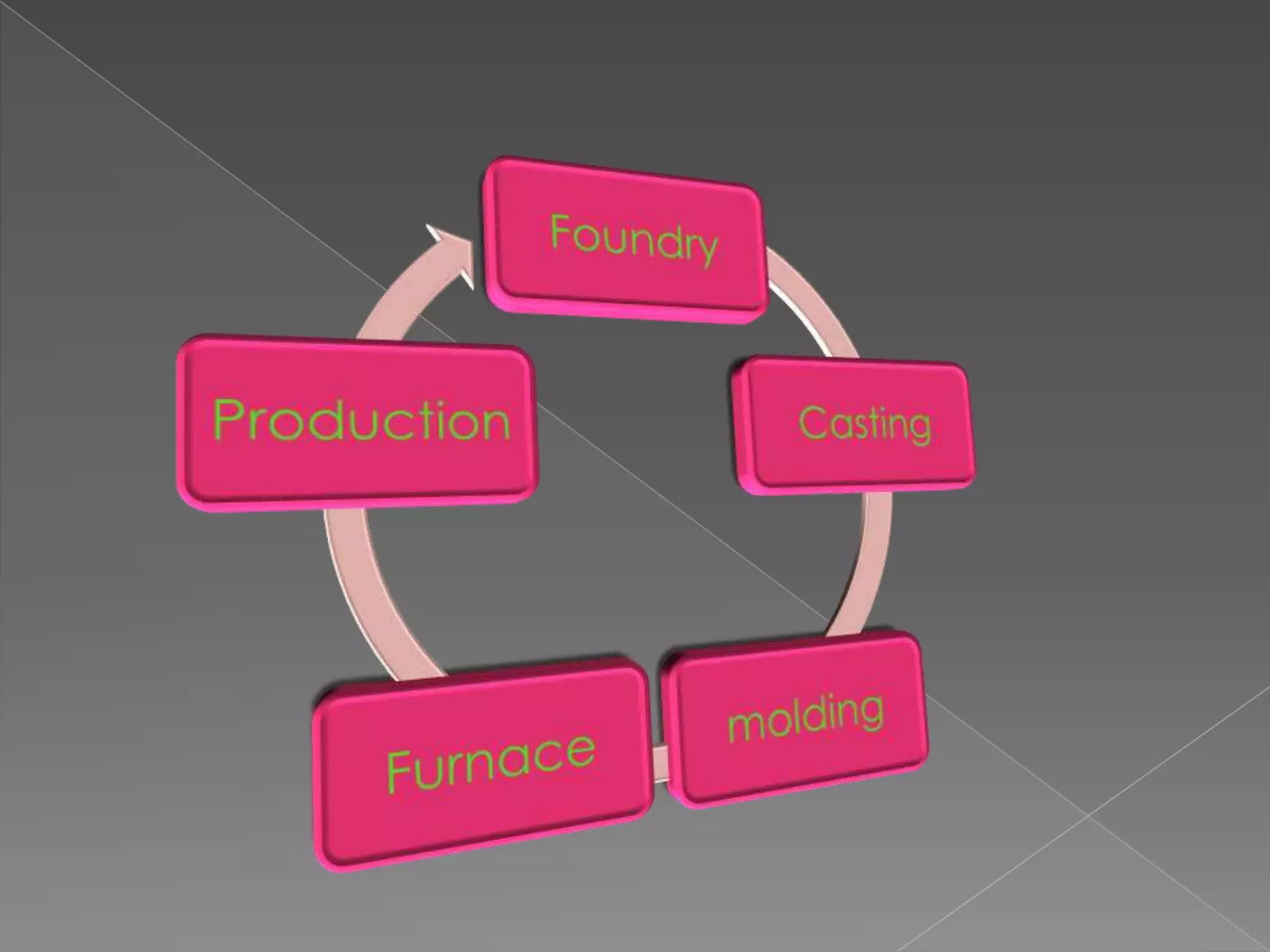

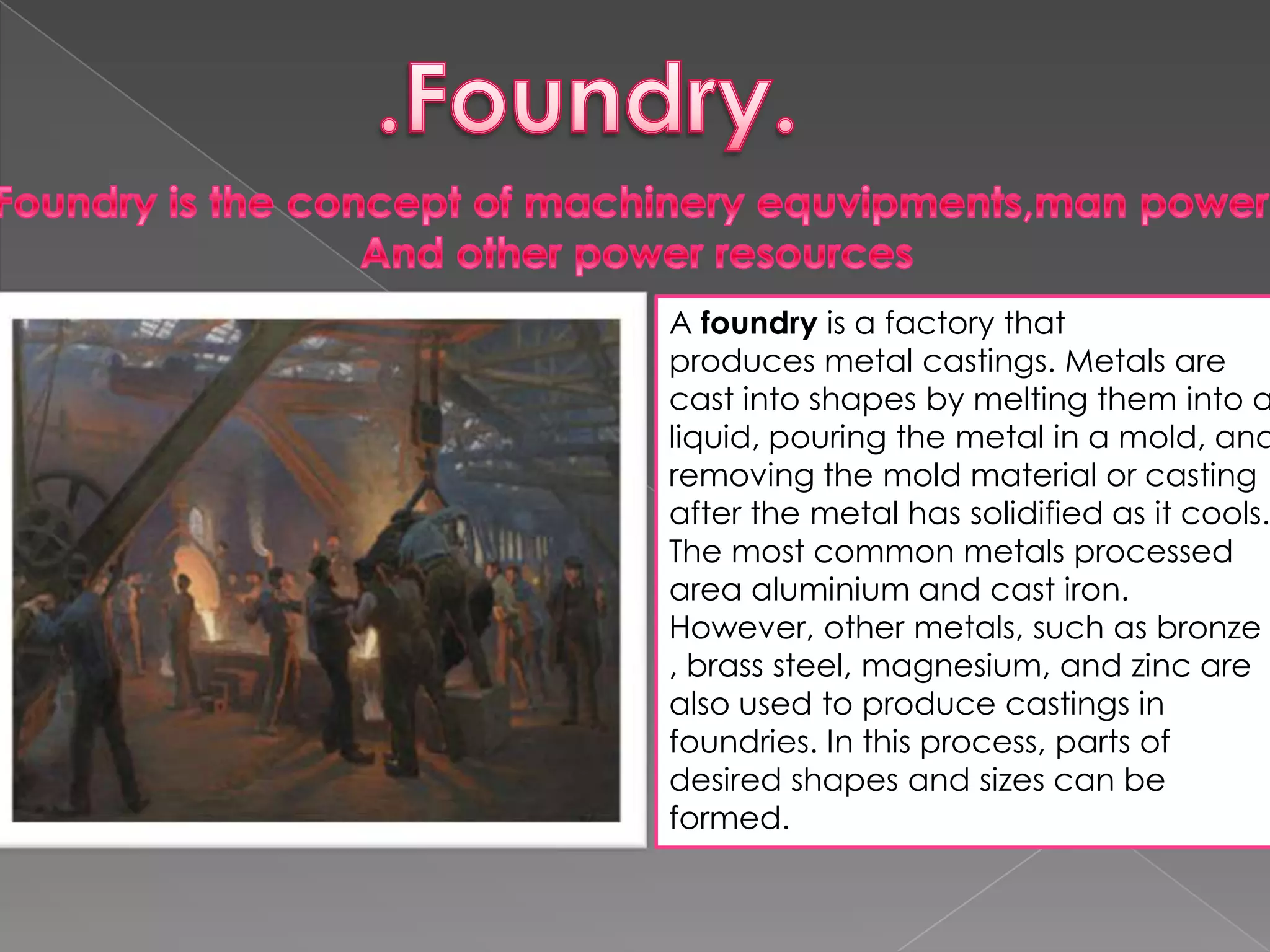

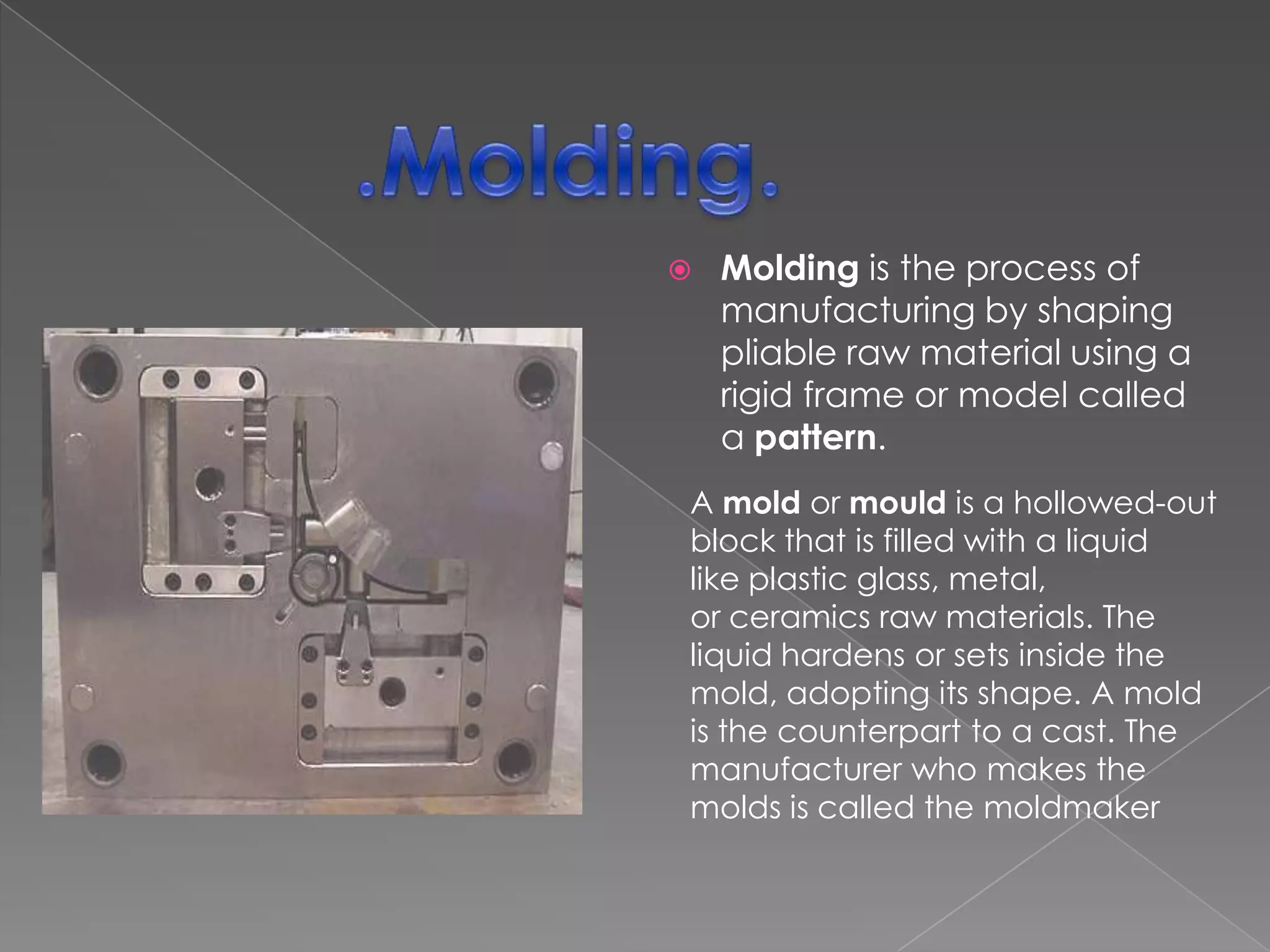

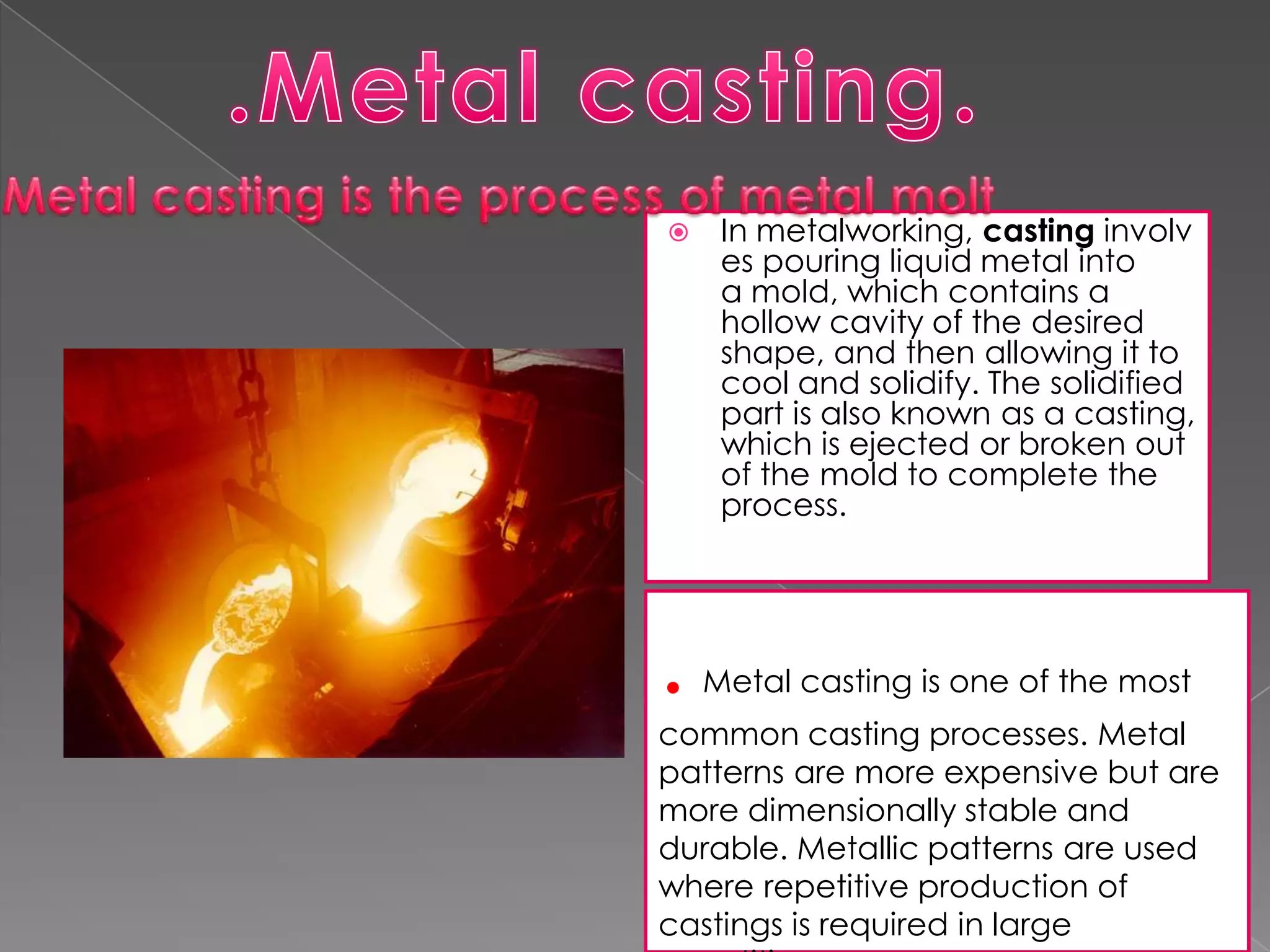

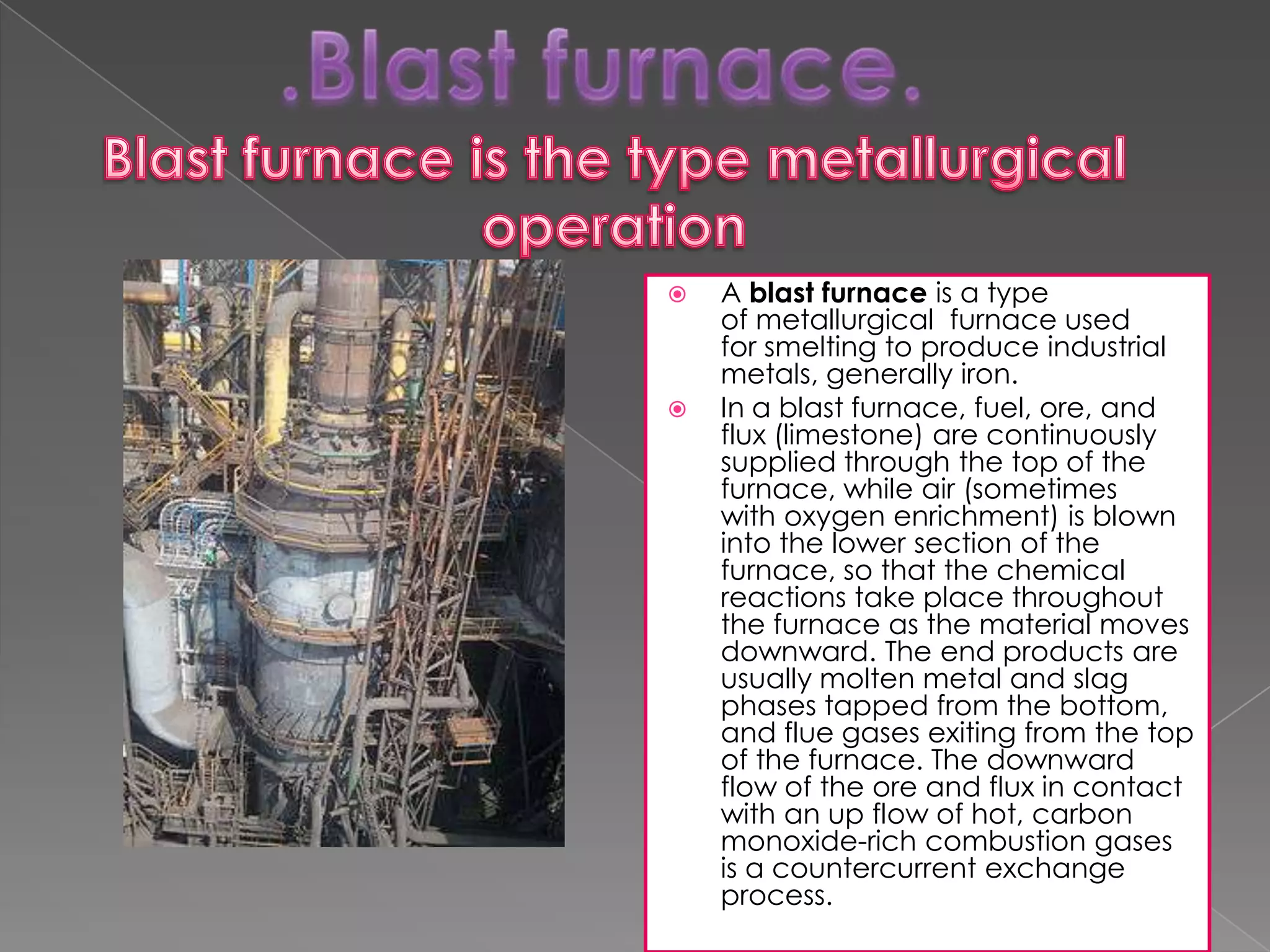

A foundry produces metal castings using molds. Metals are melted and poured into molds, then allowed to solidify. Common metals cast include aluminum and iron. Molding involves shaping materials using molds. Molds are hollow blocks that materials like plastic or metal are poured into to adopt the mold shape. New technologies have improved foundries by reducing costs, labor, and space needs while improving productivity.

![Foundry consist machinery , man power ,

advance technology etc.

Foundry contain mainly metal casting ,

furnace ,molding and other

process[production]

After all of that,

New technologies and techniques enter

in foundry and factories.

](https://image.slidesharecdn.com/newtrendsinfoundrytechnologiesautosaved-140221052924-phpapp01/75/New-trends-in-foundry-technologies-3-2048.jpg)

![When different techniques and

technologies entered in factory then lot

of benefits are creates for all of us.

1.less work

2.less time

3.less money [low cost machine]

4.less man power

5.more ways of earning

6.good productivity

](https://image.slidesharecdn.com/newtrendsinfoundrytechnologiesautosaved-140221052924-phpapp01/75/New-trends-in-foundry-technologies-10-2048.jpg)