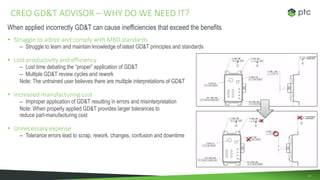

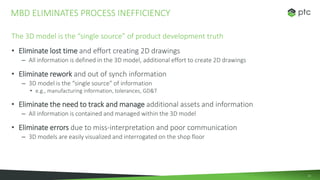

This document discusses model-based definition (MBD) and the benefits it provides over traditional 2D drawing-based processes. It notes that MBD, by capturing all product information within a 3D model, eliminates inefficiencies in traditional processes where 2D drawings must be created and kept in sync with 3D models. It then highlights how the Creo GD&T Advisor extension helps users more easily create and validate geometrical dimensioning and tolerancing information within models, improving compliance with MBD standards and reducing errors. Key industries that are leading adoption of MBD like aerospace, defense, and automotive are mentioned.