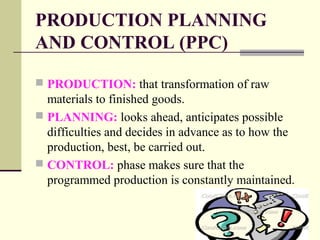

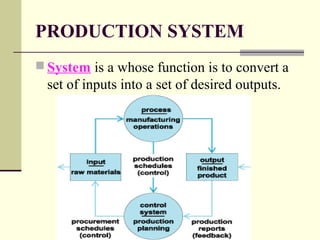

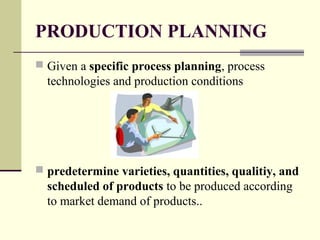

This document discusses production planning and control (PPC). It defines PPC as the process of planning production in advance of operations, establishing the production route for each item, and initiating follow up and corrective measures. It describes the key aspects of PPC including production planning, control, scheduling, loading, routing, dispatching, follow up, inspection and corrective actions. It also provides an overview of material requirements planning (MRP) and its aims to renew inventory levels and meet customer orders.