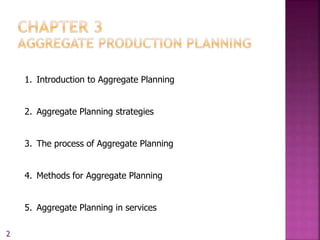

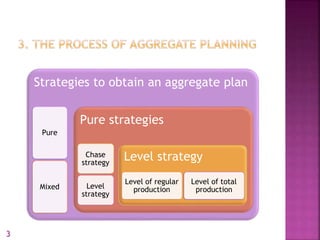

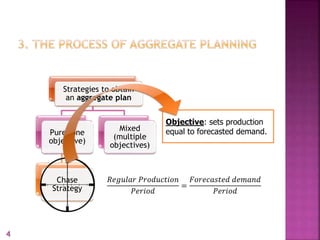

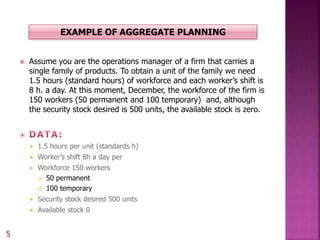

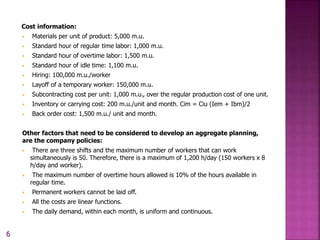

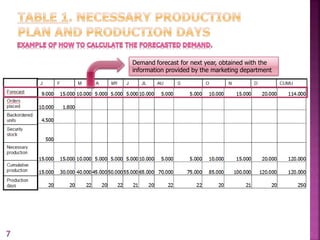

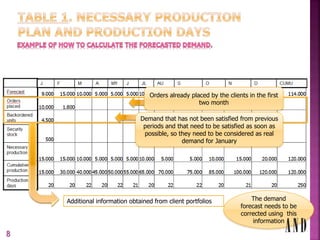

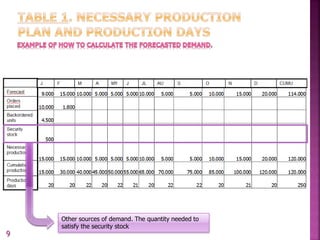

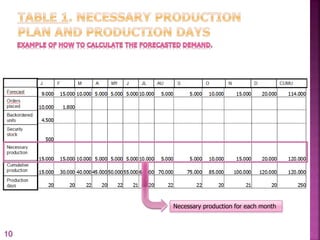

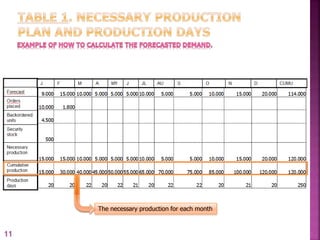

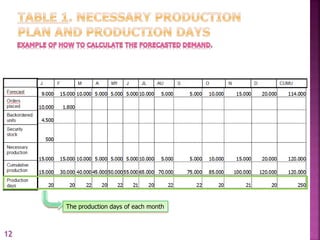

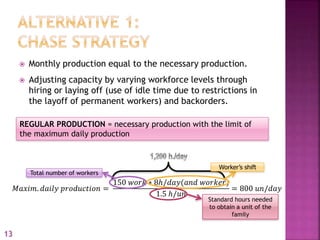

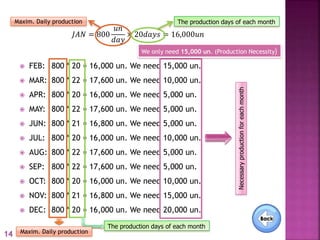

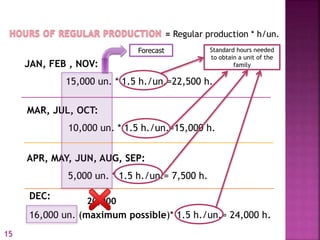

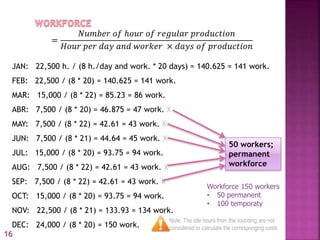

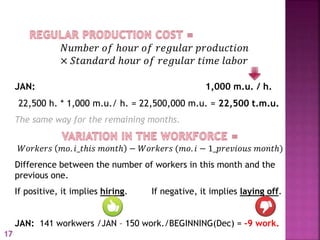

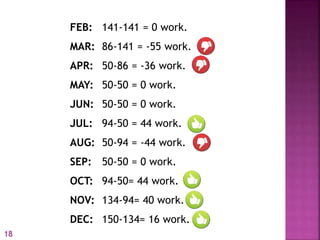

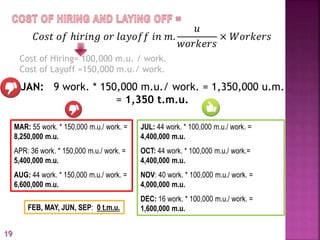

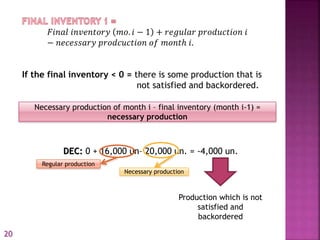

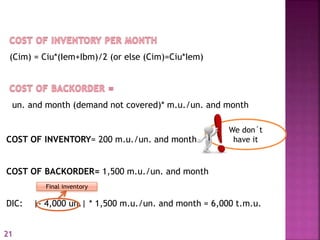

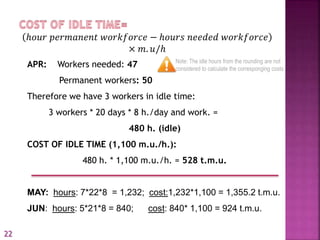

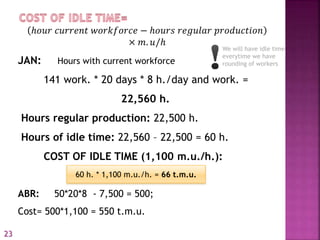

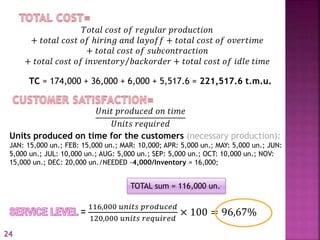

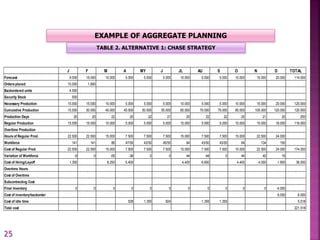

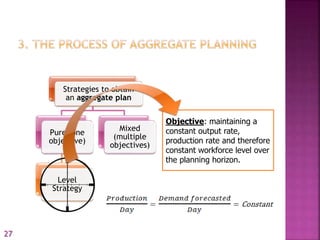

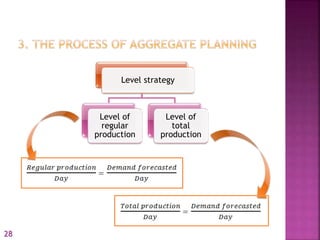

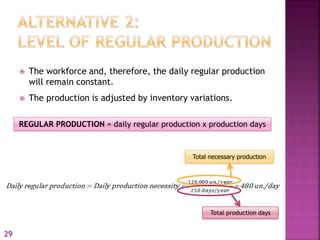

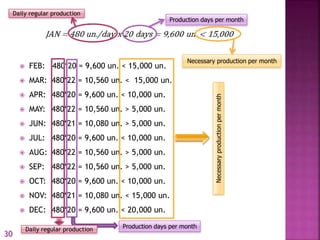

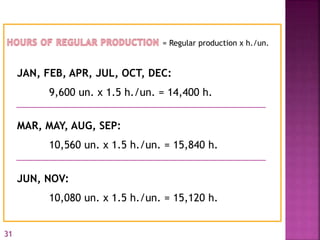

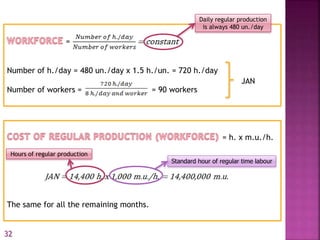

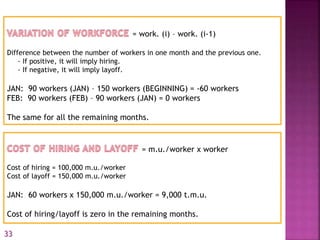

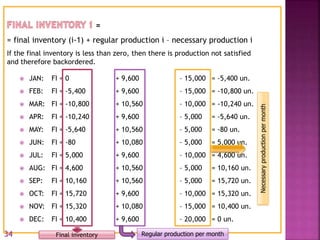

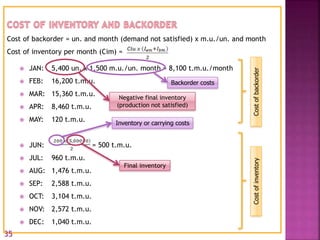

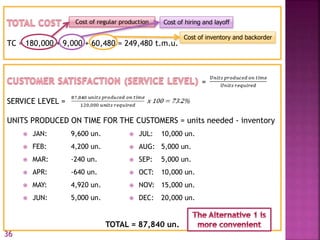

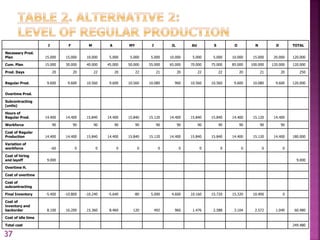

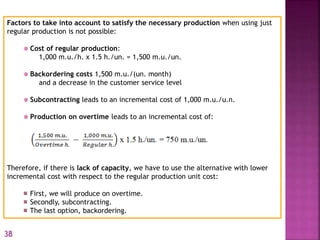

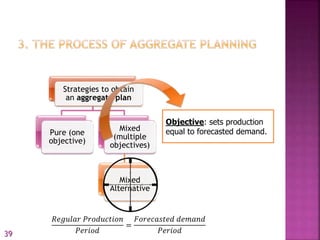

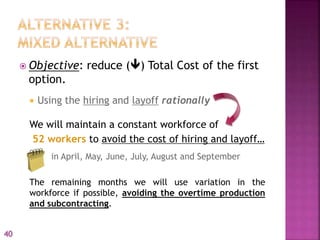

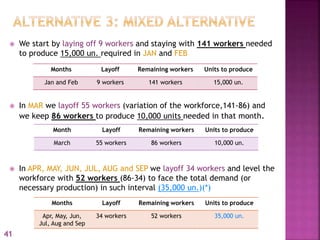

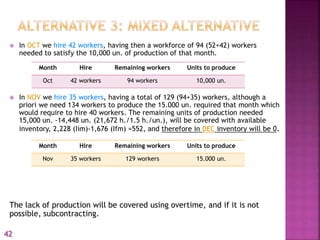

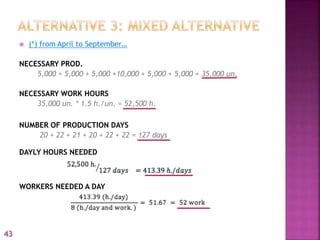

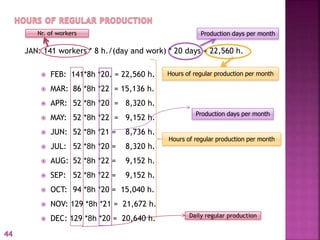

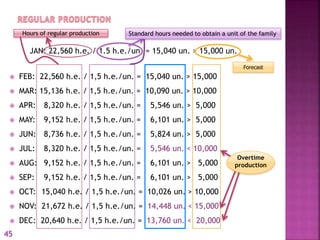

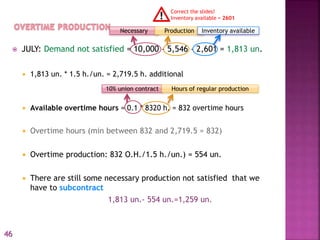

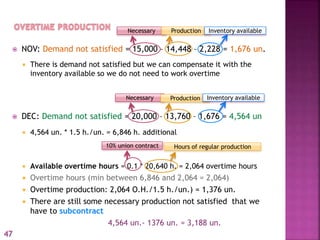

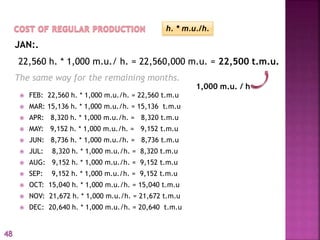

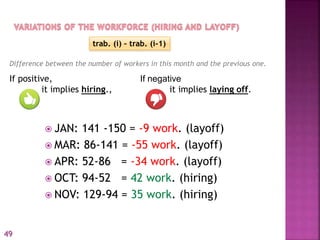

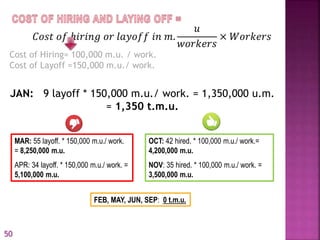

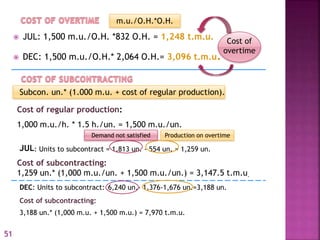

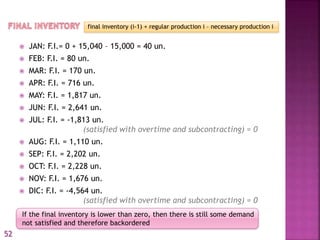

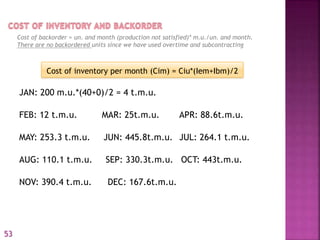

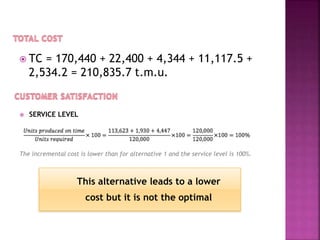

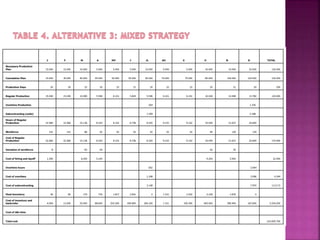

This document discusses aggregate planning strategies and methods. It provides an example of how to develop an aggregate production plan for a firm over a one-year period. Key steps include forecasting demand, determining necessary production levels, calculating regular production levels based on workforce capacity, adjusting workforce levels through hiring and layoffs, and calculating associated costs of production, inventory, backorders, and idle time. The example shows calculations for each month to develop an optimal aggregate production plan that meets demand while minimizing total costs over the planning period.