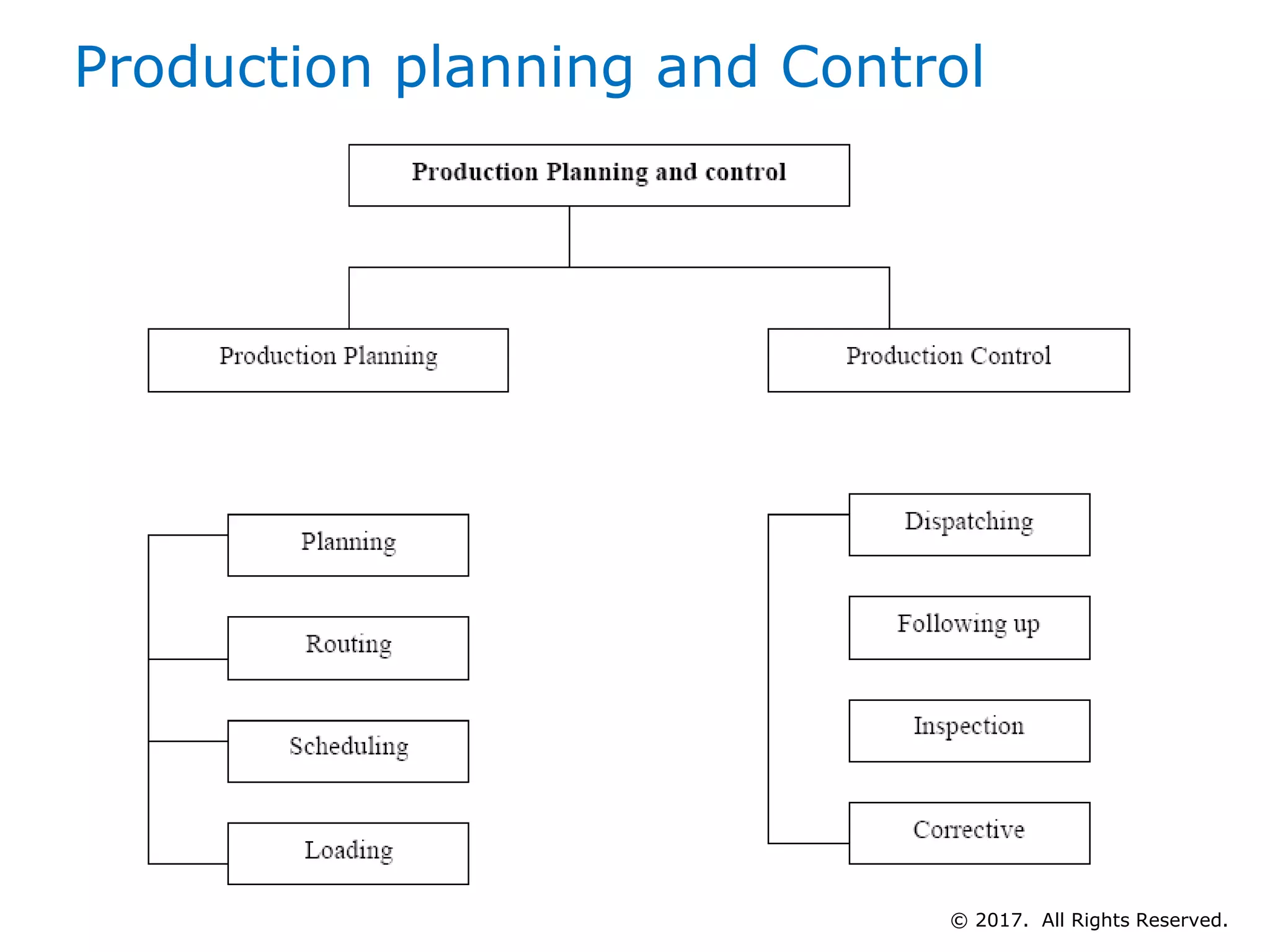

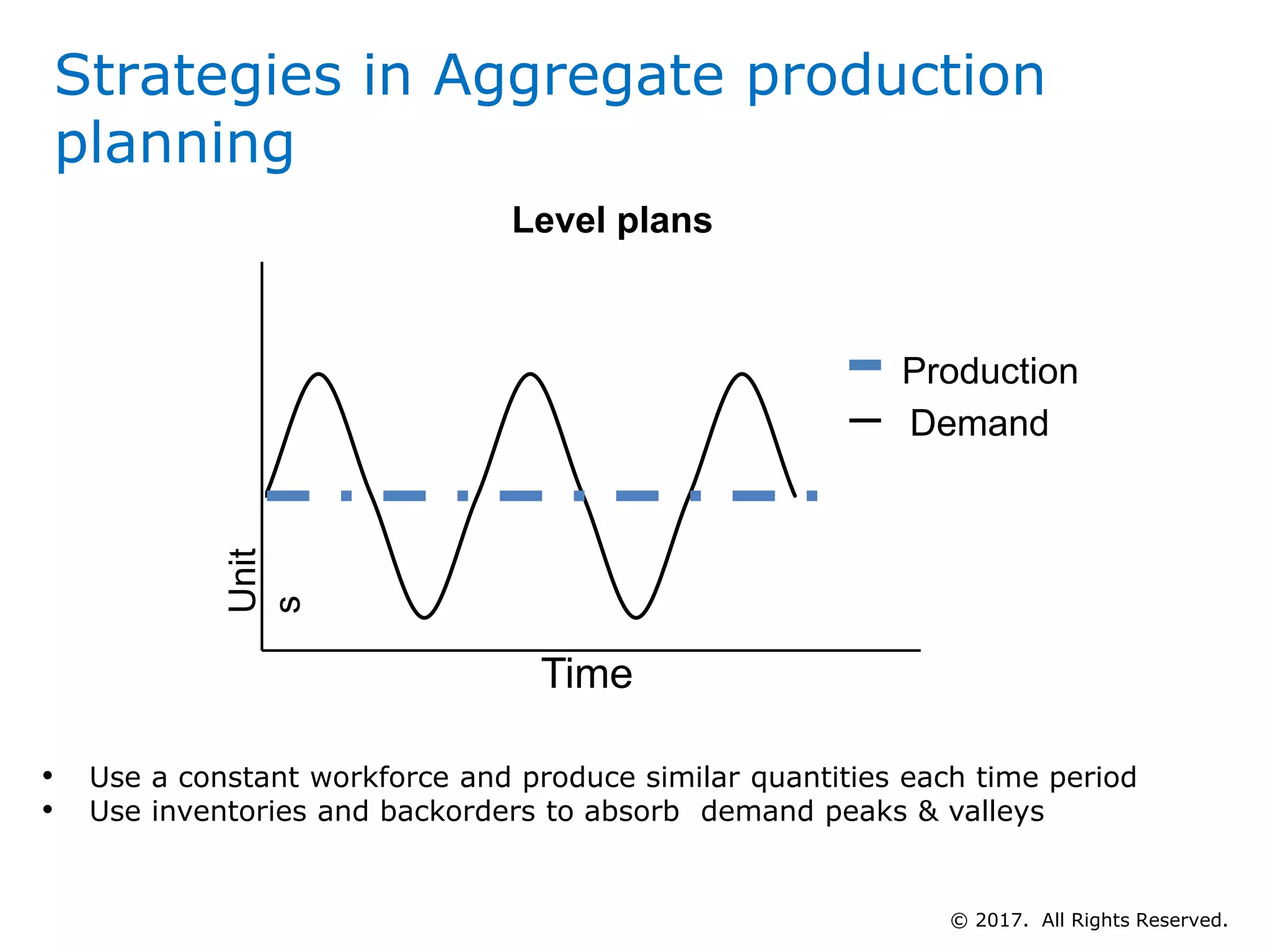

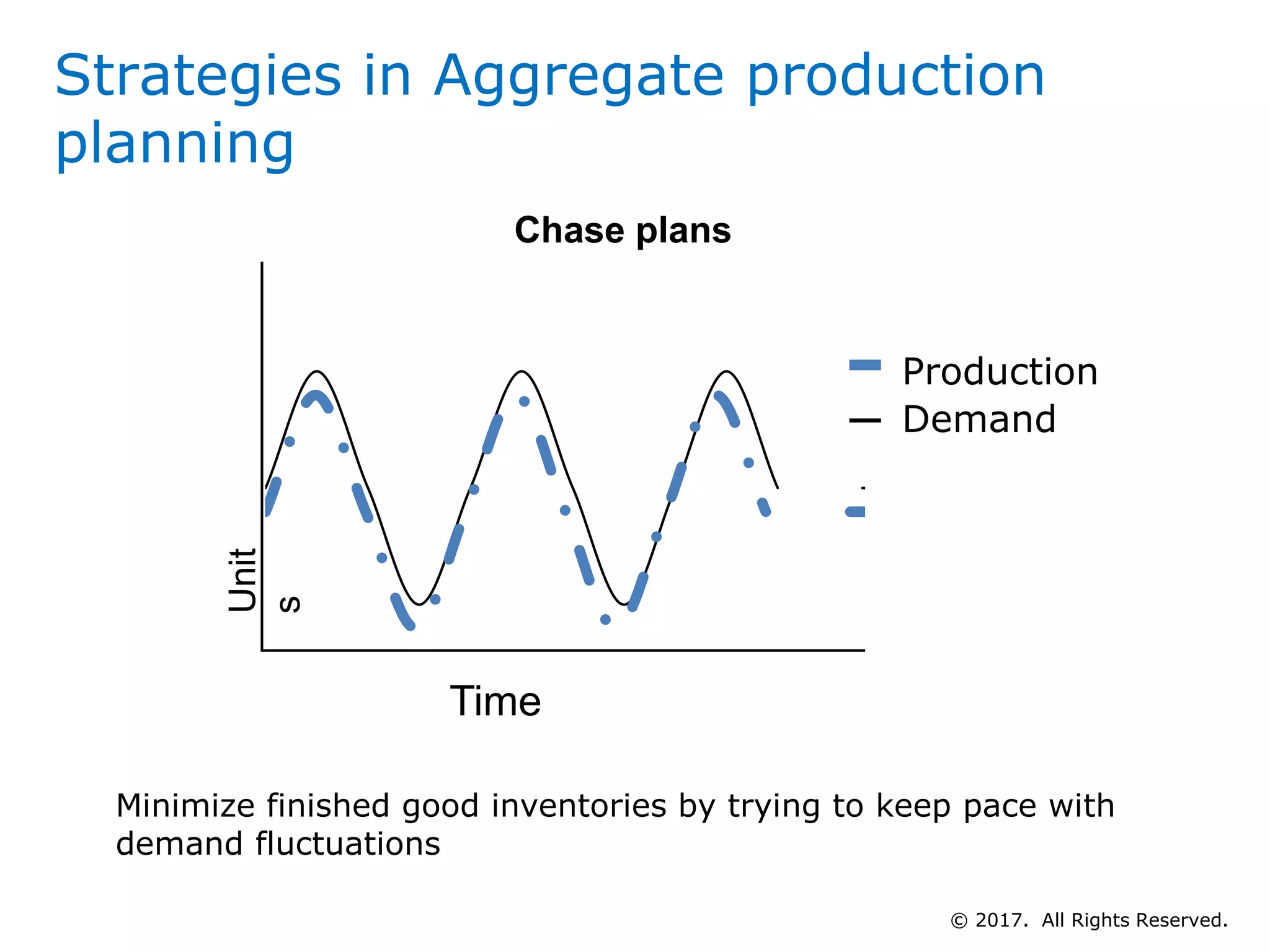

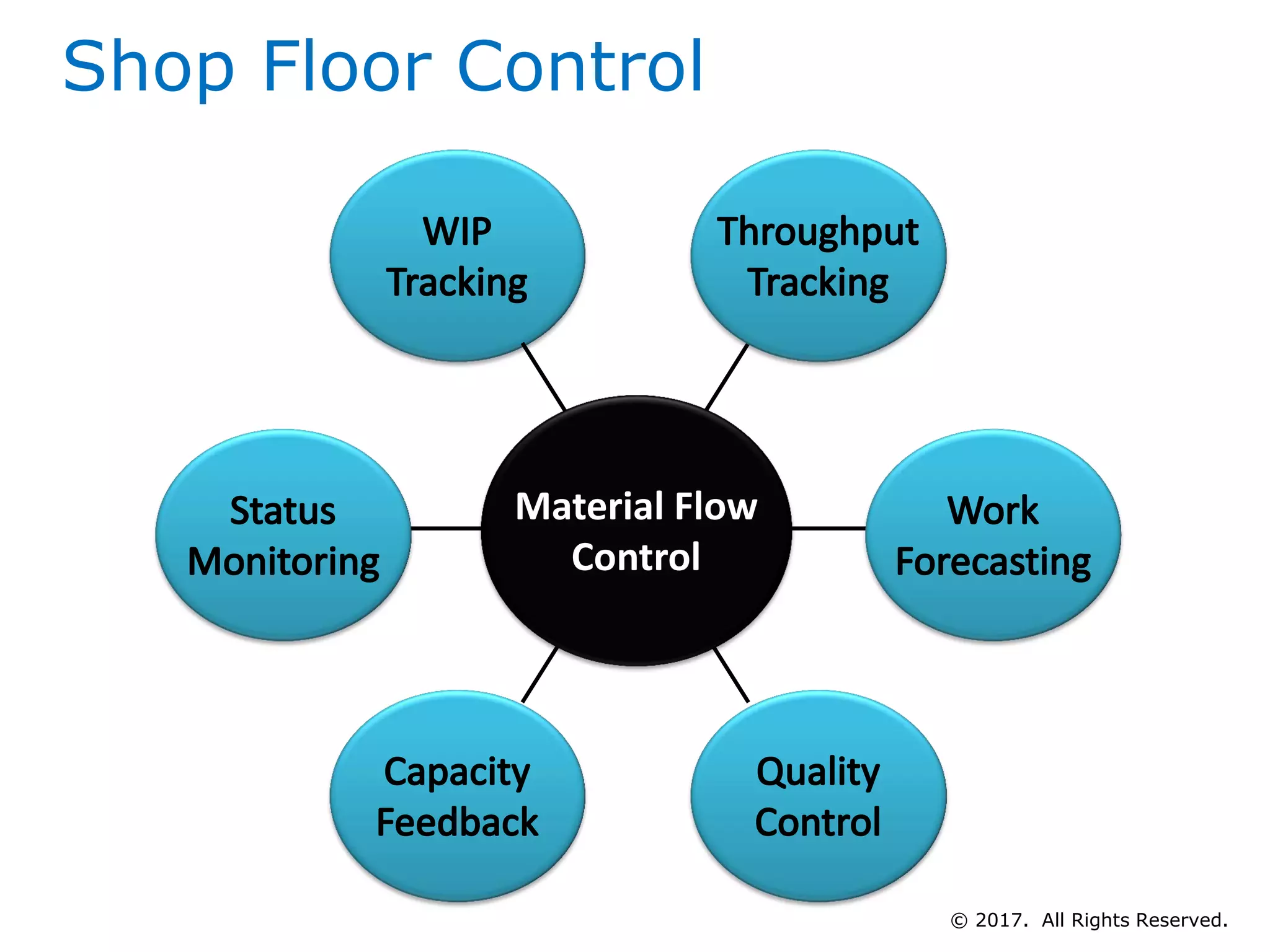

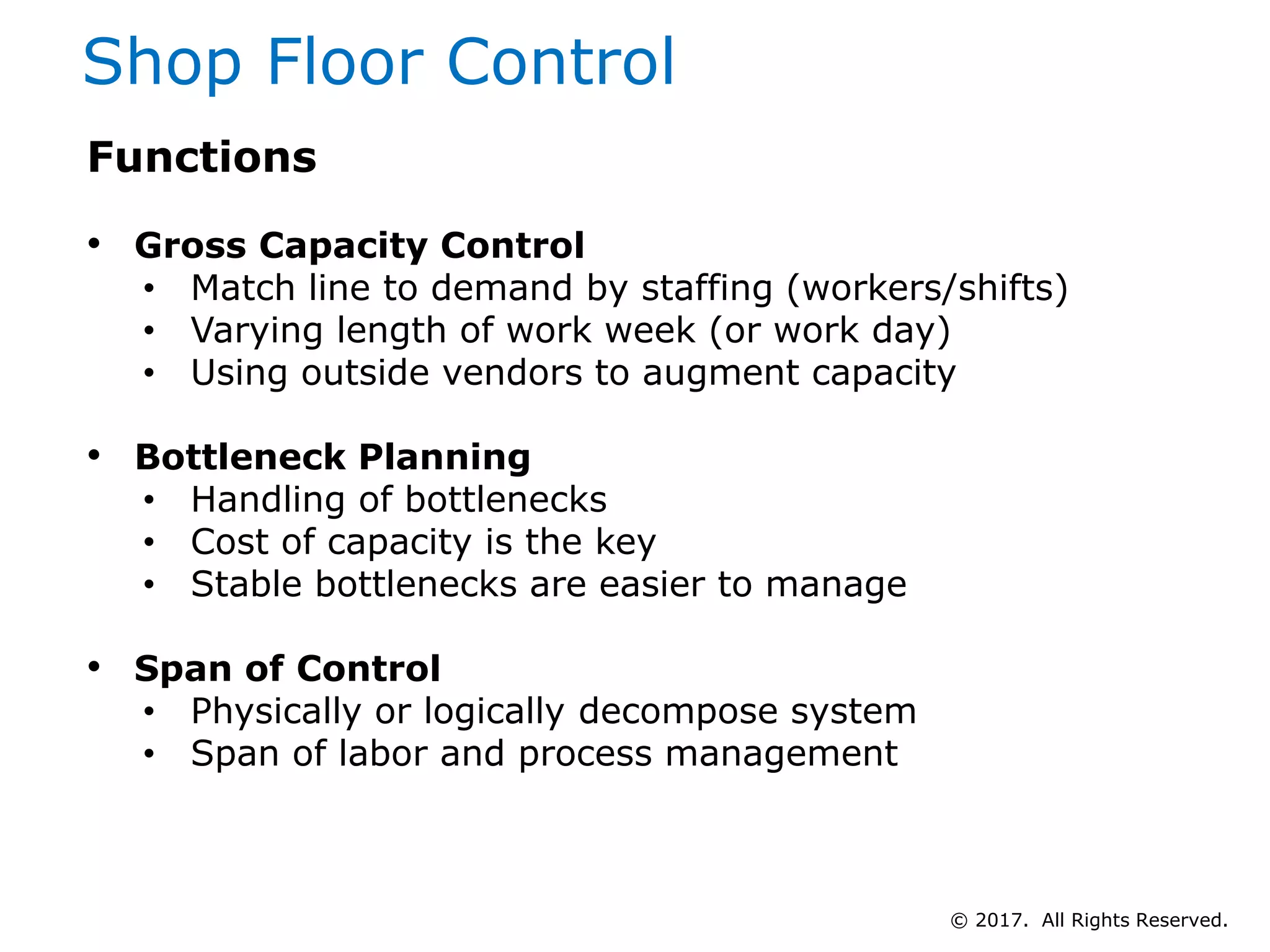

The document discusses the essential components of production planning and control, emphasizing its importance in forecasting, resource management, and efficiency in manufacturing operations. It details various planning strategies, including aggregate production planning, workforce planning, and material requirement planning, as well as different scheduling and production control methodologies such as Just-In-Time (JIT) systems. Additionally, it highlights the significance of dispatching, follow-up, inspection, and corrective measures to ensure adherence to production schedules and maintain quality.