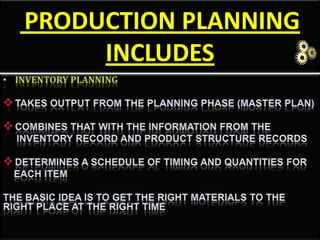

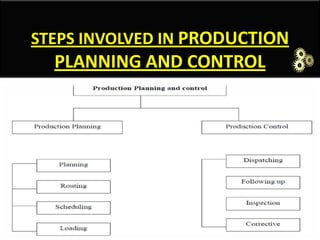

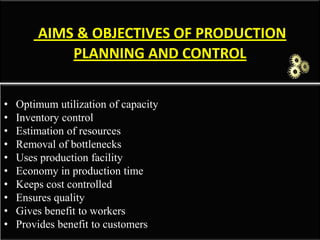

Production planning is the process of determining the necessary resources for future operations, focusing on the acquisition, utilization, and allocation of production facilities, labor, and materials. It involves scheduling, inventory control, and ensuring quality while optimizing costs and productivity. The use of Just-In-Time (JIT) techniques helps minimize waste and improve efficiency in production processes.