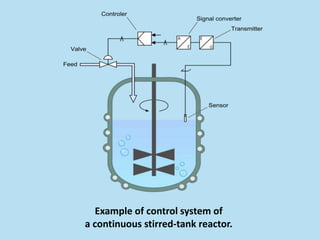

Process control involves using computers or microprocessors to control industrial processes. There are three main types of process control: batch process control which combines specific amounts of raw materials together for a set time like making prepackaged meals; continuous process control which regulates uninterrupted processes like fuel production; and discrete process control which produces specific items through manufacturing applications like robotic assembly lines. Process control is used across many industries like oil refining, chemicals, food production, and automotive manufacturing.